Bolt for mixing machine

A mixing machine and bolt technology, applied in the direction of screws, mechanical equipment, threaded fasteners, etc., can solve the problems of bolt thread wear, bolt shaking, affecting the working performance and stability of the mixing machine, etc., to increase the working performance and stability. Stability, the effect of avoiding thread wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described below in conjunction with accompanying drawing.

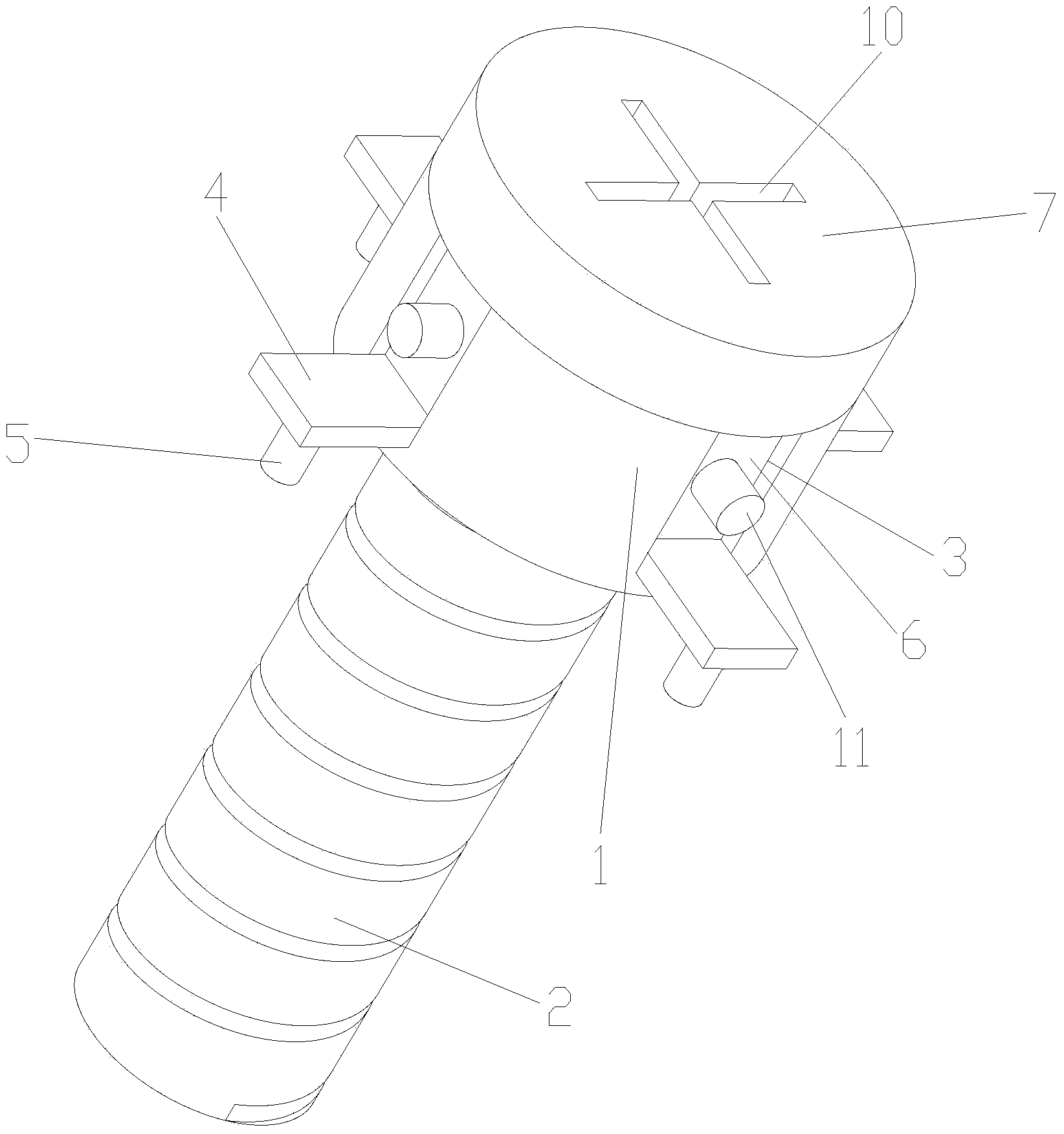

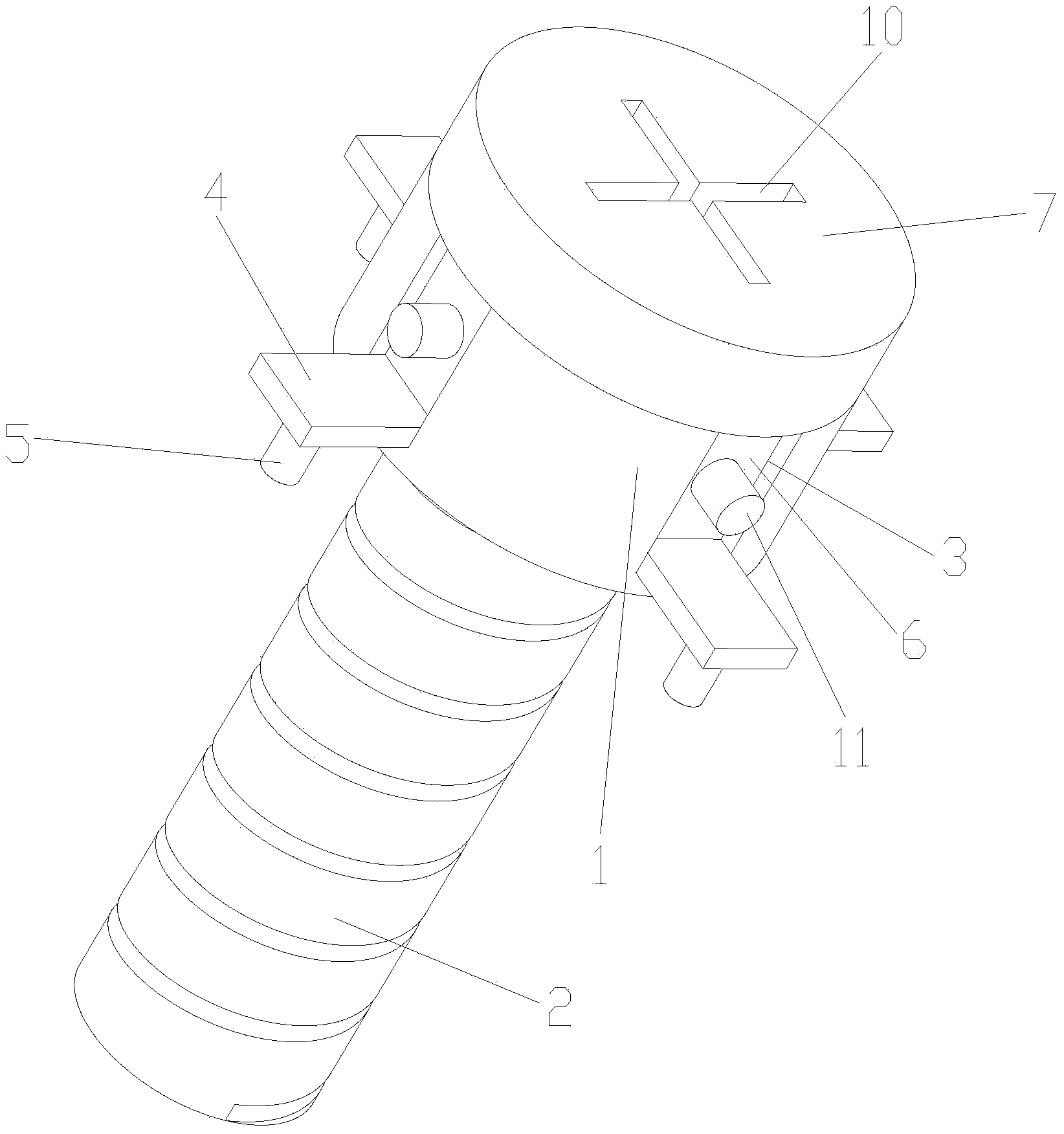

[0018] as attached figure 1 , 2 The shown bolt for a mixer according to the present invention includes a bolt head 1 and a screw rod 2, the bolt head 1 and the screw rod 2 are connected as a whole, and the upper surface of the bolt head 1 has at least two annular arrays. a fixed slot 3; the fixed slot 3 communicates with the outside; the fixed slot 3 is provided with a fixed block 4; one end of the fixed block 4 stretches out the bolt head 1; the fixed block 4 stretches out the bolt head 1 The lower surface of the part is provided with a fixed column 5; the fixed groove 3 is also provided with a clamping block 6 above the fixed block 4; the upper surface of the clamped block 6 is flush with the upper surface of the bolt head 1; the bolt The upper surface of the head 1 is also provided with a stopper 7; the lower surface area of the stopper 7 is greater than or equal to the upper sur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap