Textile cleaning device

A technology for cleaning devices and textiles, which is applied in the field of textile devices, and can solve problems such as affecting the environment, affecting the appearance, and falling debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

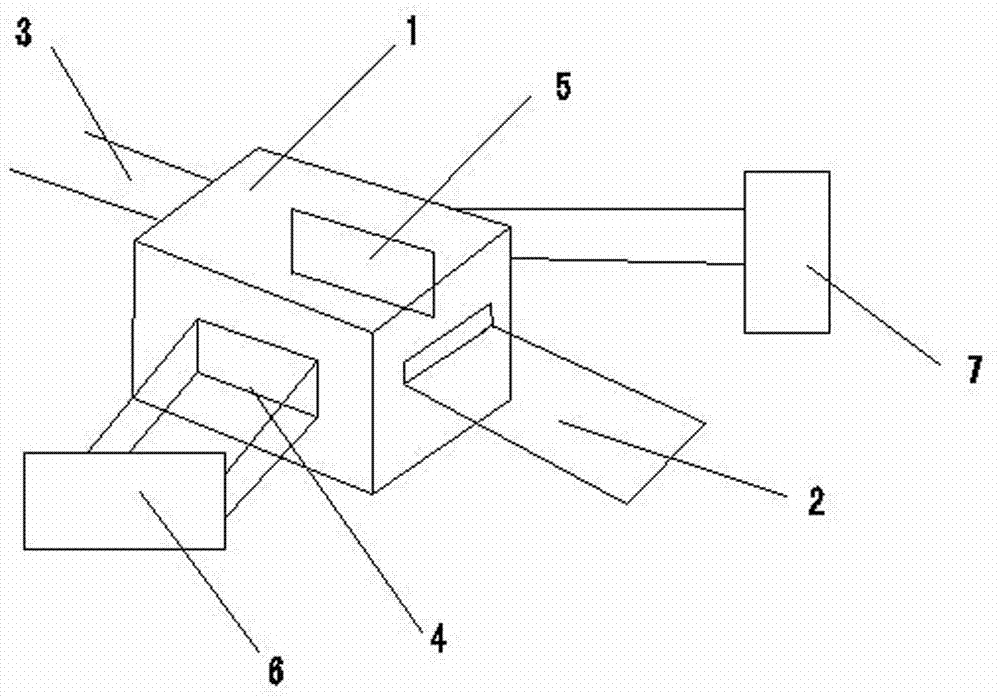

[0014] A textile cleaning device, comprising a cabinet 1, a feeding platform 2 and a discharging platform 3, the feeding platform and the discharging platform are respectively located at both ends of the cabinet, and the two sides of the cabinet 1 perpendicular to the moving direction of textiles are respectively provided with outlets. The air outlet 4 and the air suction port 5 , the air outlet 4 is in sealing connection with the air outlet device 6 , and the air suction port 5 is in sealing connection with the air suction device 7 . The textile enters the cabinet 1 from the feeding table 2, blows the air through the air outlet 4 on one side of the cabinet, blows up the wool, small thread ends and other sundries on the textile, and then sucks the sundries out through the air suction port 5 on the other side of the cabinet 1, so that Textile surfaces are cleaner.

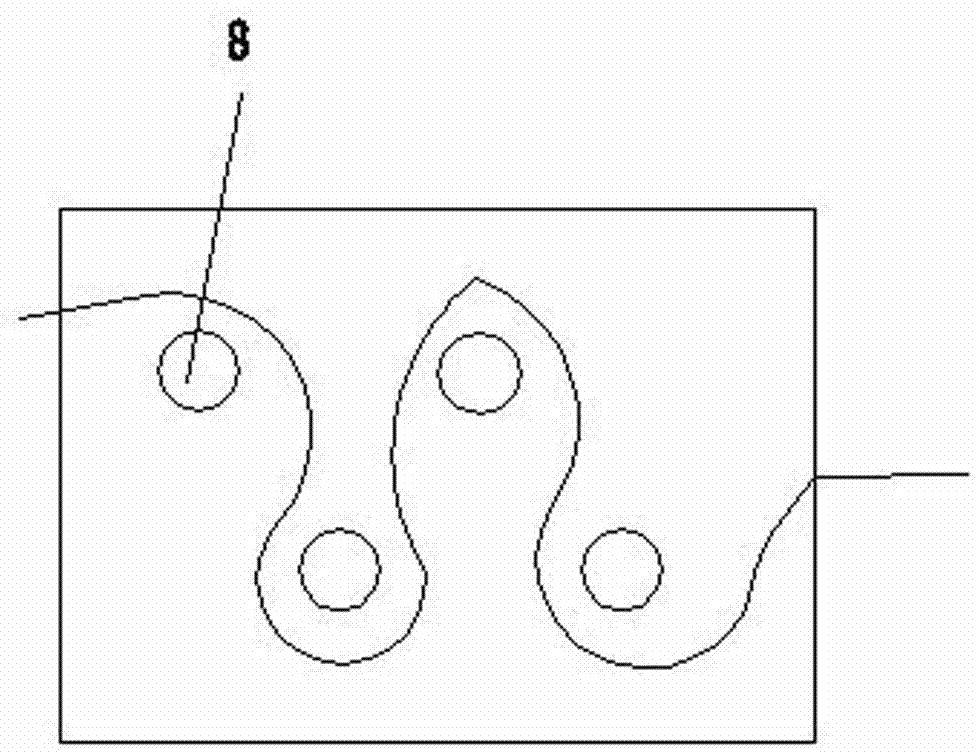

[0015] The cabinet 1 is provided with several sets of vertically staggered roller columns 8, the roller columns 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com