Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire sidewalls, transportation and packaging, etc. It can solve the problem of not being able to obtain the visual hiding effect of the concave part, and achieve the effect of improving the visual hiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

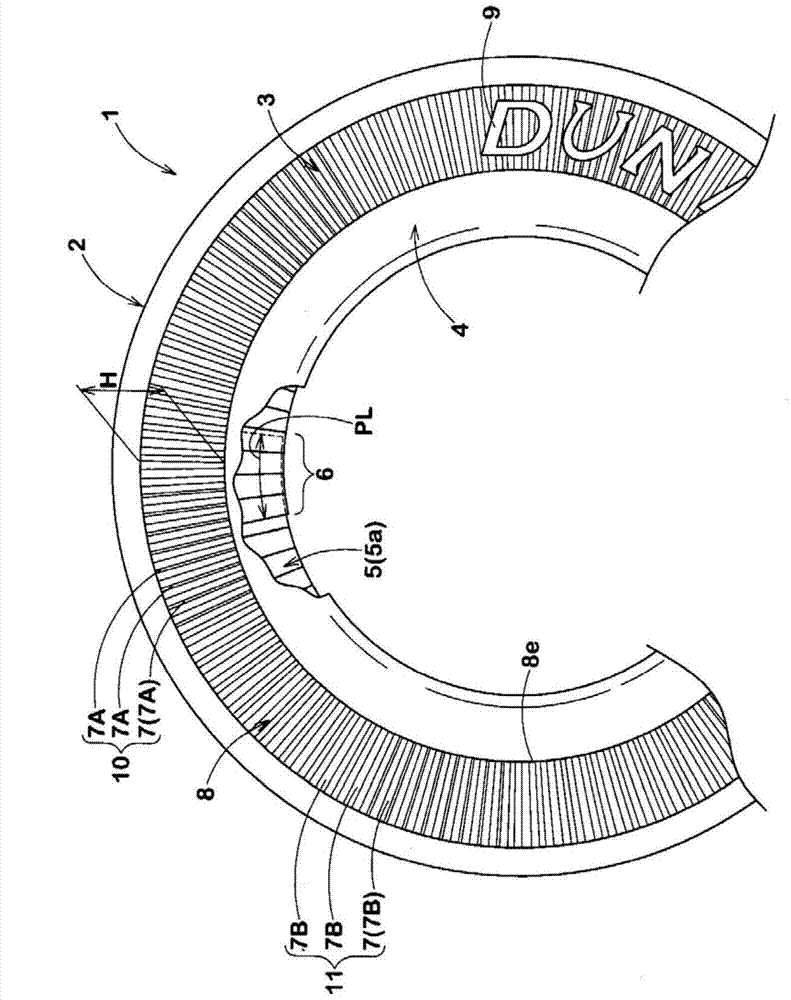

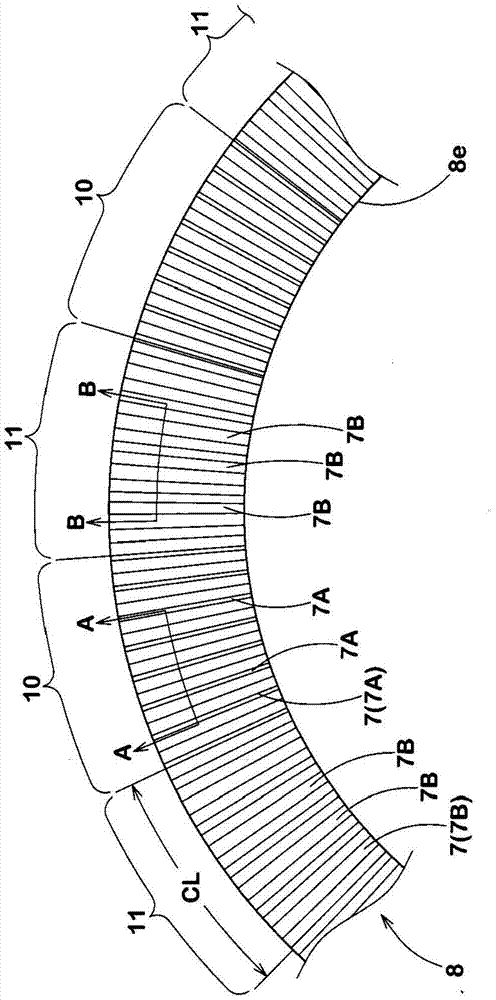

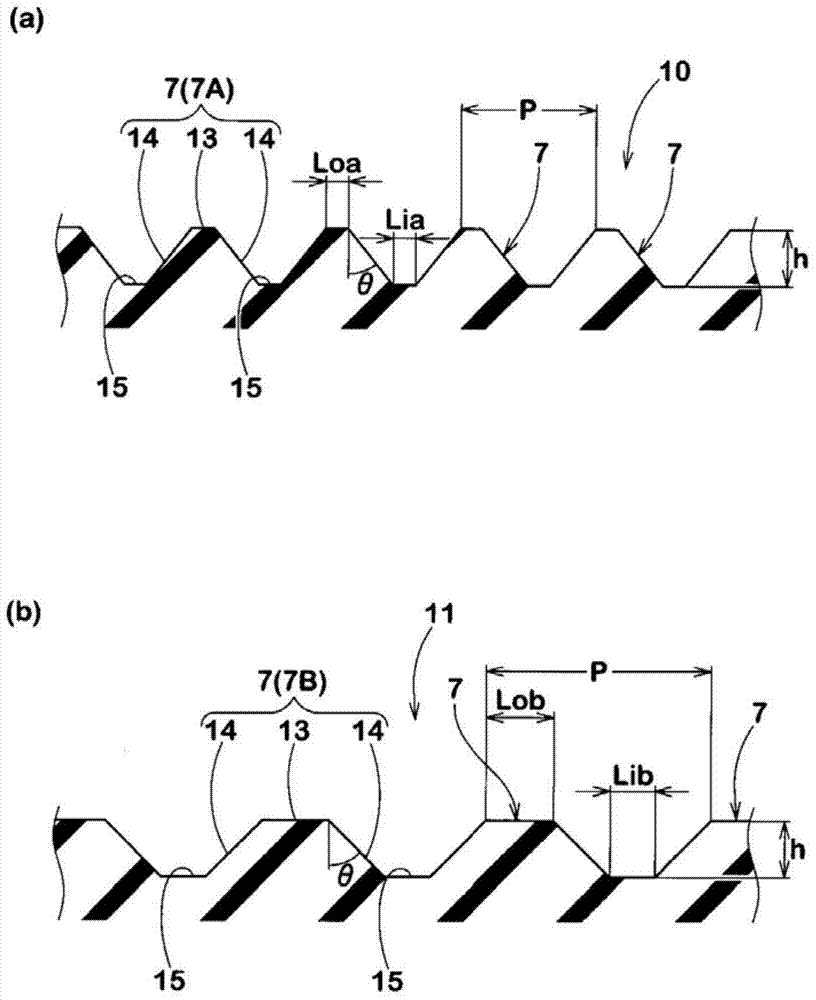

[0044] In order to confirm the effects of the present invention, various pneumatic tires with a size of 175 / 60R14 were trial-produced based on the specifications in Table 1, and an appearance evaluation test of the sidewall portion was performed. The number of carcass plies in this pneumatic tire is one, and the length PL of the joint portion of the carcass plies at the inner edge of the decorative pattern is 12 mm. The decorative pattern is formed by arranging the first ridge group and the second ridge group alternately. Accordingly, a region where a decorative pattern is formed and a region where a decorative pattern is not formed are intentionally provided on the sidewall portion. In addition, see Image 6 As shown, three types of ridges are used in the present embodiment as ridges of the ridge group.

[0045] In addition, in the appearance evaluation test, 5 testers visually compared the area where the decorative pattern was formed and the area where the decorative patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com