Two-way brake safety caliper

A technology of safety gear and braking part, which is applied in elevators, transportation and packaging, etc. It can solve the problems of elevator safety hazards and elevators without safety protection, and achieve the effects of preventing interference, convenient up and down positions, and auxiliary guiding functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

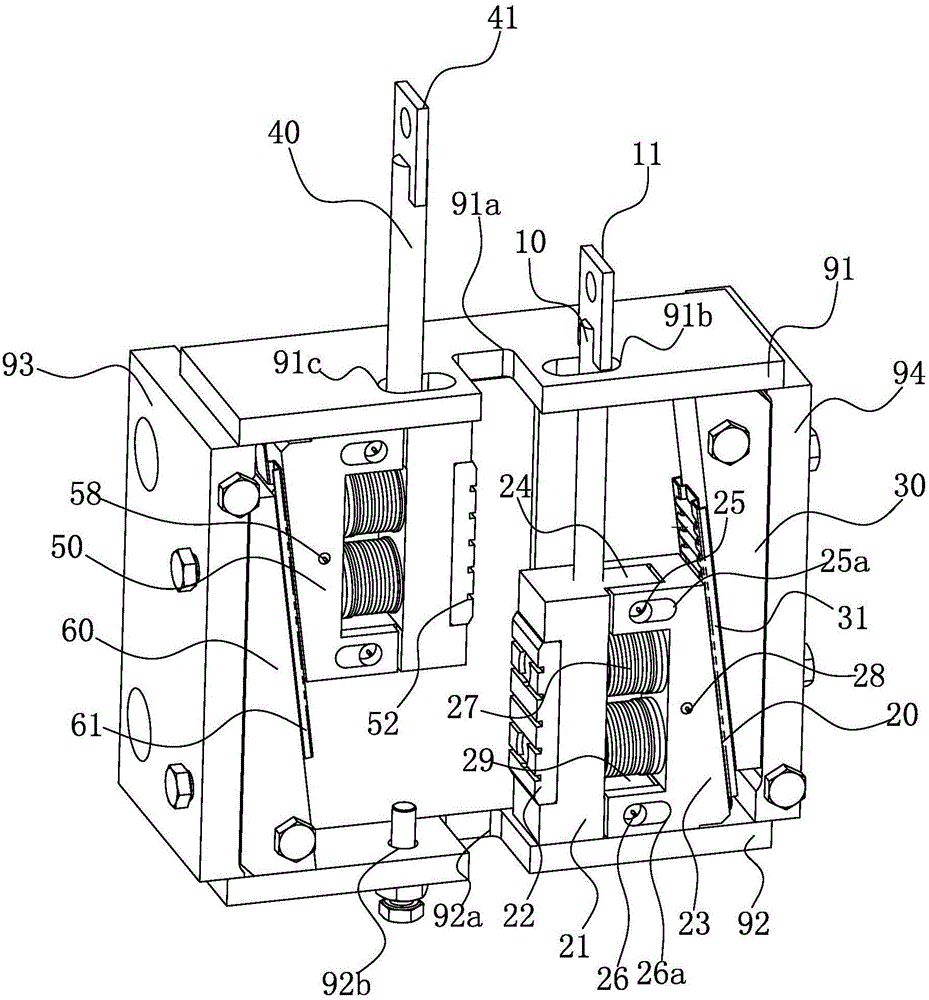

[0019] Such as figure 2 with Figure 4 As shown, the bidirectional braking safety gear of the present invention includes an upper shell 91, a lower shell 92, a left shell 93, a right shell 94, a right pull rod 10, a right braking part 20, a right needle roller seat 30 and a right needle roller plate 31. The upper case 91 is provided with an upper case U hole 91a, and the lower case 92 is provided with a lower case U hole 92a. The upper casing U hole 91a and the lower casing U hole 92a are covered with the elevator guide rail 8 , and also include the left tie rod 40 , the left braking part 50 , the left needle roller seat 60 and the left needle roller plate 61 .

[0020] The lower part of the right tie rod 10 passes through the right oblong hole 91b of the upper shell and is fixedly connected with the upper end surface of the right brake part 20 . The top of the right tie rod 10 is fixedly connected to the bottom of the right connecting rod 11, and the upper part of the righ...

