Method for etching single side of glass panel

A glass panel, single-sided technology, applied in the field of single-sided etching of glass panels, can solve the problems of poor glass edge effect and damage, and achieve the effect of easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

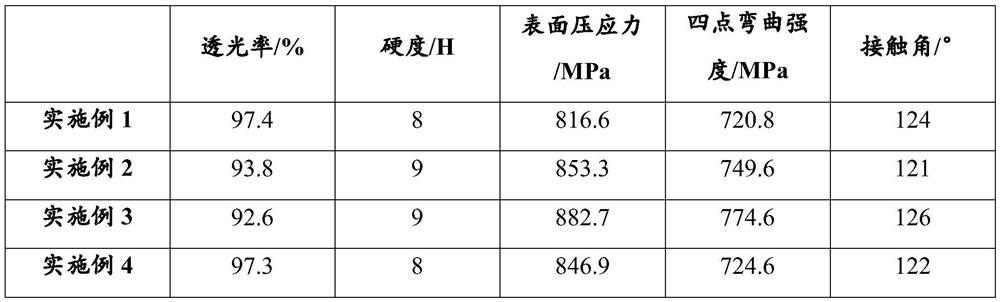

Examples

Embodiment 1

[0024] A method for one-sided etching of a glass panel of the present invention comprises the following steps:

[0025] Step 1: Select a glass panel with a thickness of 0.3mm and wash it at 25°C for 7 minutes, then dry it naturally for later use;

[0026] Step 2: Cover the non-etching surface of the glass panel cleaned in step 1 with a layer of protective paper first, then cover the protective paper with a layer of film, the film completely covers the protective paper, and finally cover the back The board is adhered to the film with an acid-resistant tape;

[0027] Step 3: Lift the glass panel treated in step 2 with a rail for glass etching, hang it in the air, and then perform etching treatment on its etched surface;

[0028] Step 4: Carry out film removal treatment to the etched glass panel;

[0029] Step 5: Clean the glass panel after stripping.

[0030] Wherein, the cleaning solution in step 1 of the method for etching a single side of a glass panel of the present inven...

Embodiment 2

[0040] A method for one-sided etching of a glass panel of the present invention comprises the following steps:

[0041] Step 1: Select a glass panel with a thickness of 0.5mm and wash it at 30°C for 5 minutes, then dry it naturally for later use;

[0042] Step 2: Cover the non-etching surface of the glass panel cleaned in step 1 with a layer of protective paper first, then cover the protective paper with a layer of film, the film completely covers the protective paper, and finally cover the back The board is adhered to the film with an acid-resistant tape;

[0043] Step 3: Lift the glass panel treated in step 2 with a rail for glass etching, hang it in the air, and then perform etching treatment on its etched surface;

[0044] Step 4: Carry out film removal treatment to the etched glass panel;

[0045] Step 5: Clean the glass panel after stripping.

[0046] Wherein, the cleaning solution in step 1 of the method for etching a single side of a glass panel of the present inven...

Embodiment 3

[0056] A method for one-sided etching of a glass panel of the present invention comprises the following steps:

[0057] Step 1: Select a glass panel with a thickness of 0.35mm, wash it at 25°C for 8 minutes, and dry it naturally for later use;

[0058] Step 2: Cover the non-etching surface of the glass panel cleaned in step 1 with a layer of protective paper first, then cover the protective paper with a layer of film, the film completely covers the protective paper, and finally cover the back The board is adhered to the film with an acid-resistant tape;

[0059] Step 3: Lift the glass panel treated in step 2 with a rail for glass etching, hang it in the air, and then perform etching treatment on its etched surface;

[0060] Step 4: Carry out film removal treatment to the etched glass panel;

[0061] Step 5: Clean the glass panel after stripping.

[0062] Wherein, the cleaning solution in step 1 of the method for etching a single side of a glass panel of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com