Method for manufacturing composite glass silicon substrate and adapter plate capable of regulating and controlling large pressure

A composite glass and manufacturing method technology, which is applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problem that small-sized reflow glass cannot be processed, substrates and adapter plates take a long time to manufacture, and small spacing cannot be achieved. Problems such as components, to achieve the effect of shortening processing time, reducing equipment requirements, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

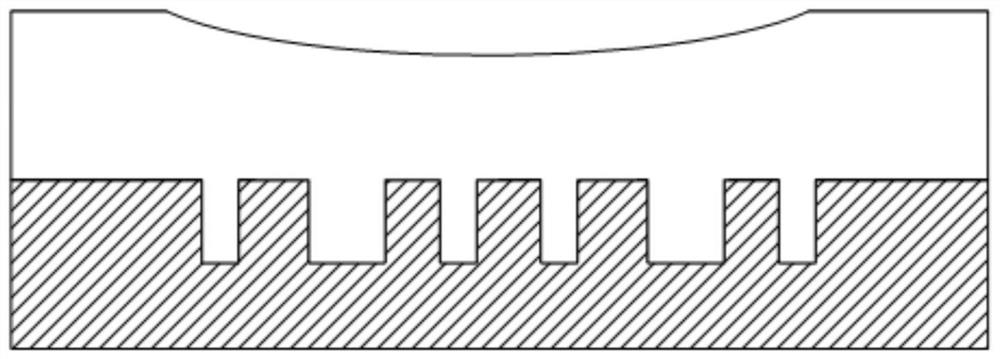

[0053] Figure 2- Figure 8 A high-efficiency composite glass-silicon substrate and adapter plate manufacturing technology based on adjustable large pressure is shown, including:

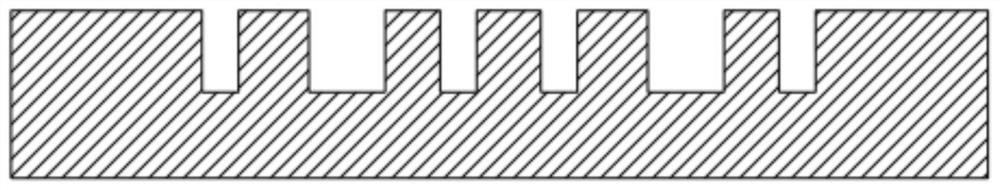

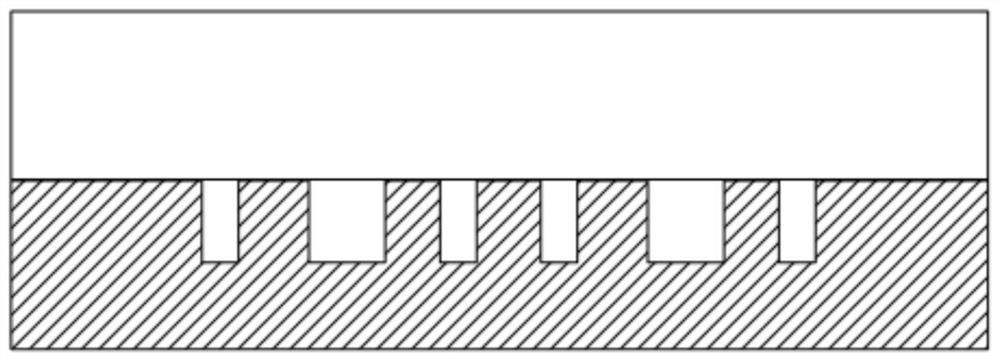

[0054] Step 1, as shown in FIG. 2 , a mold cavity 20 with a micro-component structure 22 is processed on the first substrate wafer 10 . The mold cavity 20 may be processed by deep reactive ion etching (DRIE) or anisotropic wet etching. The processing of the mold cavity 20 can also be performed by combining laser processing with wet etching, dry etching and wet etching, micro-EDM and wet etching, micro-ultrasonic One of the realizations in the method of combining processing and wet etching. The first substrate wafer 10 is a silicon wafer. The thickness of the silicon wafer can be 300um, 500um, 800um, 1mm, 2mm or more, and the diameter of the silicon wafer can be 2 inches, 4 inches, 6 inches, 8 inches, 12 inches. As an example, 6 inches and 1mm thickness are selected. of silicon wafers. The openin...

Embodiment 2

[0061] Figure 2- Figure 8 A high-efficiency composite glass-silicon substrate and adapter plate manufacturing technology based on adjustable large pressure is shown, including:

[0062] Step 1, as shown in FIG. 2 , a mold cavity 20 with a micro-component structure 22 is processed on the first substrate wafer 10 . The mold cavity 20 may be processed by deep reactive ion etching (DRIE) or anisotropic wet etching. The processing of the microstructure mold cavity 20 can also be carried out by combining laser processing with wet etching, combining dry etching with wet etching, combining micro-EDM with wet etching, A realization of the combination of micro-ultrasonic machining and wet etching. The first substrate wafer 10 is a silicon wafer. As an example, an 8-inch 2mm-thick silicon wafer is selected, and an array of mold cavities 20 with openings of 1um, 5um, 10um, and 50um are processed on the silicon wafer. The depth of the mold cavity 20 is about 200um.

[0063] Step 2, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com