Dirty oil and sewage discharge device for diesel engine bench experiment

A technology of a relief device and a bench experiment, applied in the direction of internal combustion engine testing, etc., can solve problems such as pollution, and achieve the effects of low cost, saving pipes and valve parts, and easy hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

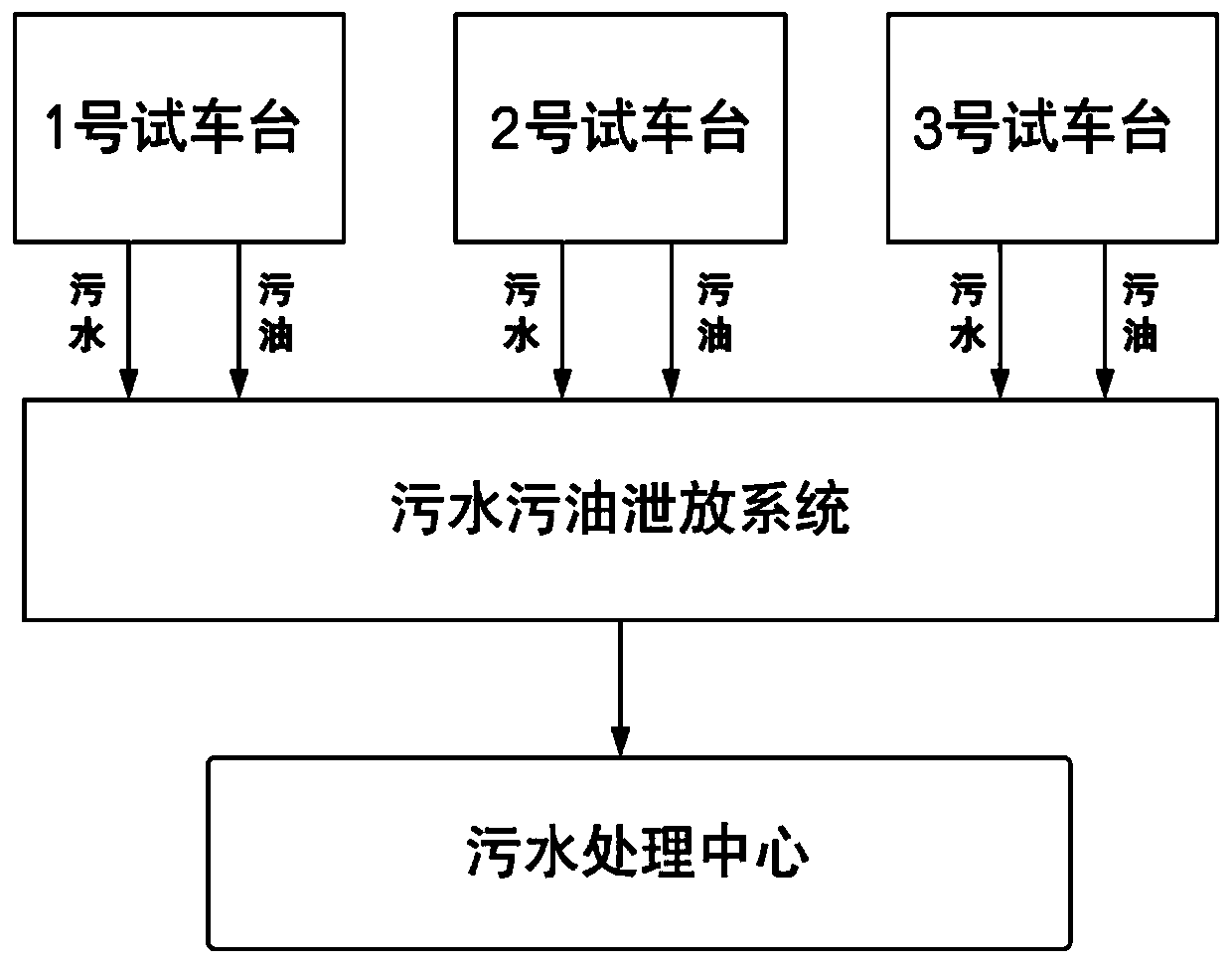

[0026] The diesel engine bench experiment shown in the figure is connected to three test benches with a dirty oil and sewage discharge device, and the main engine of the diesel engine is placed on the test benches.

