Body-in-white engine cabin flow tank structure

A technology of flow trough structure and body-in-white, which is applied to the superstructure, superstructure sub-assemblies, vehicle parts, etc., can solve the problems of water inflow into the cabin, the effect of sealing is not very good, and the rainwater is easy to corrode, so as to facilitate maintenance. , Improve the ability to store and divert the rainwater from the front windshield, and avoid the effect of rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

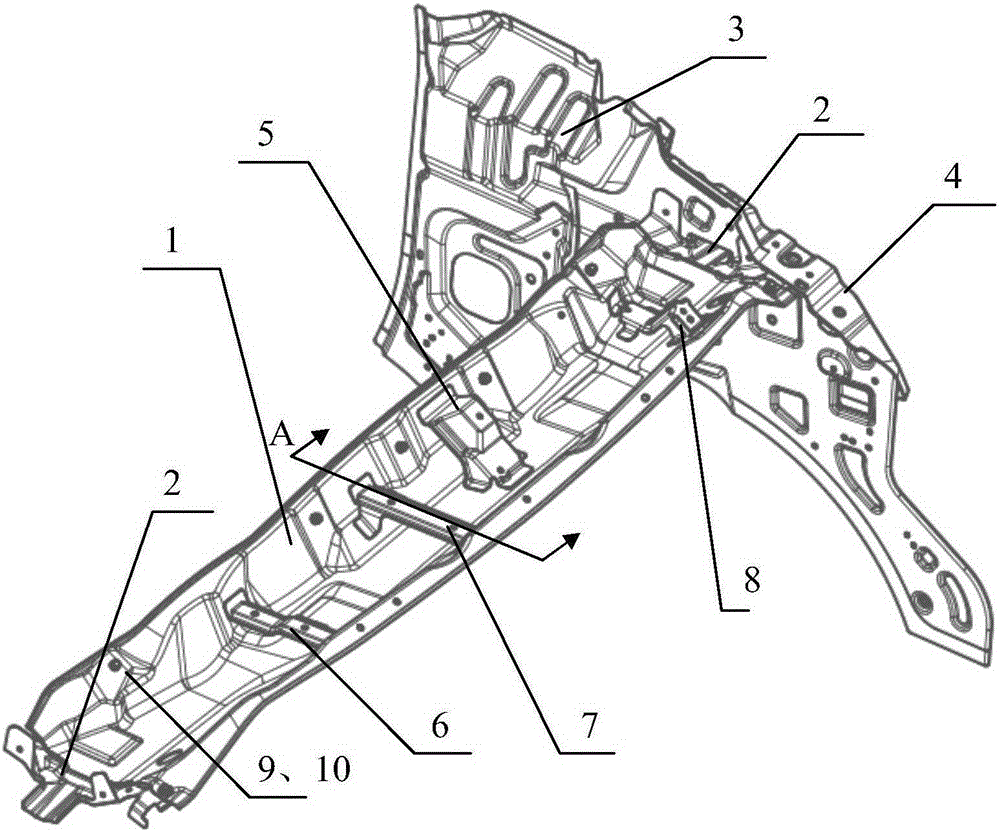

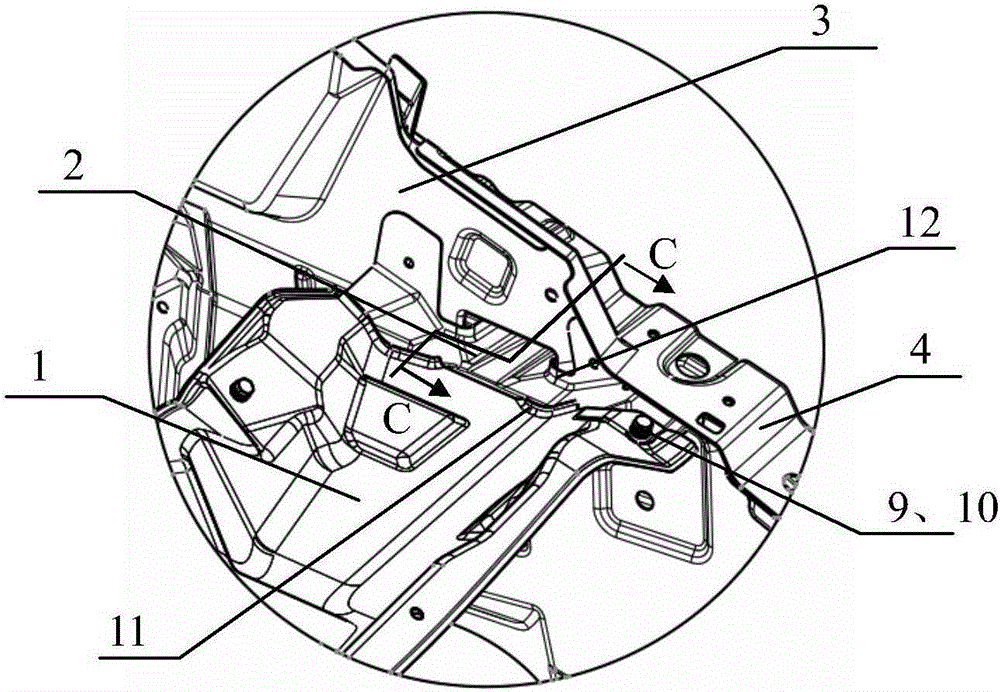

[0024] A body-in-white engine cabin flow tank structure, such as figure 1 As shown, it includes a water tank body 1, a side sealing plate 3 and a supporting plate 4 on the side of the engine room. (Note: Engine compartment is the abbreviation of engine compartment, which is a technical term known in the art)

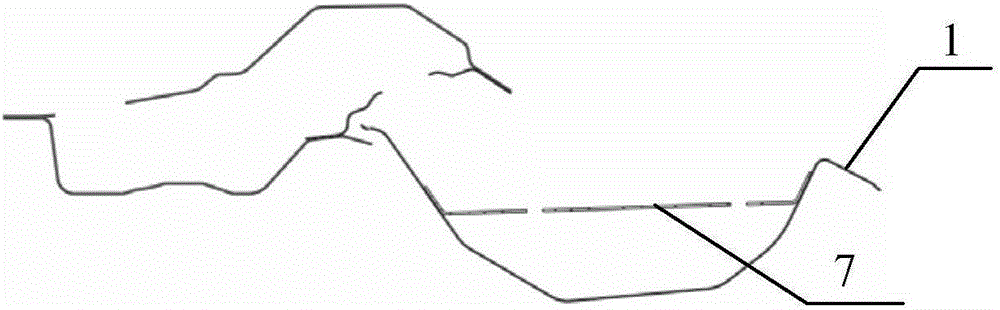

[0025] Such as figure 1 and Figure 4 As shown, the longitudinal section of the water tank body 1 is U-shaped, the middle part is high, the two ends are low, and the two ends are provided with upward diversion flanges 11. The height of the diversion flanges 11 is 10mm, and the main function is to store rainwater. and pre-flow. The shape of the water tank body 1, the setting of the diversion flange 11 and its height of 10 mm are the preferred design and value of this embodiment, and those skilled in the art can also set them by themselv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com