Clean steel box type profile steel buckling restrained brace

A buckling restraint, box-shaped technology, applied in building components, earthquake resistance, etc., can solve the problems of local buckling that cannot be used, prone to local buckling, and lack of core elements, and achieves flexible design, low cost, and reduced steel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

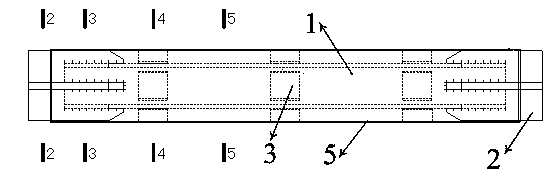

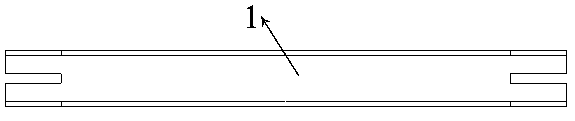

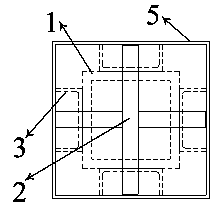

[0022] like Figure 1-Figure 7 Shown: a pure steel box-shaped steel buckling restraint support, which includes a box-shaped steel 1 and a sleeve 5 sleeved on the outside of the box-shaped steel; the box-shaped steel is a rectangular tube, in the middle of the four sides of its two ends Symmetrically open grooves respectively, and cross-shaped stiffeners 2 are welded in the grooves; such as Figure 8 Shown: The cross-shaped stiffening rib is formed by welding two flat plates 7 with grooves perpendicular to each other. Channel steels 3 are symmetrically arranged on the four surfaces of the inner wall of the sleeve 5, and each pair of channel steels is arranged in the back, and the backs of the channel steels are respectively pressed against each surface of the box-shaped steel.

[0023] like Figure 9 Shown: the pure steel box-shaped steel buckling restraint support is provided between the column 8 and the top beam 9 diagonally.

[0024] The four surfaces that make up the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com