Displacement experiment fluid control method and displacement experiment device

A technology of displacement experiment and control method, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the adverse effects of in-depth research on the gas flooding oil miscible process, it is difficult to observe the gas flooding oil miscible process, Problems affecting the accuracy of experimental data, etc., to achieve real-time effective control, solve remote control problems, and eliminate adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

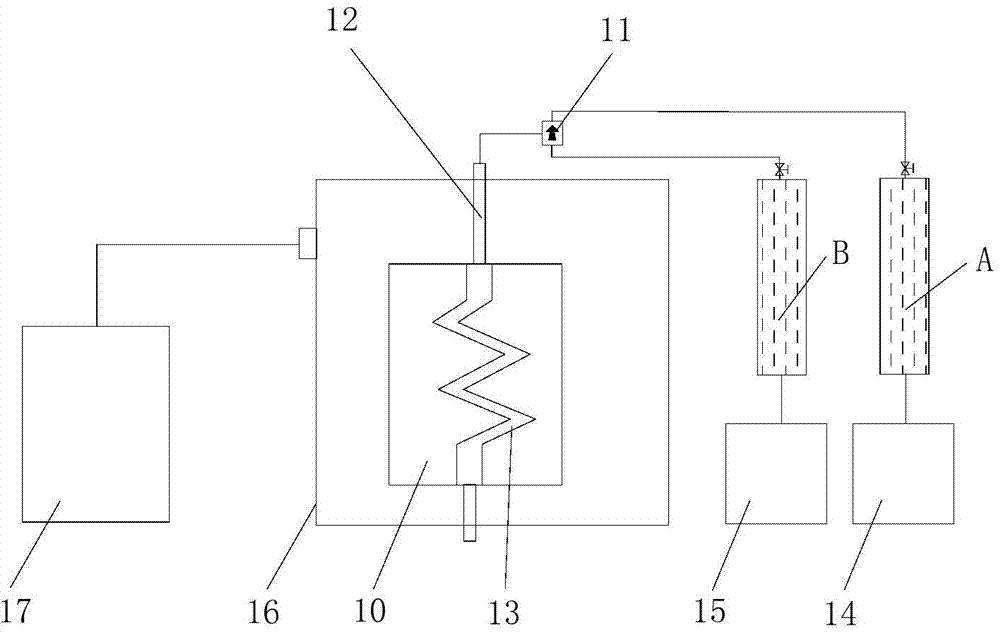

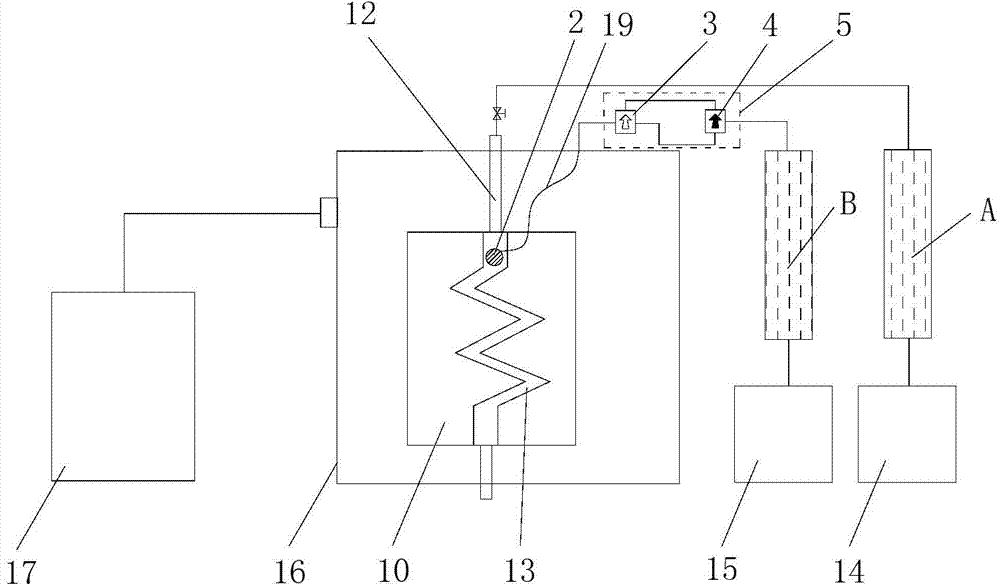

[0056] The invention proposes a fluid control method for a displacement experiment, comprising: injecting a saturated fluid into the channel of the inner model through an inlet connection pipe connected to the inner model of the displacement experiment device, and stopping the injection of the saturated fluid after the saturated fluid step is completed; The displacement fluid is directly injected into the pores of the inner model through a pipeline directly connected with the inner model to perform the displacement step.

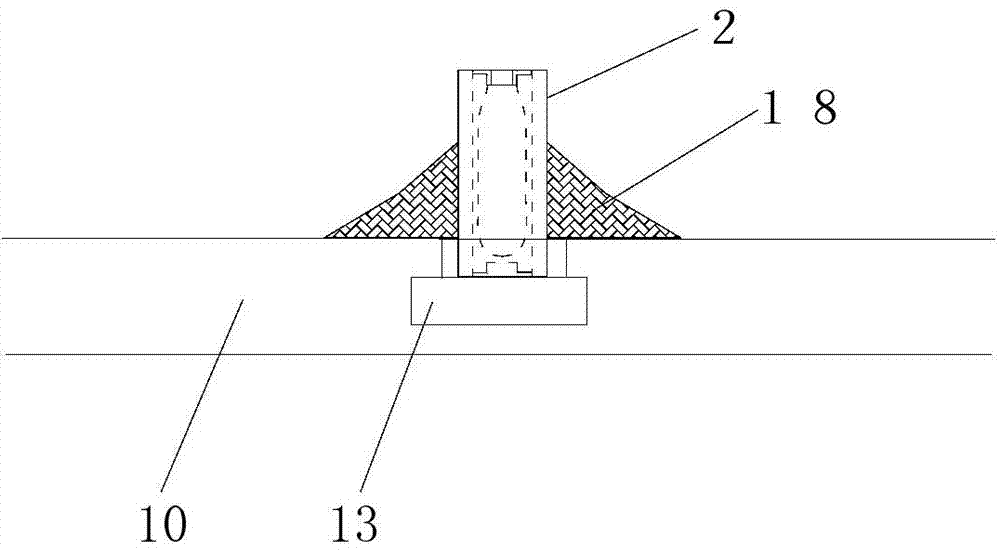

[0057] The method of the present invention installs a fluid switch on the inner mold channel close to the inlet connecting pipe, and makes the fluid switch be arranged in the outer mold outside the inner mold, and controls the opening or closing of the fluid switch by a control device arranged outside the outer mold. Closed to realize the control of injecting or stopping injecting displacement fluid into the channel.

[0058] The displacement experimental de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com