PCB (printed circuit board) positioning and blowing jig

A PCB board and jig technology, applied in the field of PCB board positioning blowing jigs, can solve the problems of affecting the use effect of PCB boards, shortening the service life of PCB boards, and easy movement of PCB boards, so as to achieve firm fixation, ensure the use effect, Easy to blow on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

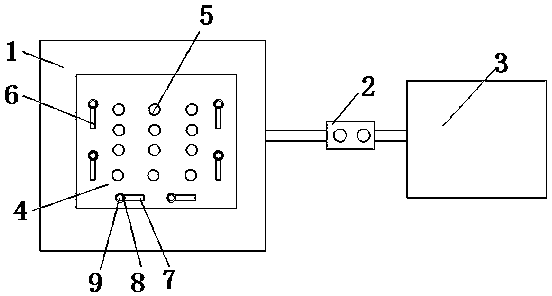

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, a PCB board positioning air blowing jig includes a base 1, an air blowing solenoid valve 2, an air compressor 3 and a rotating baffle 6, a boss 4 is arranged on the base 1, and at least two on the top of the boss 4 Rotating baffles 6 are provided in two directions, and at least two rotating baffles 6 are provided in each direction. The rotating baffle 6 includes a retaining bar 7, a movable bushing 8 and a positioning shaft 9, the retaining bar 7 is socketed on the positioning shaft 9 through the movable bushing 8, and the retaining bar 7 takes the positioning shaft 9 as a fulcrum for 360° turn. Bar 7 and movable axle sleeve 8 all adopt insulating material to make.

[0014] Four rows of air blowing holes are arranged on the area of the boss 4 surrounded by each rotating baffle plate 6 , and each row of air blowing holes includes thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com