Monolithic horizontal movement system of wagon drill

A vehicle-mounted drilling rig and translational system technology, which is applied to drilling equipment, earthwork drilling, drilling equipment and methods, etc., to achieve the effect of ensuring synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

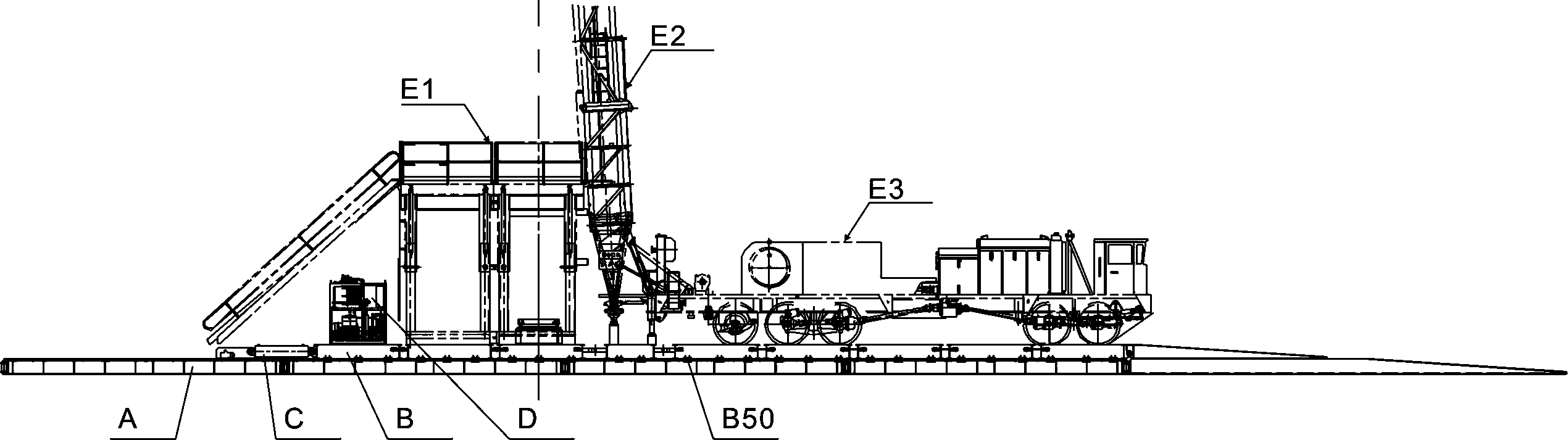

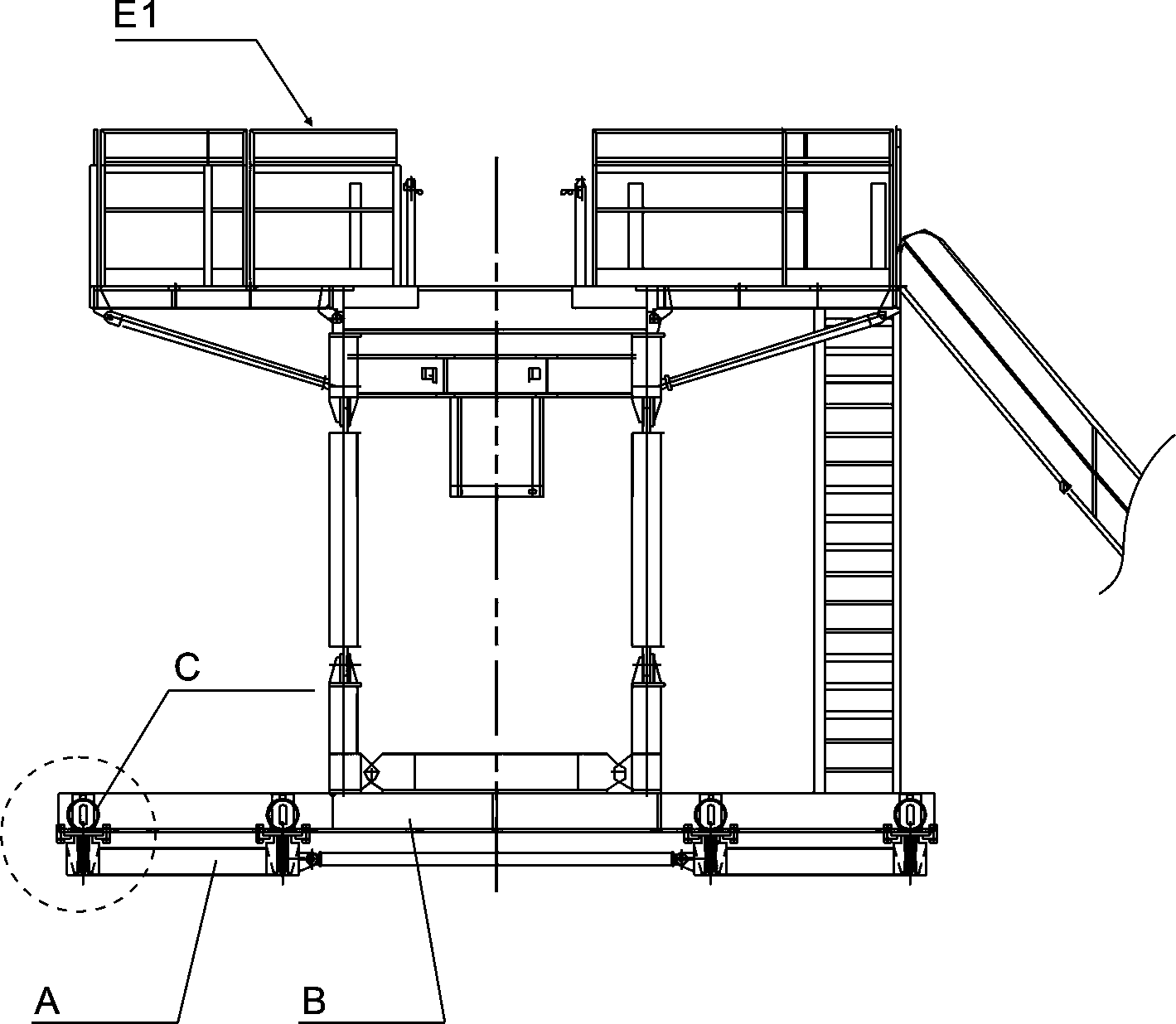

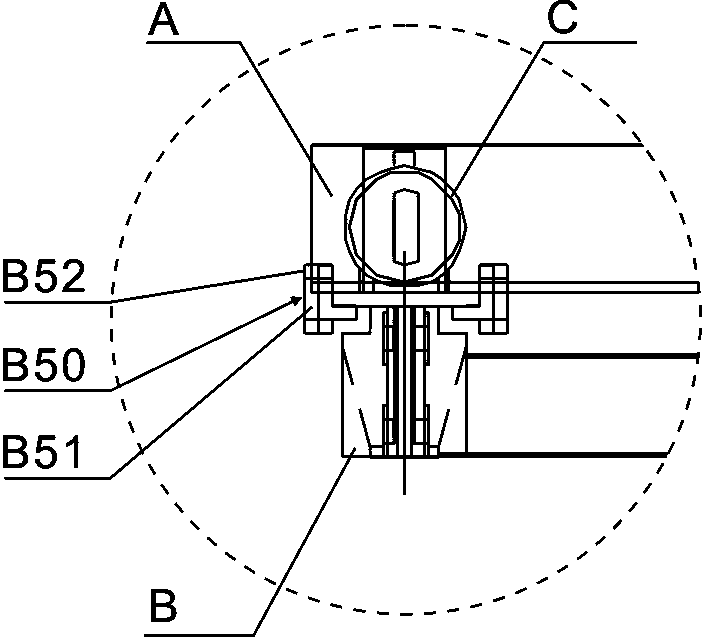

[0044] -Such as figure 1 , figure 2 and Figure 4 As shown, the overall translation system of the vehicle-mounted drilling rig includes: a lower guide rail A, an upper guide rail B, a moving mechanism C, and a hydraulic operating system D; the lower guide rail A is set on the ground, and the upper guide rail B is set on the lower guide rail A , slidingly fit with the lower guide rail A, the moving mechanism C is arranged on the front end and / or the rear end of the upper guide rail B, and is power-connected with the hydraulic operating system D, and the hydraulic operating system D is arranged on the upper guide rail B;

[0045] The lower guide rail A includes a plurality of lower guide rail racks A1 and lower boat-shaped bases A20 connected to each other as a whole, and the lower boat-shaped base A20 is arranged at the front end and / or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com