A cotton picker

A cotton-picking and cotton-picking needle technology is applied in the fields of picking machines, agricultural machinery and implements, and applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

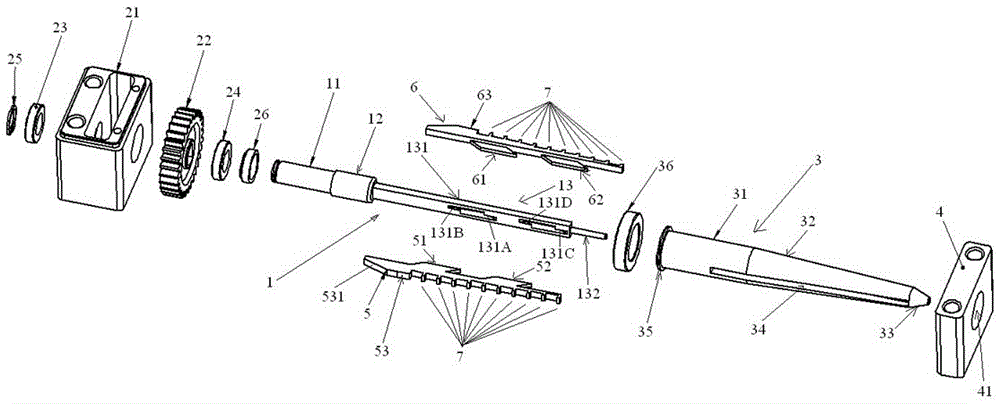

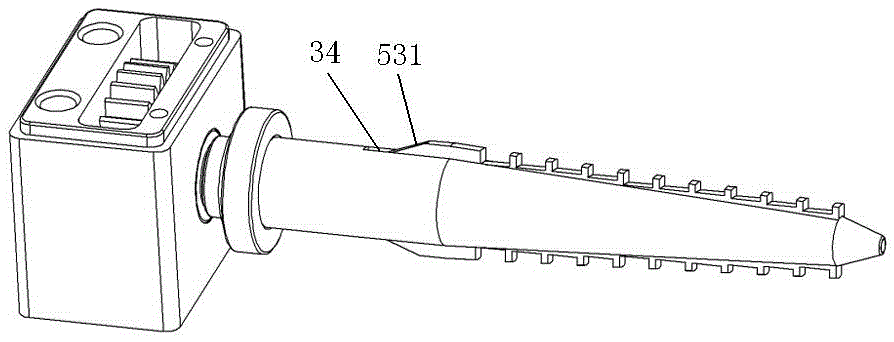

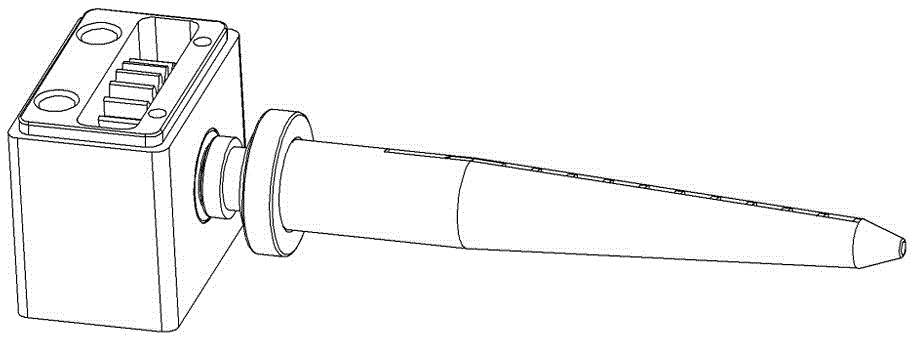

[0034] see figure 1 , the present embodiment is a preferred embodiment of the present invention, it provides a kind of cotton picking spindle, including the following components:

[0035] The central shaft 1 is used to rotate with the drive of the driving device, wherein the driving device can be any commonly used driving device, for example, in this embodiment, the driving device is a gear box driven by a motor; specifically, the central shaft 1 It consists of three parts: the cylindrical connecting shaft part 11 connected with the drive assembly, the round table part 12 connected with the outer casing part, the assembly part 13 for installing the cotton picking part, and the assembly part 13 includes a piece for installing the cotton picking needle part Shaped part 131 and needle-shaped part 132 at the front end; wherein, the gearbox drive assembly specifically includes a gearbox case 21, a drive gear 22, a first connection bearing 23 and a second connection bearing connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com