Short arc type discharge lamp

A discharge lamp and arc light technology, applied in the direction of discharge lamps, gas discharge lamps, high-pressure discharge lamps, etc., can solve the problems of lamp breakage, breakage, and inability to prevent breakage flexibly relative to the lamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

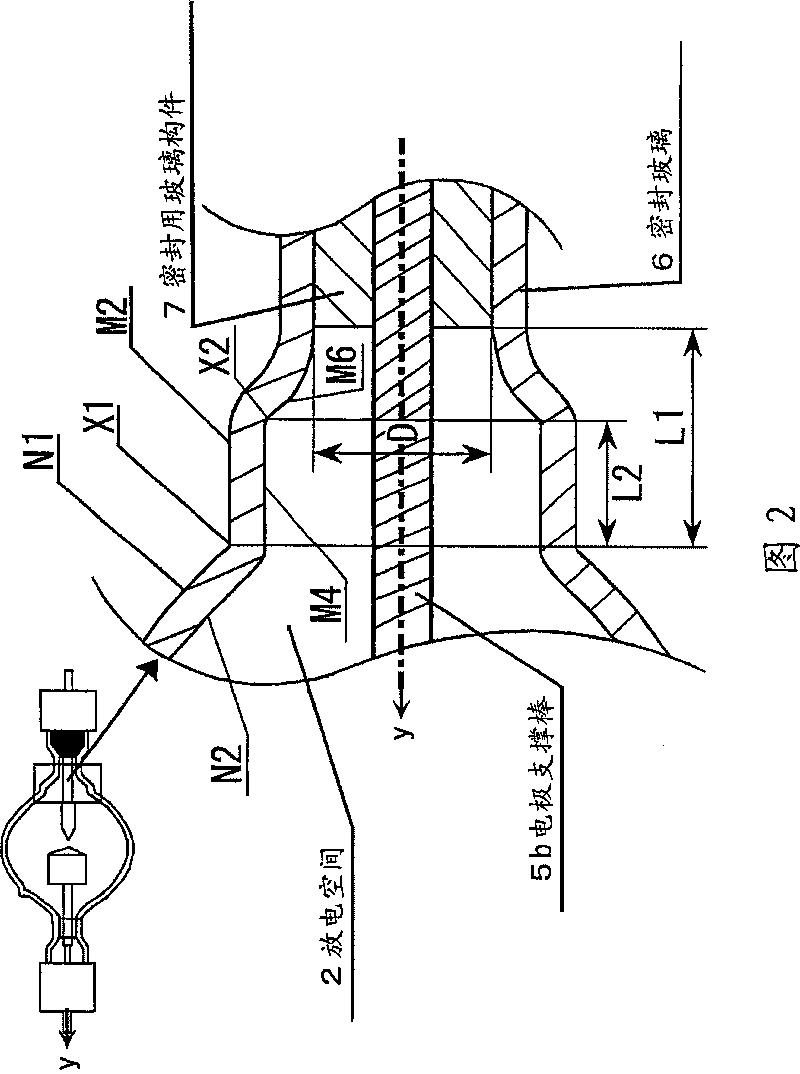

[0029] An embodiment of the present invention is a short-arc type discharge lamp with an internal pressure of 2.0 to 3.0 MPa when it is lit. The dimension from the end of the spherical surface of the luminous tube to the front end of the sealing part is set as L1 (mm), and The diameter of the sealing glass member is set to D (mm), and when the internal pressure of the lamp is set to P (MPa), the relationship D<(-0.38×P+1.79)×L1+(-3.32×P+24.3 ), in the range L2 from the spherical end X1 of the arc tube to the intersection point X2 of two different curvatures on the inner surface of the lamp, the thickness t of the sealing glass is 3.0mm≦t≦5.0mm.