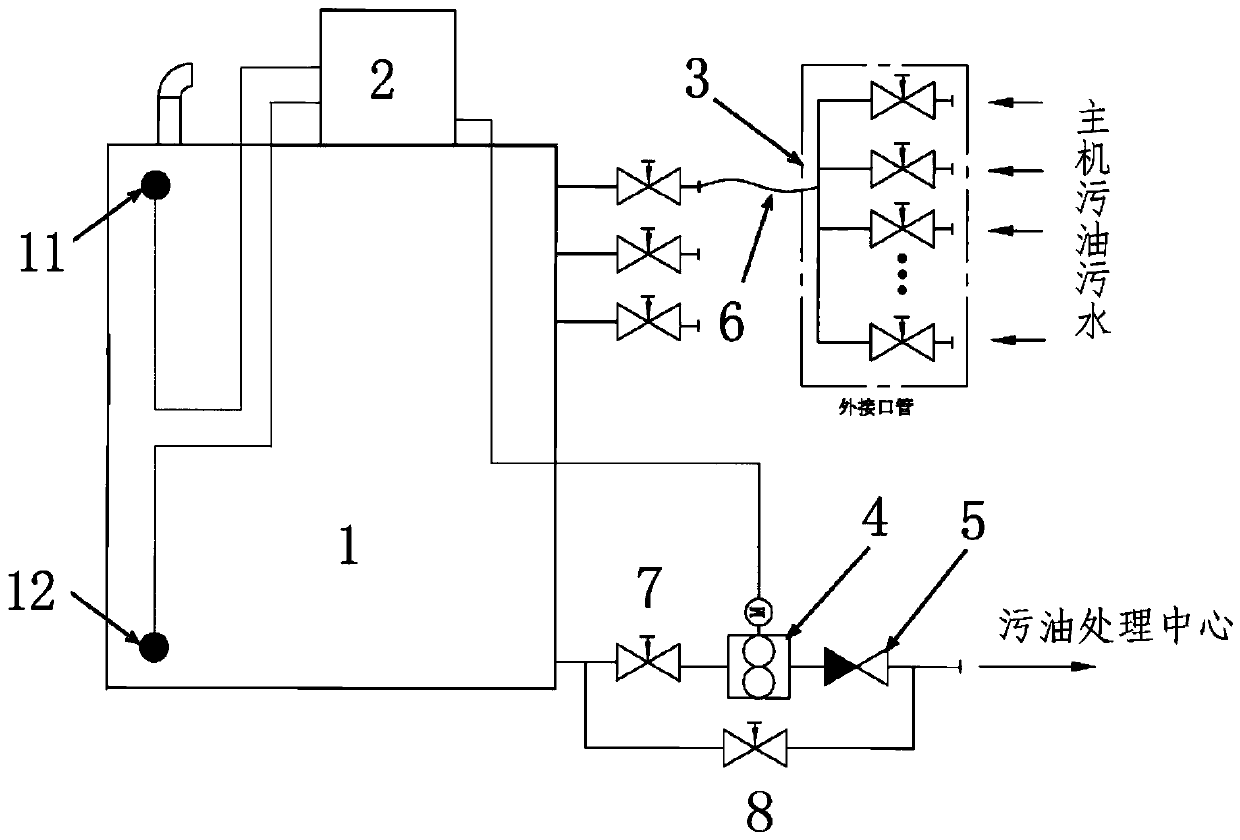

[0027] see figure 2 , the oily sewage discharge device adopts a skid-type modular structure, including a dirty oily sewage collection box 1, a delivery main pipe 6, a delivery pump 4, an external piping system 3 and an electric control box 2.

[0028] The external pipe system 3 is used to collect the dirty oil and sewage generated when the diesel engine main frame motor vehicle, including a plurality of collection pipes; the upstream of the plurality of collection pipes are respectively connected to the discharge ports of each test stand , the number of the collection pipes is determined according to the size of the main engine and the amount of dirty oil and sewage. The downstream of the plurality of collection pipes is connected to the delivery main pipe 6 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com