Method of manufacturing seat windshield

A windshield and seat technology, which is applied in the field of parts manufacturing, can solve the problems of low overall strength of the seat windshield, increased production costs, and waste of materials, etc., so as to prevent passengers from sliding down and facilitate production The effect of manufacturing and ensuring comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

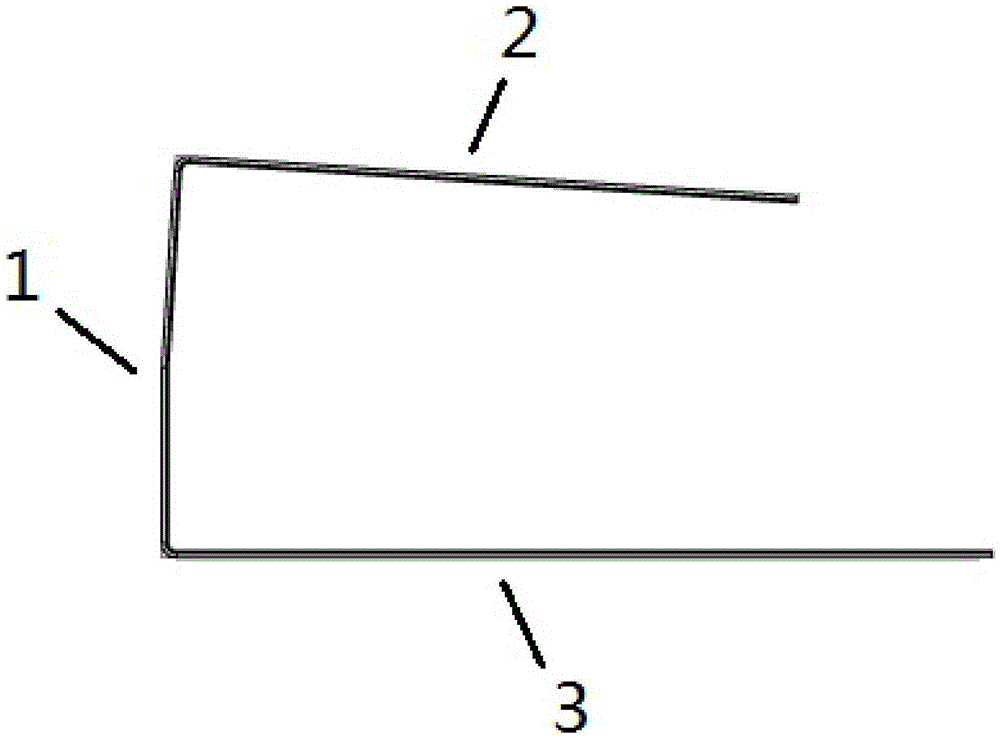

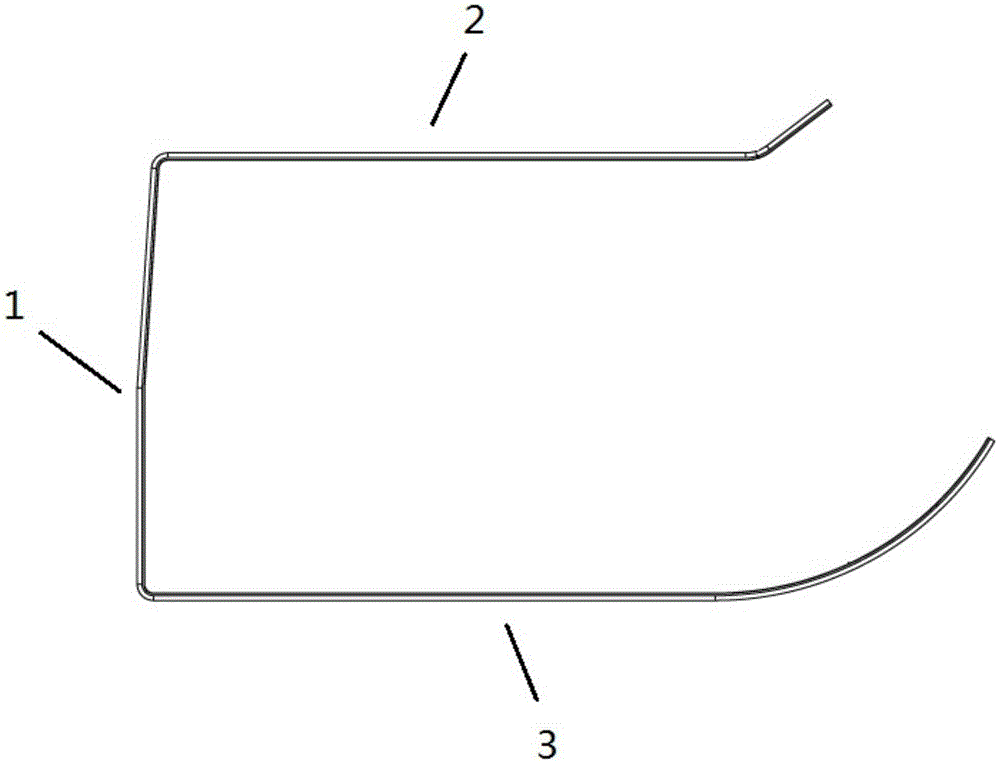

[0029] The method for manufacturing seat windshield of the present invention, as Figures 1 to 8 As shown, it is mainly divided into two parts.

[0030] Part 1: First use a long profile to make the frame of the windshield.

[0031] First bend the middle part of a long profile, and the bend is an obtuse angle, so that the backrest part of the windshield can be tilted forward.

[0032] Then bend the top and bottom of the bend forward at the same time, and the new bend is a smooth transition, forming the back panel 1 located at the rear, the upper panel 2 located at the upper part and the lower panel 3 located at the lower part, and the upper panel 2 is at a right angle to the upper part of the back panel 1, and the lower panel 3 is at a right angle to the lower part of the back panel 1, so that the distance between the upper panel 2 and the lower panel 3 is moderate, preparing for the next step, and making the next step The mold of the process is more compact, saving the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com