Deviation rectifying method for moving head lamp effect disc

A technology of effect disk and moving head light, applied in instruments, computer control, simulators, etc., can solve problems such as difficult work, inability to align the Hall plate with the magnet, errors, etc., and achieve the effect of fast and convenient deviation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings of the description.

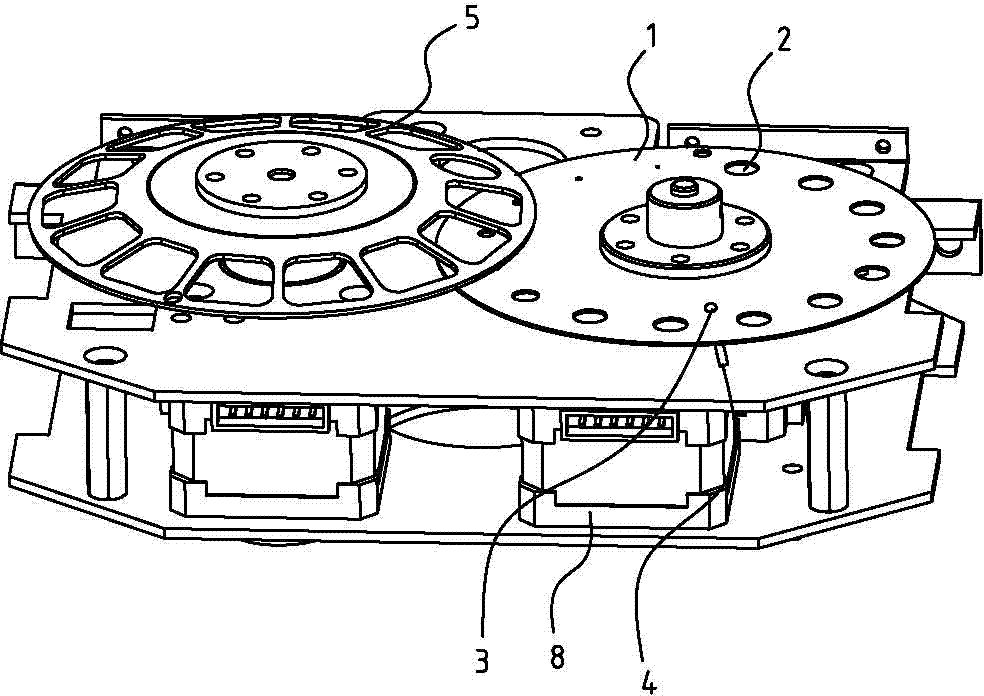

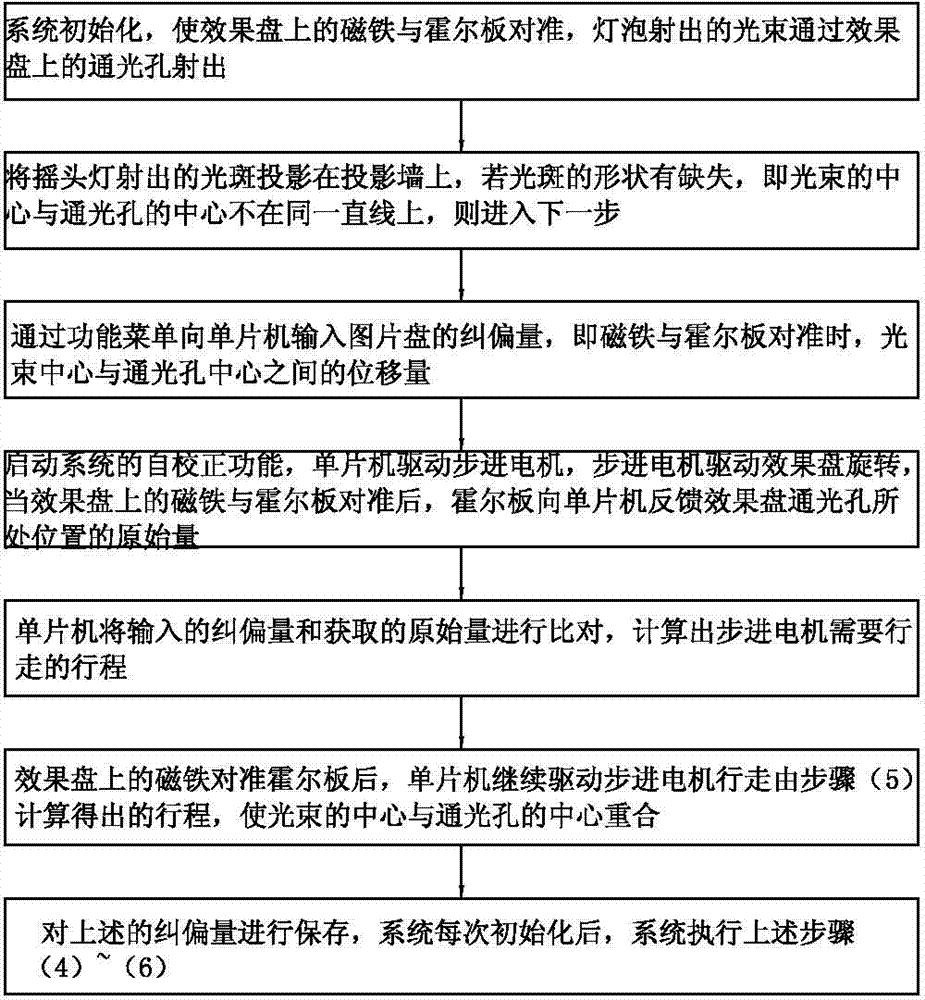

[0026] Such as figure 1 , 2 As shown, a method for correcting the deviation of the pattern wheel of the moving head light includes the following steps:

