Mini-type anti-explosion fireproof capacitor

A capacitor and miniature technology, applied in the direction of capacitors, electrical components, etc., can solve the problems of capacitor explosion, packaging materials without mechanical strength, and difficulty in setting up explosion-proof structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

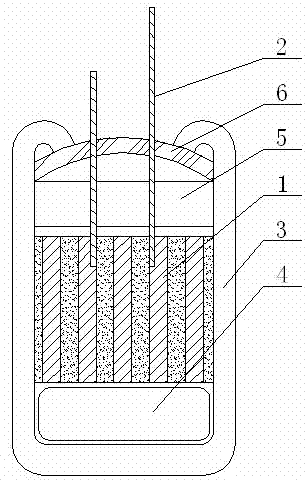

Embodiment 1

[0020] A miniature explosion-proof and fire-proof capacitor according to the present invention includes: a film core 1, a lead-out terminal 2, and a casing 3 wrapping the film core 1 and the lead-out terminal 2, and a fireproof bag 4 is also arranged inside the casing 3 , the fireproof bag 4 is filled with a fire extinguishing agent. Further, the shell 3 includes a bottom wall 31 and a mouth 32, the fireproof package 4 is located between the film core 1 and the bottom wall 31 of the shell 3, the mouth 32 of the shell 3 is located in the Above the film core 1. Further, it also includes a fixing seat 5 for fixing the lead-out terminal 2 , the fixing seat 5 is fixed in the casing 3 and located above the film core 1 . Further, a reinforced cover 6 is included, the reinforced cover 6 is located in the housing 3 and above the fixing seat 5, the reinforced cover 6 is spherically arched; the housing 3 also includes a side wall 33, A curling edge 34 is disposed on the top of the side...

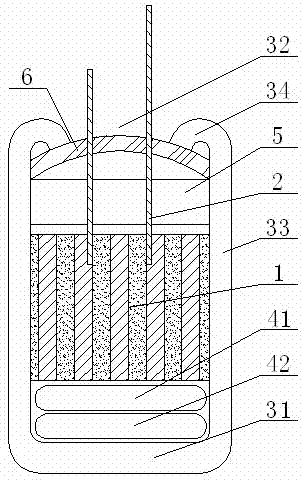

Embodiment 2

[0022] The film core 1, the lead-out terminals 2, and the shell 3 wrapping the film core 1 and the lead-out terminals 2, the shell 3 is also provided with a fireproof bag 4, and the fireproof bag 4 is filled with a fire extinguishing agent. Further, the shell 3 includes a bottom wall 31 and a mouth 32, the fireproof package 4 is located between the film core 1 and the bottom wall 31 of the shell 3, the mouth 32 of the shell 3 is located in the Above the film core 1. Further, it also includes a fixing seat 5 for fixing the lead-out terminal 2 , the fixing seat 5 is fixed in the casing 3 and located above the film core 1 . Further, a reinforced cover 6 is included, the reinforced cover 6 is located in the housing 3 and above the fixing seat 5, the reinforced cover 6 is spherically arched; the housing 3 also includes a side wall 33, A curling edge 34 is disposed on the top of the side wall 33 , and the curling edge 34 is located above the reinforcing cover 6 . Specifically, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com