Small air pillow pressurization system

A technology of supercharging system and small air pillow, applied in jet propulsion device, rocket engine device, machine/engine, etc., can solve problems such as affecting engine work, early shutdown, air pillow pressure attenuation, etc., to avoid single point failure, guarantee The effect of smooth startup and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

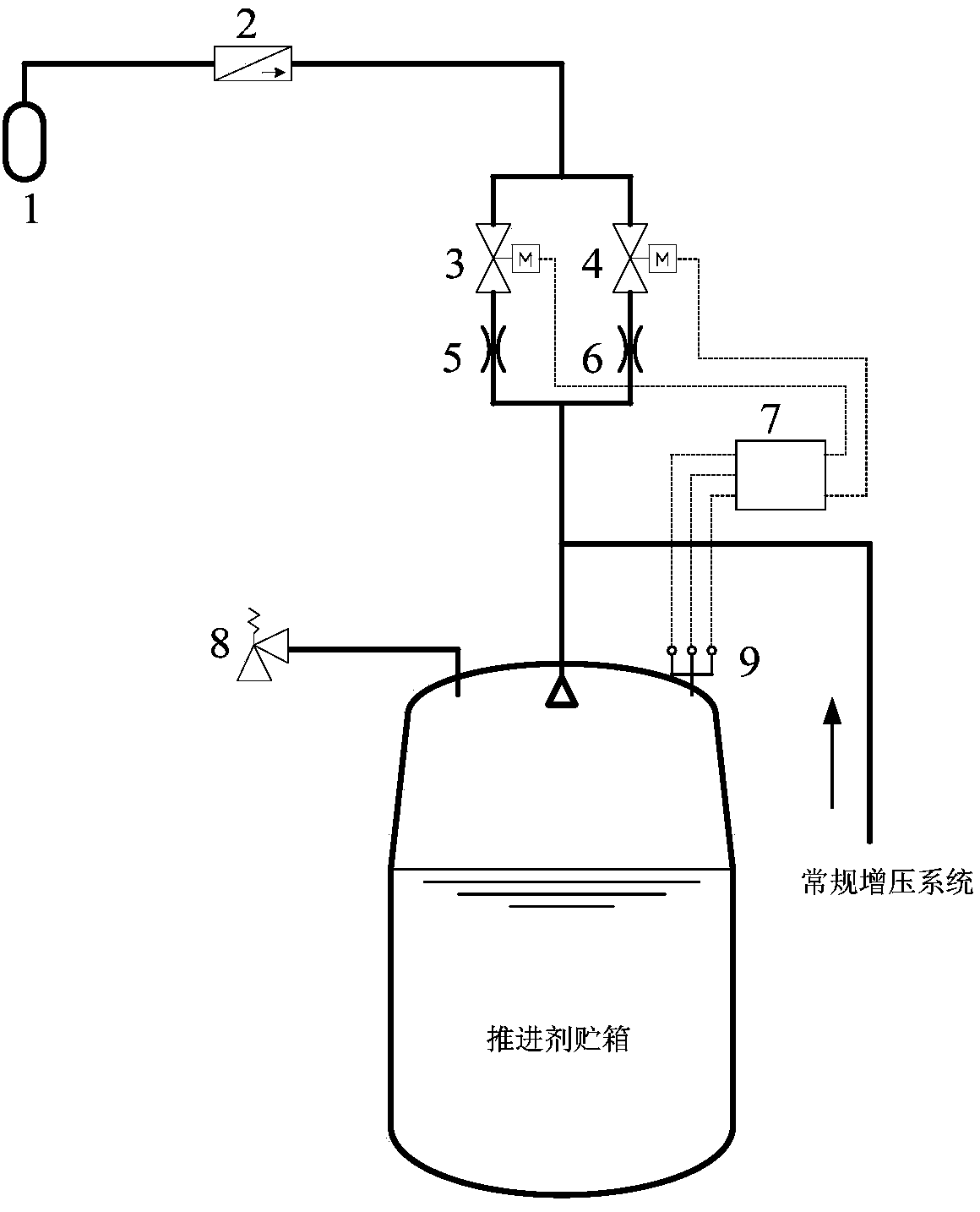

[0008] Such as figure 1 As described, the present invention consists of an emergency booster cylinder 1, a filter 2, a main booster solenoid valve 3, an auxiliary booster solenoid valve 4, a main booster orifice 5, an auxiliary booster orifice 6, and a booster controller 7 , safety valve 8 and pressure sensor 9, the main booster solenoid valve 3 is connected in series with the main booster orifice 5 to form the main booster control channel, and the auxiliary booster solenoid valve 4 is connected in series with the auxiliary booster orifice 6 to form the auxiliary booster control channel, the main booster control channel is connected in parallel with the auxiliary booster control channel, wherein the main booster orifice plate 5 and the auxiliary booster orifice plate 6 are connected to the top of the propellant tank, and the main booster solenoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com