Embodiment 2

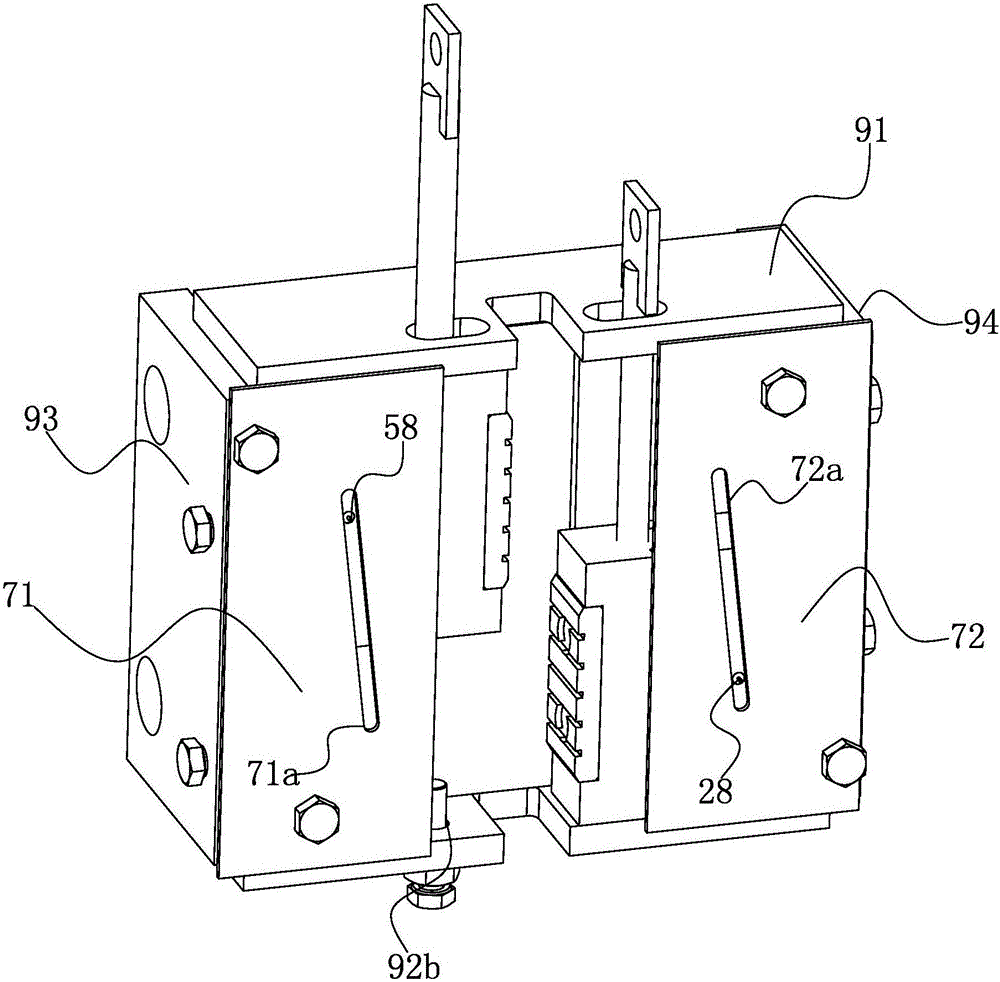

[0033] Such as image 3 As shown, the difference between the second embodiment and the first embodiment is that the left cover 71 and the right cover 72 are provided on the front sides of the left shell 93 and the right shell 94 . The left cover plate 71 is fixedly connected with the left needle roller seat 60 . The right cover plate 72 is fixedly connected with the right needle roller seat 30 . A left pin 58 is provided on the front end surface of the left brake part 50 . The left cover plate 71 is provided with a left elongated hole 71a matched with the left pin 58, and the left pin 58 is movably connected with the left elongated hole 71a. The left elongated hole 71 a is parallel to the left end surface of the left brake part 50 . A right pin 28 is provided on the front end surface of the right brake part 20 . The right cover plate 72 is provided with a right elongated hole 72a matched with the right pin 28, and the right pin 28 is movably connected with the right elonga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com