Double-web H-shaped steel type buckling restraint brace

A buckling restraint, H-beam technology, applied in the direction of building components, earthquake resistance, etc., can solve the problem of not taking into account, and achieve the effect of reducing the buckling length, reducing the amount of steel used, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

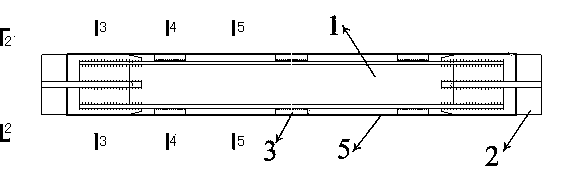

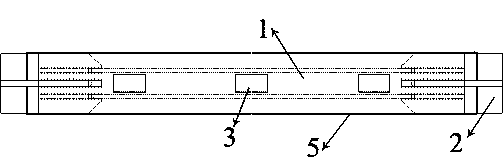

[0022] like Figure 1-Figure 6 Shown: a double-web H-shaped steel buckling-constrained support, which includes a double-web H-shaped steel 1 and a rectangular sleeve 5 sleeved outside the double-web H-shaped steel;

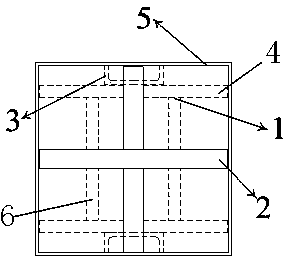

[0023] The double-web H-shaped steel can be a box-shaped body in which two H-shaped steels are butted through their notches.

[0024] The flange 4 of the double-web H-shaped steel and the middle parts of both ends of the two webs 6 are provided with symmetrical grooves respectively, and cross-shaped stiffeners 2 are welded in the grooves, such as Figure 7 As shown: the cross-shaped stiffener 2 is welded vertically by two flat plates 7 with grooves;

[0025] The inner wall of the sleeve 5 is provided with at least two pairs of channel steels 3 , each pair of channel steels is arranged with their backs facing each other, and their backs respectively press against both sides of the double-web H-shaped steel flanges.

[0026] like Figure 8 Shown: the buckling-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com