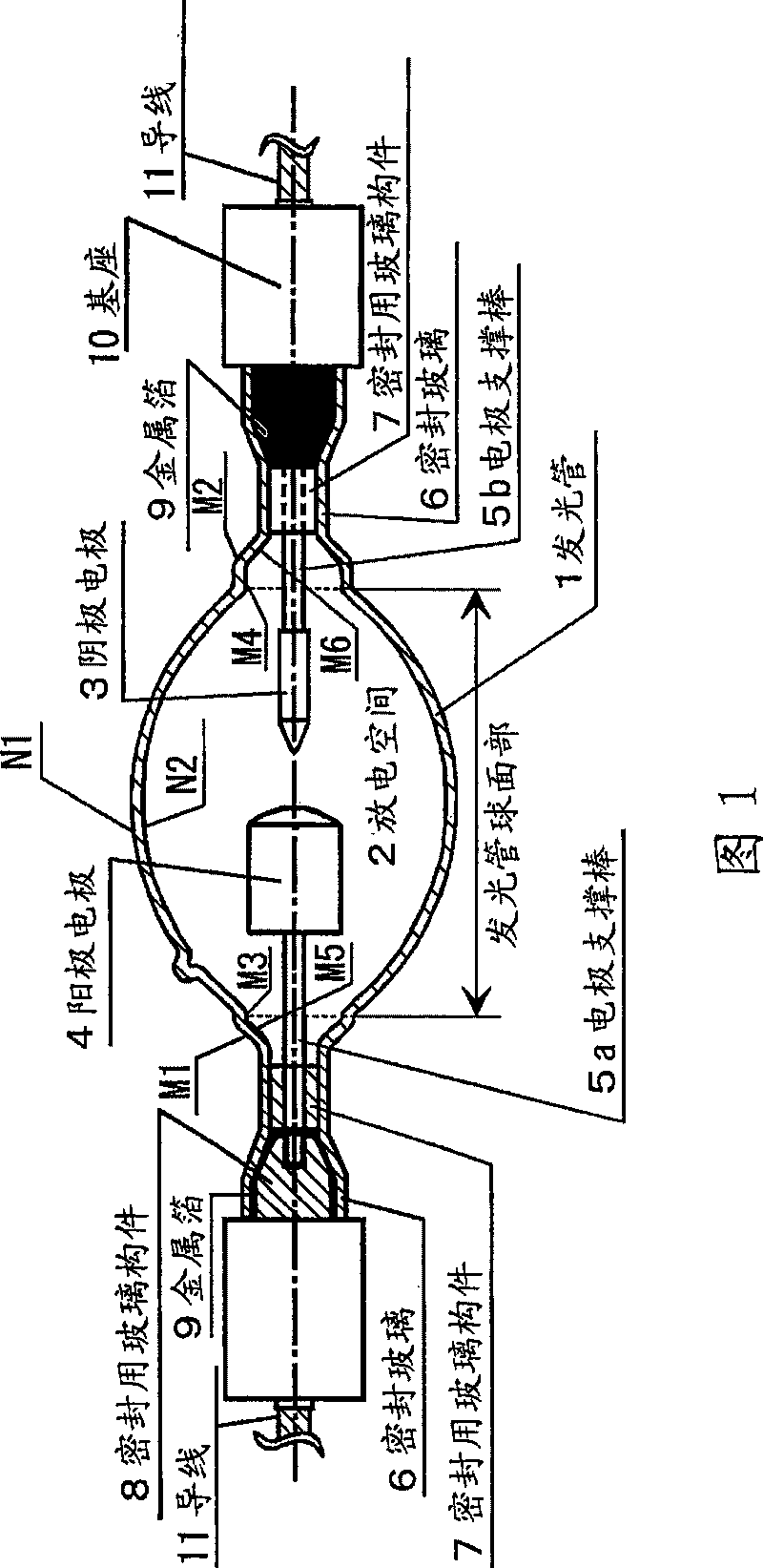

[0030] figure 1 It is a conceptual diagram of a short-arc type discharge lamp in an embodiment of the present invention. figure 2 It is a partially enlarged schematic diagram of the cathode electrode side of a short-arc discharge lamp. exist figure 1 and figure 2Among them, the luminous tube 1 is a glass bulb of a short-arc di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com