Longitudinal horizontal movement method for super-long super-heavy bridge components

A technology for bridges and components, applied in the field of longitudinal translation of super-long and super-heavy bridge components, which can solve problems such as high design standards of track foundations, threats to the overall stability of steel truss girder longitudinal movement, and limited by site space, etc., to achieve the bearing capacity of track foundations The effect of low requirements, low requirements for the carrying capacity of a single device, and low investment in procurement and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

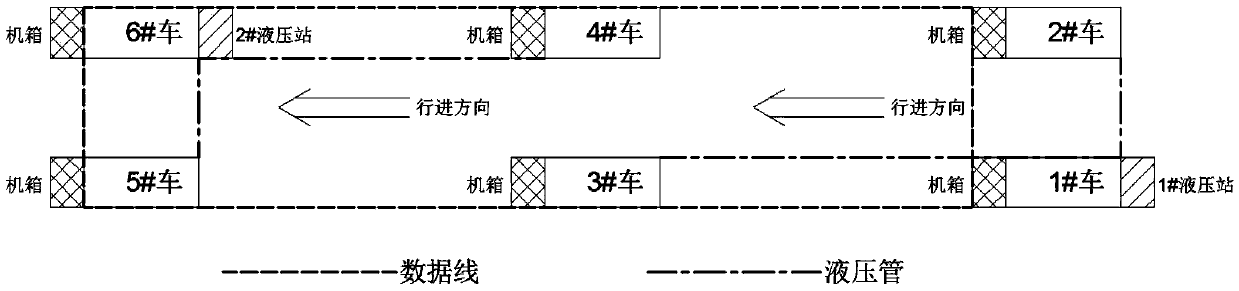

[0014] A method for longitudinal translation of super-long and super-heavy bridge components. Six track-type trolleys are arranged symmetrically at equal intervals below the lower chord nodes of the main truss on both sides of each steel truss girder, such as the 2# of the main truss on both sides of each steel truss girder , 5#, and 8# lower chord nodes are respectively symmetrically arranged with two rail trolleys. The six track-type trolleys move toward the direction of the bridge components first from left to right, followed by the first trolley 1#, the second trolley 2#, the third trolley 3#, the fourth trolley 4#, and the fifth trolley 5#, the sixth car 6#.

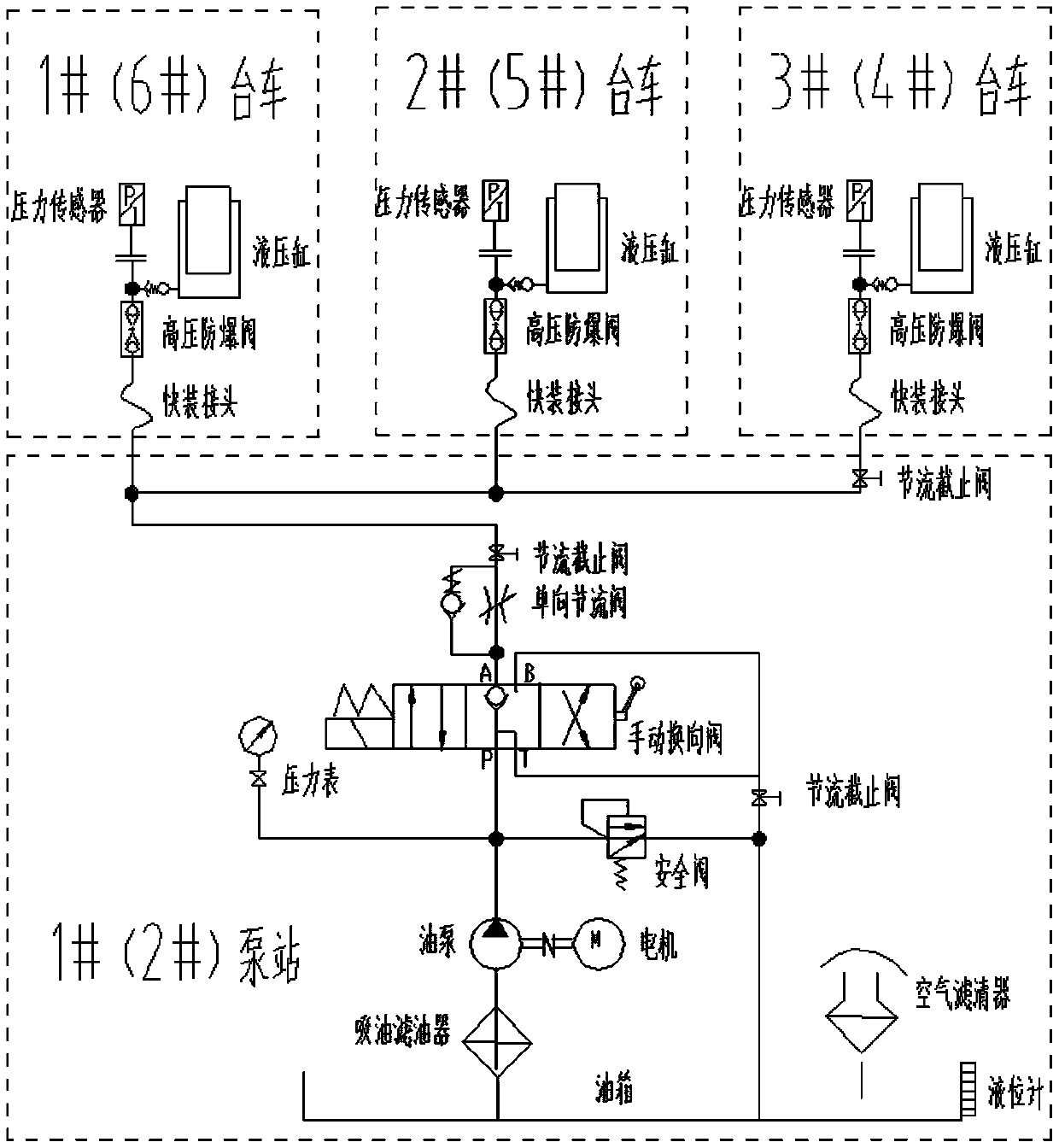

[0015] The six rail-mounted trolleys are controlled by two sets of hydraulic systems. This is because the long oil supply pipeline is not conducive to the simultaneous lifting of the rail-mounted trolleys, and it is difficult to maintain pressure balance.

[0016] Considering that the two sets of oil supply circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com