Front demounting structure of LED module

An LED module, front dismantling technology, applied in the chassis/cabinet/drawer parts, instruments, identification devices, etc., can solve the problems of error-prone, time-consuming, etc., achieve a simple and compact structure, reduce the installation environment. Requirements, the effect of simplifying the space structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

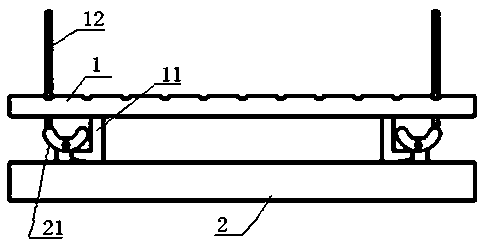

[0024] Such as figure 1 As shown, a front detachable structure of an LED module includes a front module 1 and a rear module 2 respectively installed on the LED display screen, the front module 1 is provided with a front buckle 11, and the rear module is provided with a rotating spring Mechanism 21, by pushing the front module 1, the front buckle 11 pushes one end of the rotary spring mechanism 21 to rotate to realize the fastening between the front buckle 11 and the rotary spring mechanism 21, and the jig 12 is also movably installed on the front module 1. The tool 12 pushes the other end of the rotating spring mechanism 21 to rotate out of the fastening of the front buckling member 11 so as to pull out the front module 1 .

[0025] The specific working process is as follows:

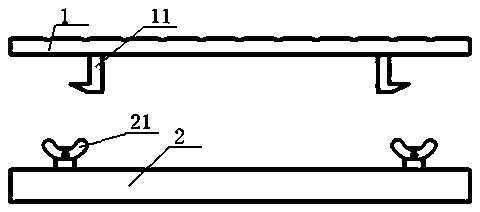

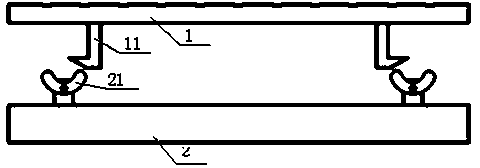

[0026] Such as Figure 2-3 As shown, when installing, push the front module 1 to move toward the rear module 2, the front buckle 11 on the front module 1 pushes one end of the rotary spring mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com