Inspection apparatus

A technology for inspecting devices and images, applied in photovoltaic power generation, optical testing for flaws/defects, etc., to achieve high-precision defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

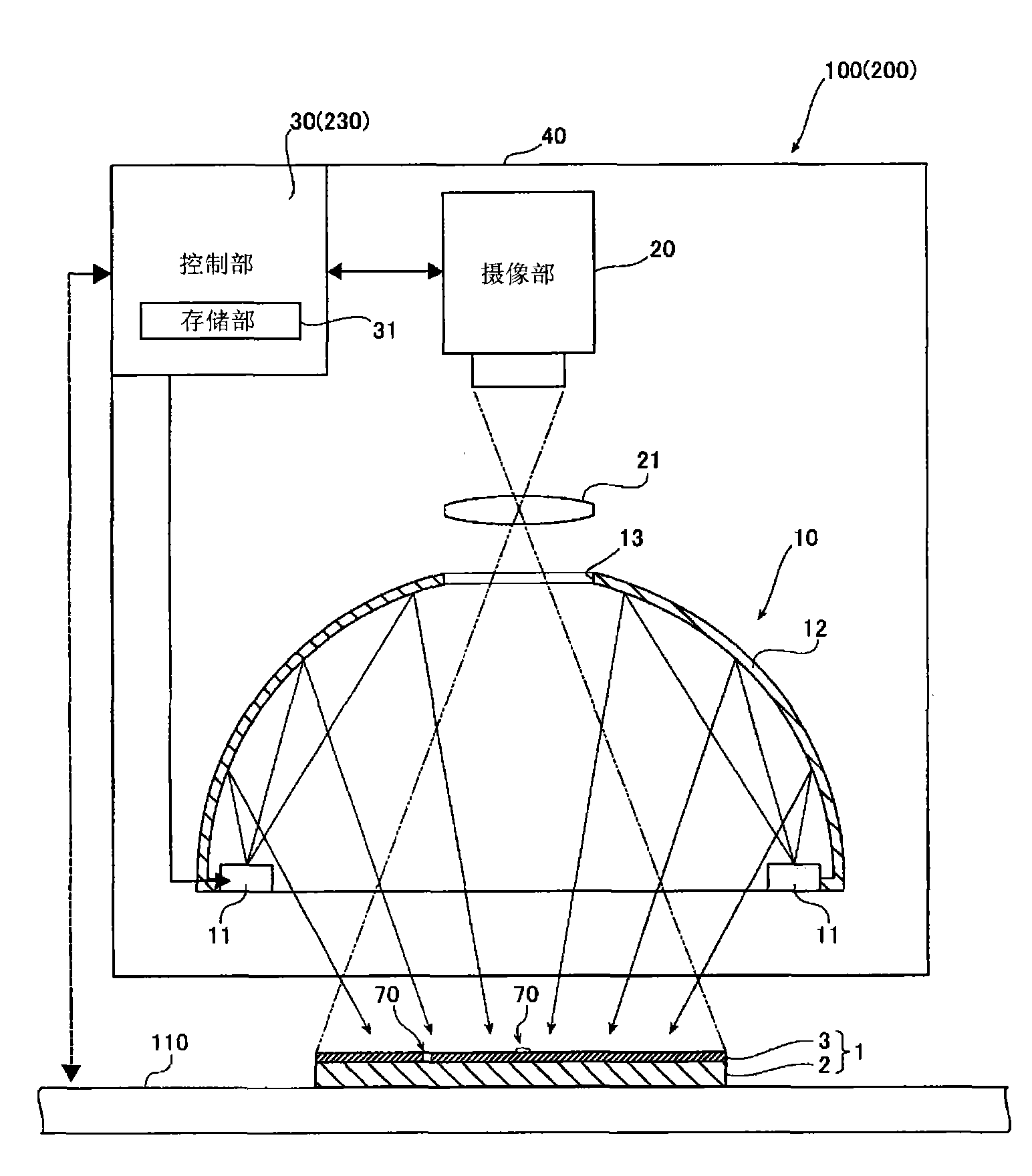

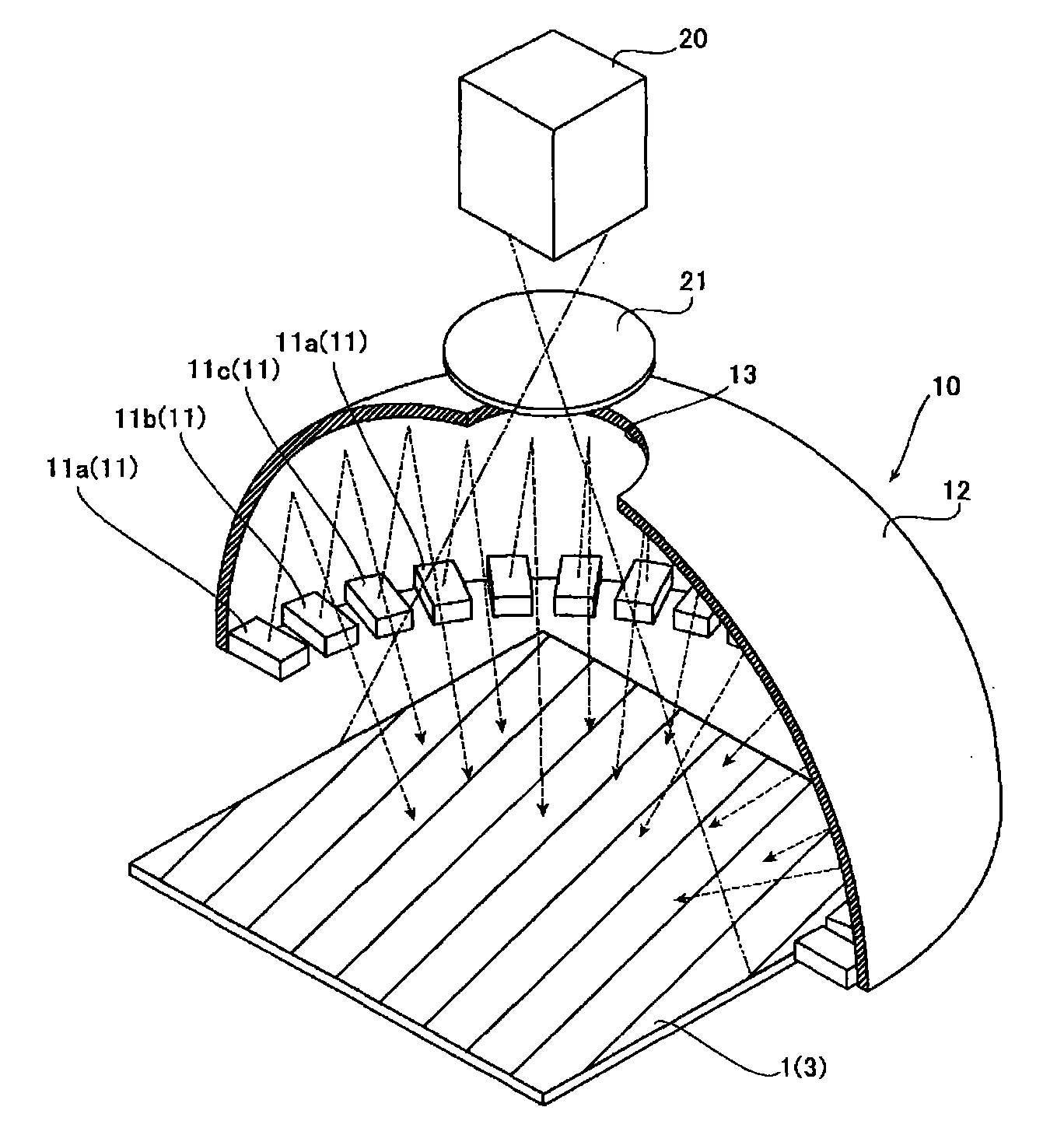

[0067] First, refer to figure 1 The overall configuration of the visual inspection apparatus 100 according to the first embodiment of the present invention will be described. In the first embodiment, an example in which the present invention is applied to the appearance inspection apparatus 100 that inspects defects of the anti-reflection film formed on the surface of the solar battery cell (surface defect of the solar battery cell) is described.

[0068] The appearance inspection device 100 of the first embodiment is an inspection device that is installed on a production line in the production step of the solar cell unit 1 and performs an in-line inspection. The solar battery cell 1 includes a semiconductor substrate 2 (hereinafter referred to as a substrate 2); and an anti-reflection film 3 formed on the surface (light-receiving surface) of the substrate 2. In addition, figure 1 Here, for convenience, the thickness of the solar cell 1 is enlarged to schematically show each laye...

no. 2 Embodiment approach

[0110] Secondly, refer to figure 1 , Figure 6(a), Figure 6(b)~Figure 9 The appearance inspection apparatus 200 of the second embodiment of the present invention will be described. In the second embodiment, an example of a configuration in which, in addition to the configuration of the first embodiment described above, a defect inspection is performed for each partial image of the captured image will be described. In addition, in the second embodiment, the device configuration is the same as that of the appearance inspection device 100 of the above-mentioned first embodiment, so the description is omitted. In addition, the appearance inspection apparatus 200 is an example of the "inspection apparatus" of the present invention.

