Designing method for supersonic velocity thrust exhaust nozzle considering inlet parameter unevenness

A technology of imported parameters and thrust nozzles, which is applied in calculation, electrical digital data processing, special data processing applications, etc., to achieve the effect of good thrust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

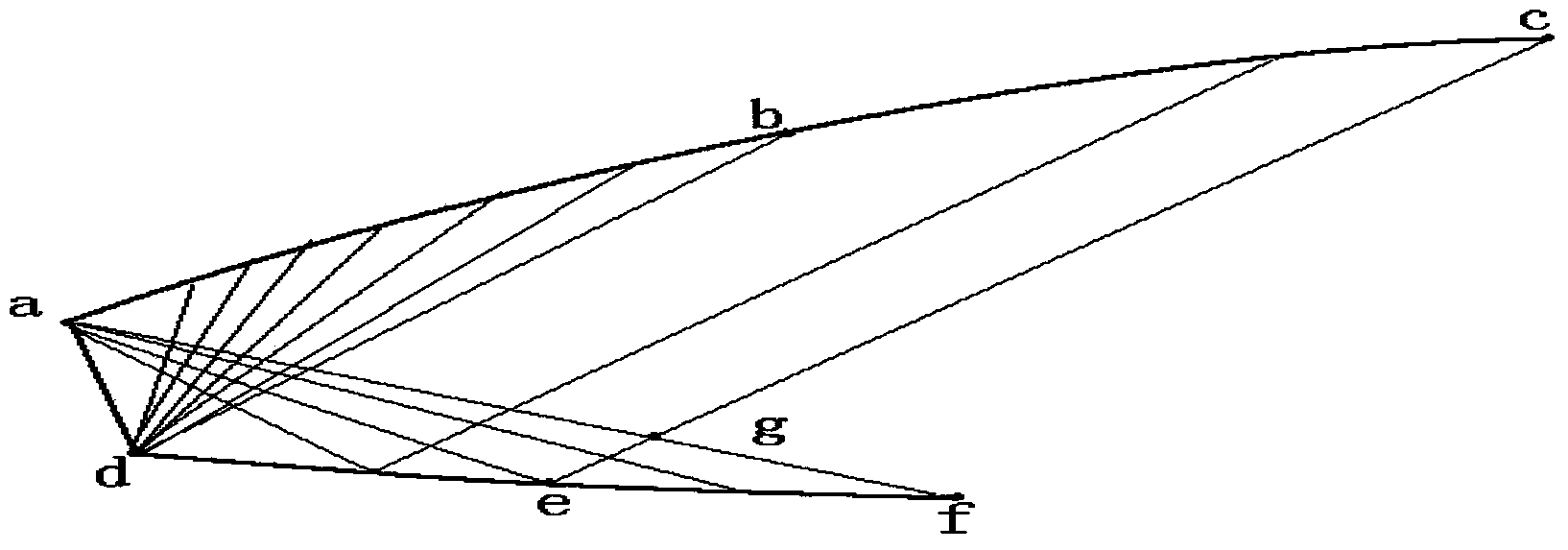

[0042] The nozzle area ratio is 4.69, the ratio of the length of the upper expansion surface to the throat height is 10.58, and the ratio of the length of the lower wall to the throat height is 3.7. Figure 5 Its import Mach number distribution curve. In the case of a nozzle drop pressure ratio of 60, the thrust of the nozzle obtained by this design method is 2.8% higher than that obtained by the conventional method.

Embodiment 2

[0044] The area ratio of the nozzle is 2.58, the ratio of the length of the upper expansion surface to the height of the throat is 7.7, the ratio of the length of the lower wall to the height of the throat is 4, and the attached Figure 6 Its import Mach number distribution curve, attached Figure 7 Its inlet total temperature distribution curve. In the case of a nozzle drop pressure ratio of 50, the thrust of the nozzle obtained by this design method is 1% higher than that obtained by the conventional method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com