Overall heating device for automotive stabilizer bar with variable-section end part

A technology of overall heating and stabilizing rods, which is applied in the direction of heat treatment furnace, heat treatment equipment, process efficiency improvement, etc., to achieve the effect of precise control of heating temperature, avoiding fatigue failure, and avoiding heat energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

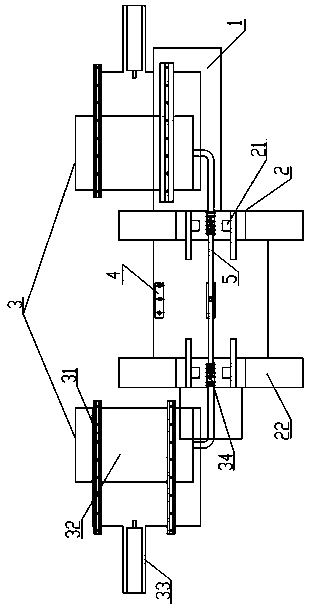

[0022] figure 1 A preferred embodiment of the overall heating equipment of the automobile stabilizer bar of the present invention is shown. The heating device 2 is provided with two pairs of heating electrodes 21 , and the heating electrodes are arranged on the frame 1 through two electrode supports 22 , and can clamp and heat the middle part of the stabilizing rod 5 . Described supersonic heating device 3 quantity is two and is symmetrically arranged on both sides of frame 1, and supersonic heating device 3 comprises supersonic heating machine 32, and this supersonic heating machine is arranged on two rolling linear guide rails 31, rolling straight line The guide rail 31 is arranged on the frame 1, and the rolling linear guide 31 is a narrow rolling linear guide with equal load in four directions, which can ensure that the reciprocating linear motion of the super audio heating machine 3 is stable and reliable; the rolling linear guide 31 is also provided with a cylinder 33, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com