[0027] (1) System initialization, align the magnet 3 on the pattern plate 1 with the Hall plate 4, and the light beam 7 emitted by the bulb is emitted through the light hole 2 on the pattern plate 1;

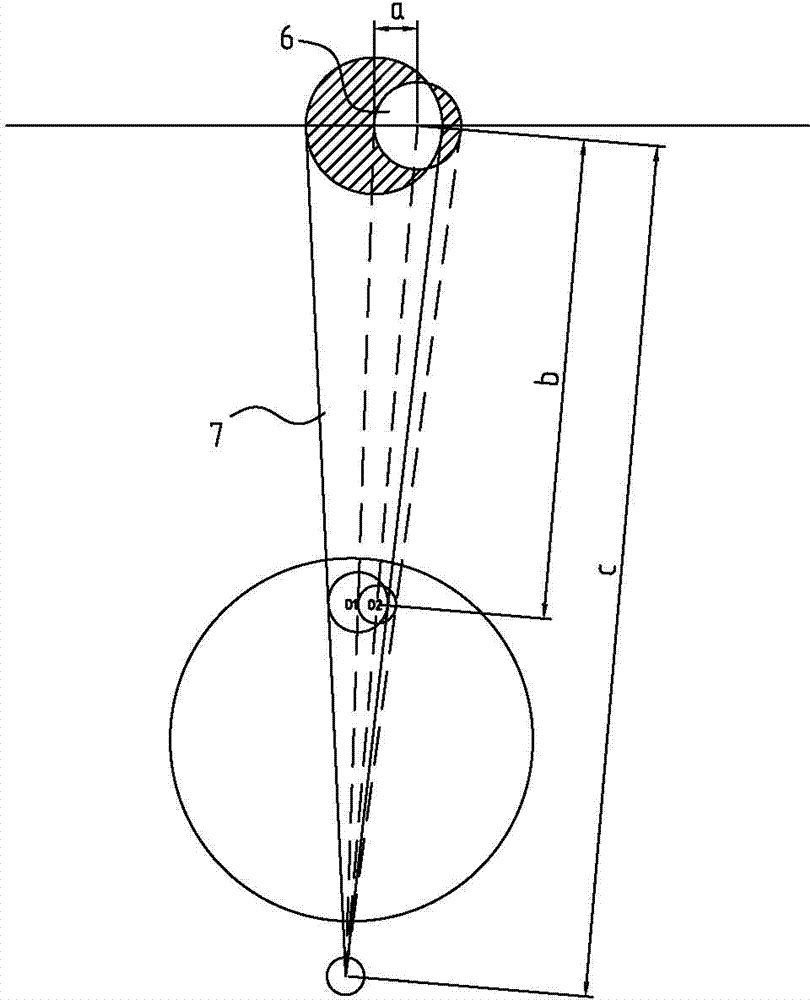

[0028] (2) if image 3 As mentioned above, project the light spot emitted by the moving head light on the projection wall, if the shape of the light spot is missing, that is, the center O1 of the beam 7 and the center O2 of the light hole 2 are not on the same straight line, then go to the next step;

[0029] (3) Input the deviation correction amount of the picture disk to the single chip microcomputer through the function menu, that is, the displacement amount between the center of the beam 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com