Antique building arch prefabricated reinforced skeleton and its manufacturing method and construction method of antique architectural reinforced concrete arch

A technology of reinforced concrete and steel skeleton, which is applied in the processing of building materials, construction, building structure, etc., can solve the problem that the welding and installation quality of embedded parts is difficult to guarantee, the process of bucket arch beam reinforcement cage is cumbersome, and the assembly operation is dangerous, etc. problems, to achieve the effect of saving labor and material costs, shortening the construction period, and reducing the construction operation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

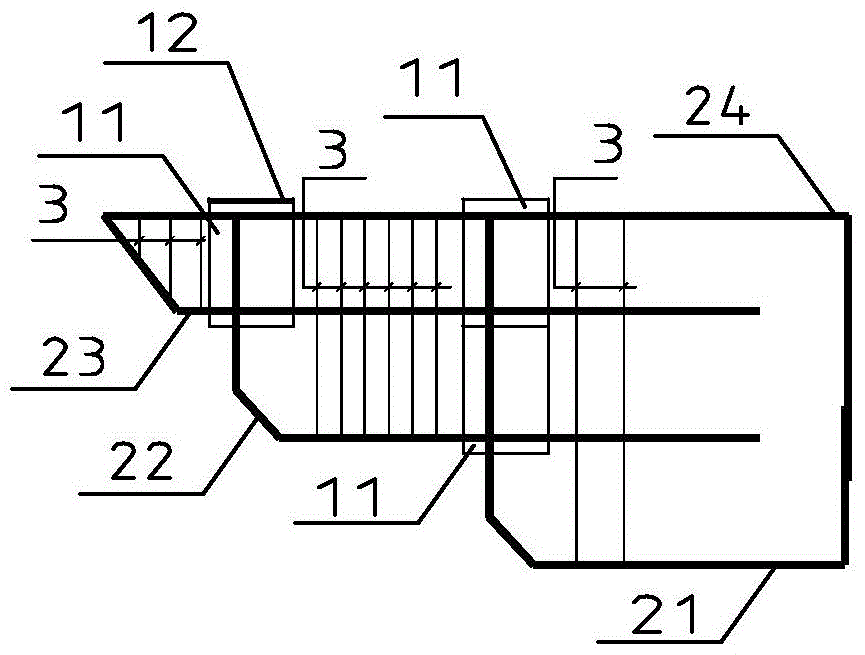

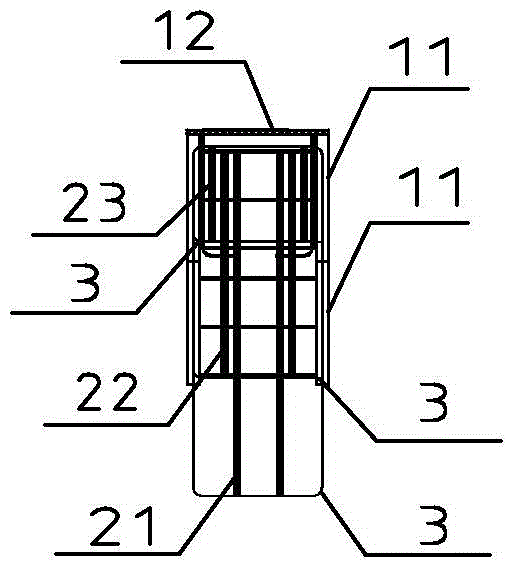

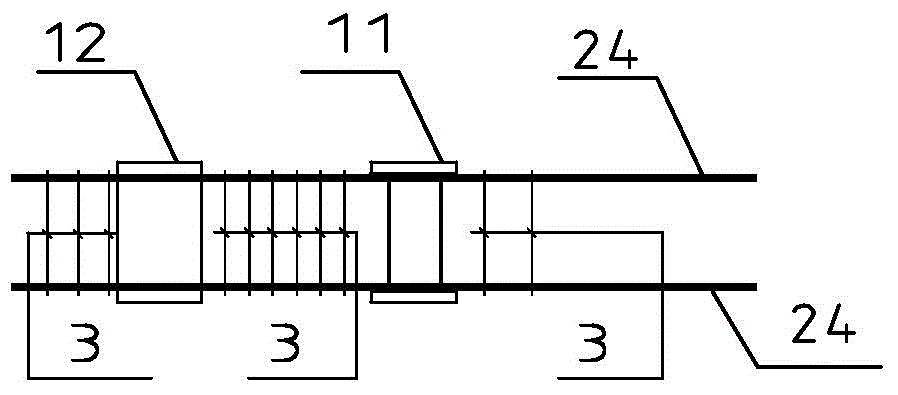

[0064] A prefabricated reinforced skeleton of bucket arches of an antique building, such as Figure 1-1 to Figure 1-3 As shown, the bucket arch prefabricated steel skeleton is composed of the embedded parts system 1, the bucket arch skeleton reinforcement system 2 and the bucket arch stirrup 3, which is an integral reinforcement cage whose cross-sectional area decreases from one end to the other for the second time;

[0065] The embedded part system includes a double-sided rectangular steel plate embedded part 11, a single-sided rectangular steel plate embedded part 12 (see Figure 2-1~Figure 2-2 ); its role is to fix and support the main stress steel bars, and to connect with the wooden structure after the concrete is poured;

[0066] The bucket arch skeleton reinforcement system 2 includes bottom main reinforcement 21, middle main reinforcement 22, upper main reinforcement 23 and gluten 24, and its function is to form the main stress system of the bucket arch for bearing and ...

Embodiment 2

[0070] A method for making a bucket arch prefabricated reinforced skeleton with steel plate embedded parts in an antique building. The method is a method for making the bucket arch prefabricated reinforced skeleton of the antique building described in Example 1 on the ground. It uses double-sided rectangular steel plate embedded parts as Temporary support system, penetrating and welding the main reinforcement of the bucket arch beam to form a reinforcement skeleton, and finally installing stirrups and single-sided rectangular steel plate embedded parts outside the reinforcement skeleton to form an integral reinforcement cage; it includes the following steps: (see Figure 3 ~ Figure 6 )

[0071] A. Construction preparation, measurement and stakeout: Prepare the steel bar material and steel plate embedded parts of the prefabricated steel bar skeleton of the bucket arch; according to the construction drawings, clarify the relative positions of the bucket arch reinforcement and ste...

Embodiment 3

[0086] A construction method for the reinforced concrete bucket arch of an antique building. The method is to process the reinforced concrete bucket arch steel skeleton of the antique building reinforced concrete bucket arch on the ground as a whole, then hoist and install it as a whole, anchor it into the frame column and anchor it into a whole, and then perform concrete pouring. , including the following steps:

[0087] (1) Make the prefabricated steel skeleton of the reinforced concrete bucket arch of the antique building on the ground (see Figure 1- Figure 6 ):

[0088] The method for making the prefabricated steel skeleton of the bucket arch of the reinforced concrete bucket arch of the antique building on the ground is the method for making the prefabricated steel skeleton of the bucket arch of the antique building with steel plate embedded parts described in embodiment two; no more details here;

[0089] (2) Overall lifting and installation:

[0090] Lift the finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com