Method for alternately constructing underground vertical members using top-down construction method

A technology of vertical components and construction methods, applied in underwater structures, excavation, artificial islands, etc., can solve problems such as great influence on air quality, and achieve the effect of shortening the overall construction period, shortening the construction period, and not delaying the overall construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

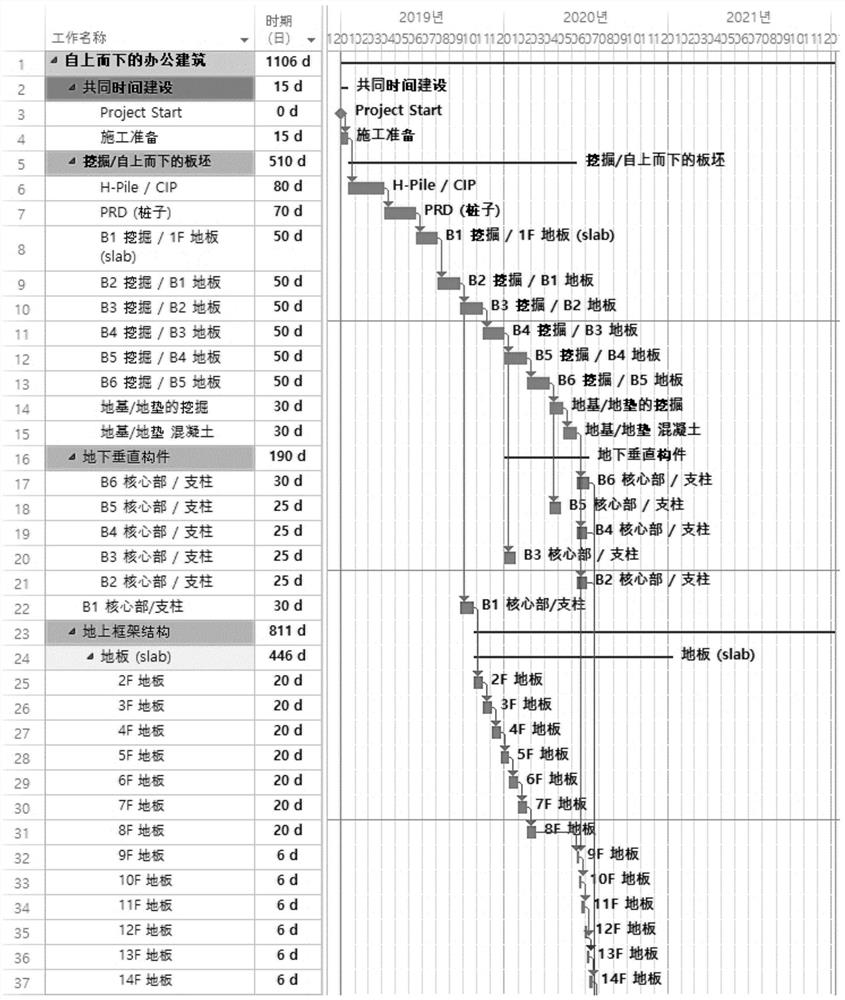

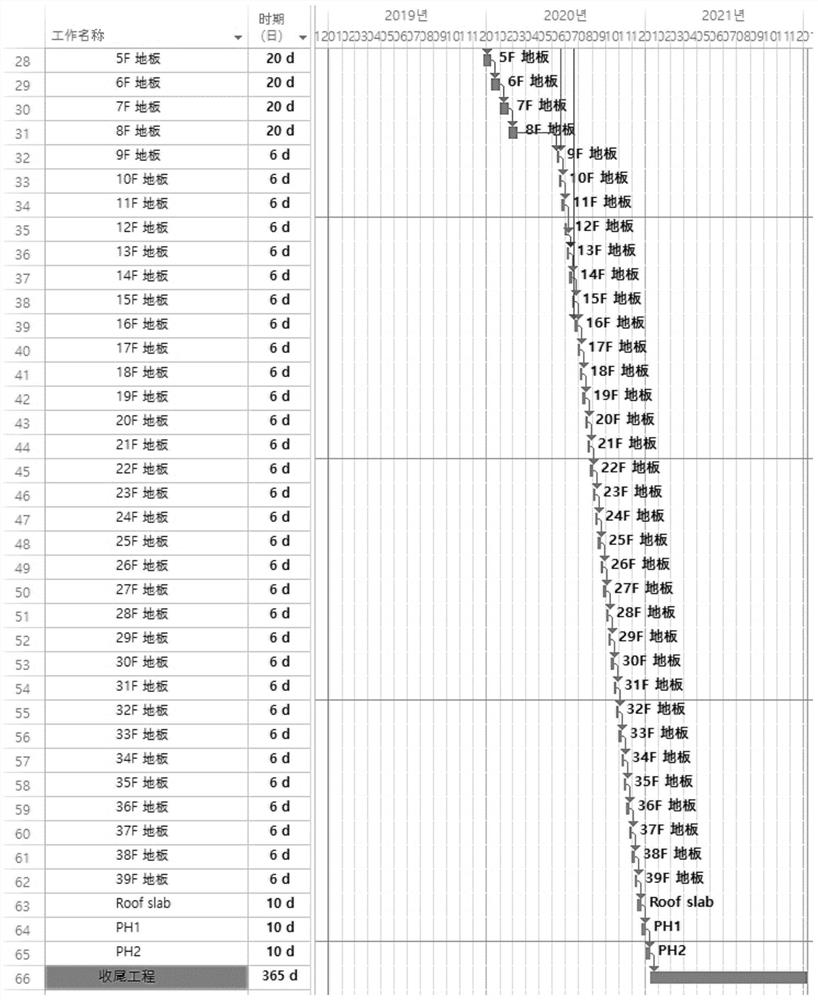

[0047] The construction method of every other underground vertical member constructed according to the reverse drilling method of the present invention will be described in detail below.

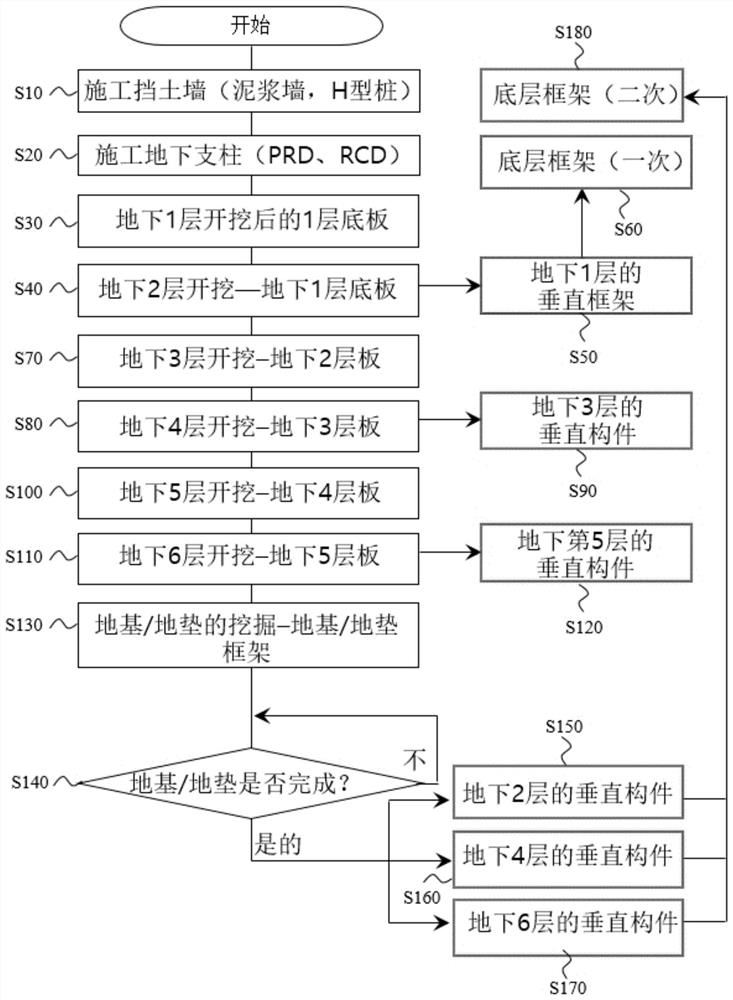

[0048] figure 1 It is a general flow chart of the construction method of the underground vertical member by the back-drilling method of every other construction according to an embodiment of the present invention. The target project is an SRC office building with 6 floors underground and 39 floors above ground.

[0049] see figure 1 , In the construction method of the underground vertical member of the present embodiment, in the retaining construction step S10, the retaining wall is constructed in the basement based on the outer wall of the basement floor of the building, and the mud walls, CIP, H piles are constructed. and ground plane.

[0050]In the underground pile construction step S20, the pillars of the building are constructed from the ground to the foundation and the floor mat by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com