Non-damage conveying, cutting and washing system of bananas

A cleaning system, banana technology, applied in transportation and packaging, manual conveying devices, food processing, etc., can solve problems such as quality appearance decline, banana collision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

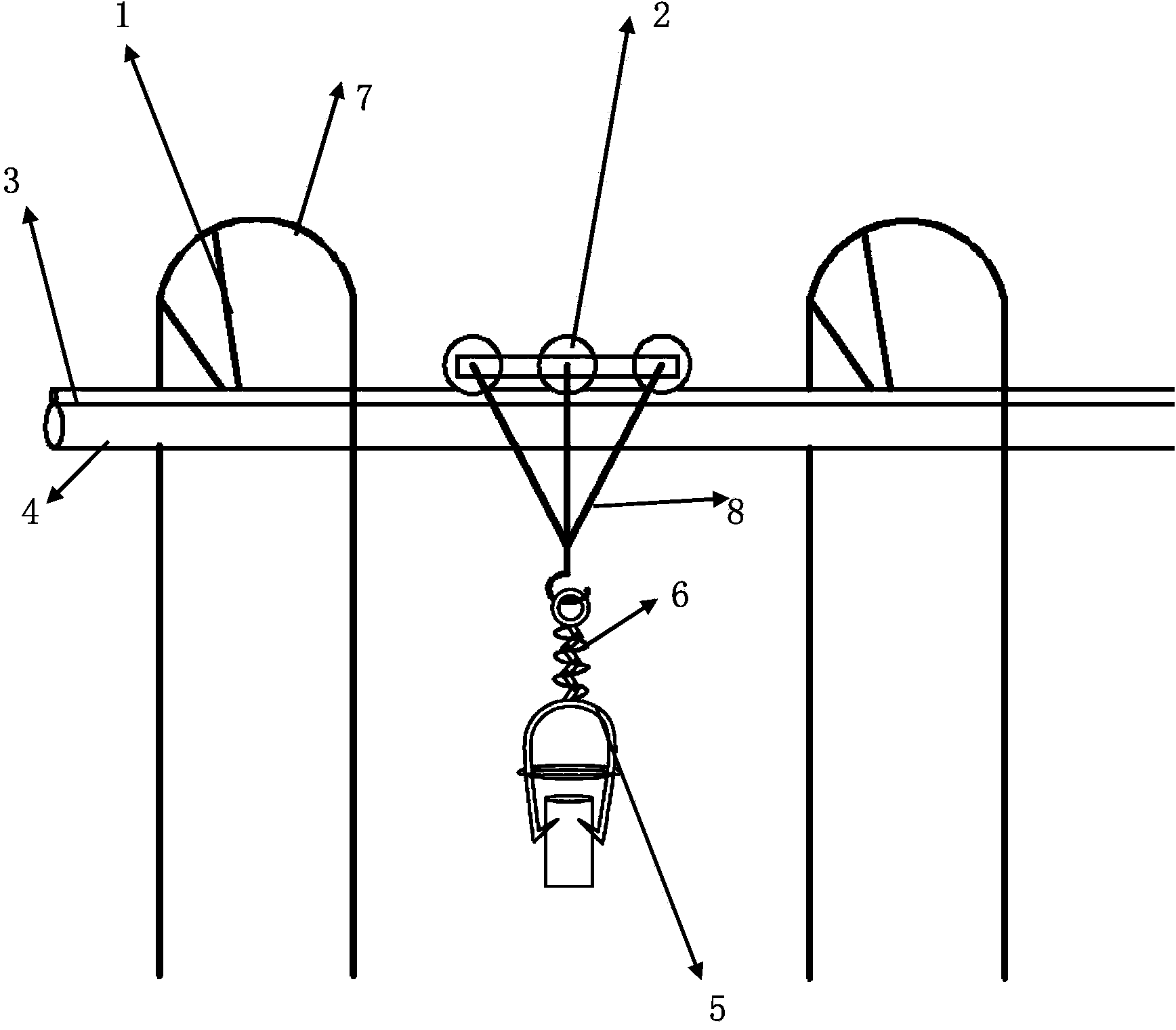

[0016] A banana harvesting and cleaning system for non-injury transportation, in figure 1 Among them, it includes a conveying device, a cutting knife and a cleaning device, wherein the conveying device includes: a track bracket, the inner upper part of the track bracket is fixedly connected to at least one support rod, and the end of the support rod is detachably connected to the guide rail seat; the guide rail is fixedly installed On the guide rail seat, the guide rail and the guide rail seat are arranged in a ring shape and are divided into two arc parts, one of which is the banana harvesting arc part, the other is the banana cleaning arc part, and two straight parts; the pulley block, It includes at least two pulleys, and the plurality of pulleys are connected by a solid rod drawn from the pulley shaft. The solid rod is provided with a hook and a fixing device. The top is a connecting rod hanging on the hook, and the lower end of the connecting rod is connected to Fixer, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com