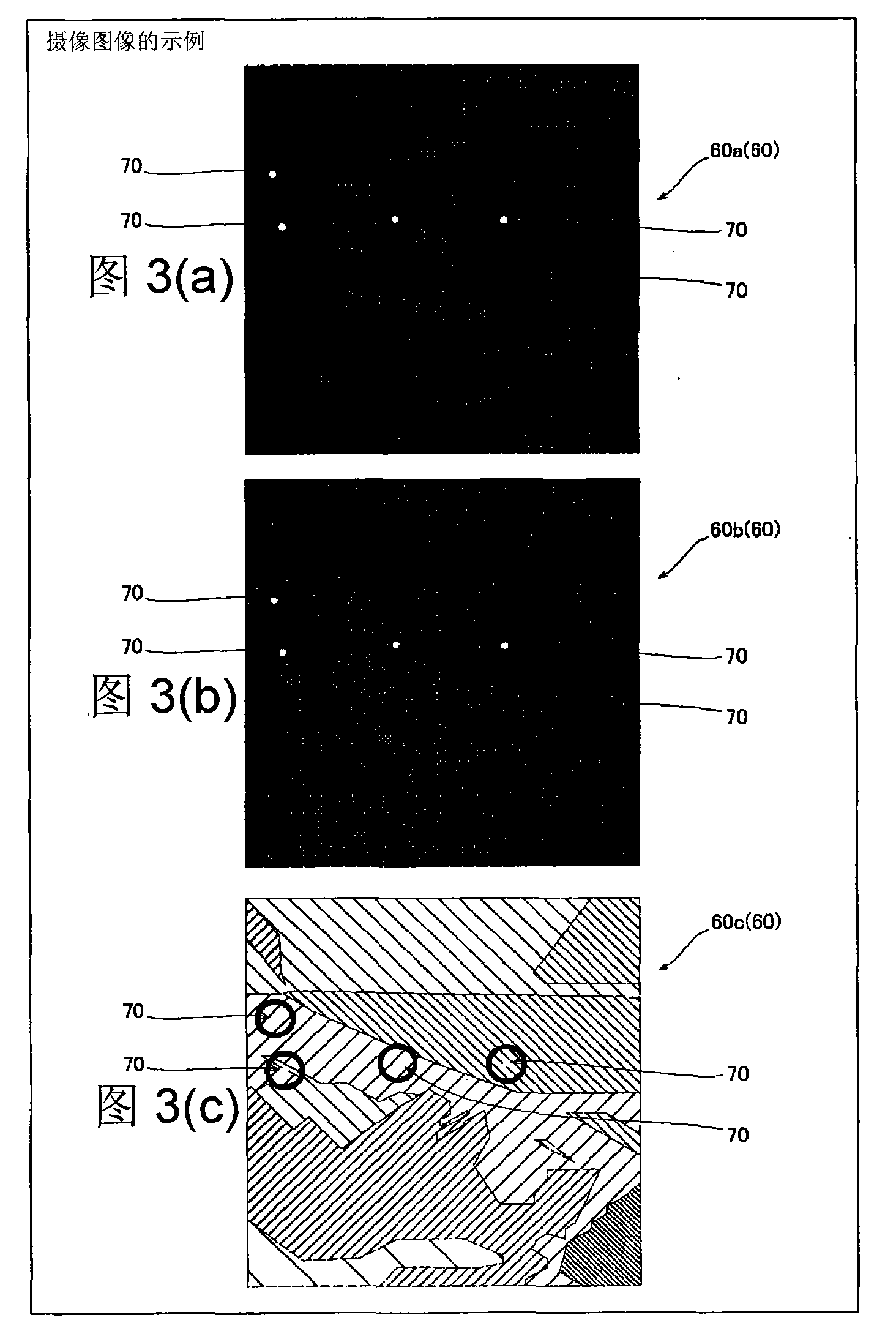

[0111] Such as Figure 8 As shown, the appearance inspection apparatus 200 of the second embodiment (refer to figure 1 ) Of the control unit 230 (refer to figure 1 ), the part images 80 of various illumination colors are respectively obtained for a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com