Pipeline heat transfer air cooler for powder

An air cooler and powder technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of large footprint, heavy equipment, complex structure, etc., and achieve low maintenance costs, The effect of small footprint and low flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

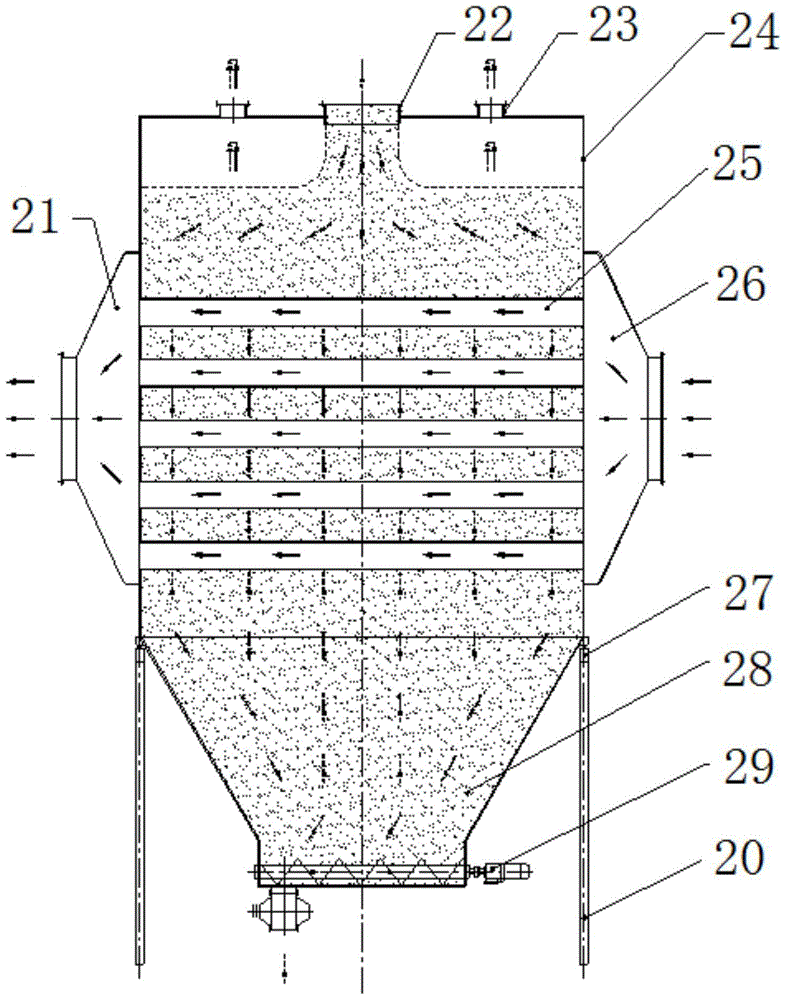

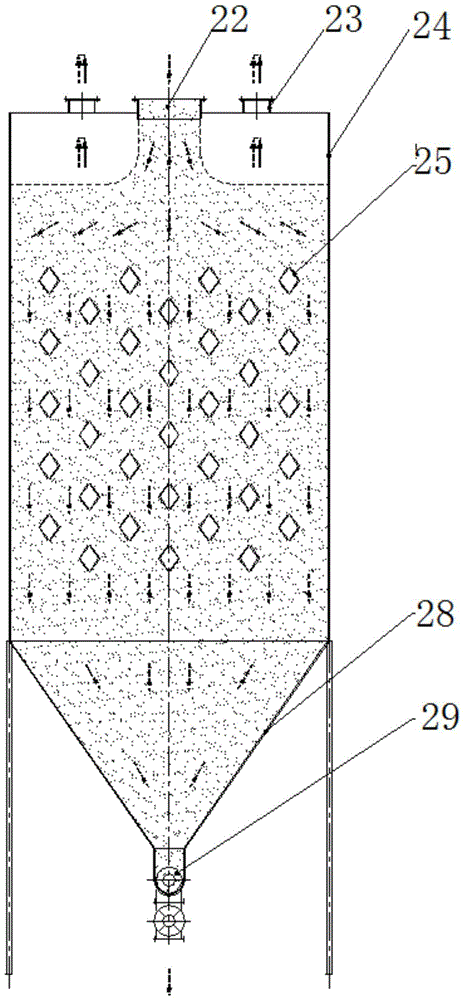

[0038] The pipe heat transfer air cooling zone for powder includes a box-shaped outer casing 24 , and a feeding port 22 is arranged on the top of the outer casing 24 for feeding high-temperature powdery materials into the outer casing 24 . A discharge port 28 is provided on the bottom of the outer shell 24 or on the side close to the bottom, for discharging the cooled powdery material. The discharge port 28 forms a cooling chamber together with the outer casing 24 . The bottom of the outer casing 4 is provided with a weighing sensor 27 for detecting the amount of powdery material stored inside the outer casing 24 . The discharge port 28 is provided with a powder conveying device 29 , and the powder conveying device 29 quantitatively sends the cooled powdery material away from the cooler according to the amount of the powdery material stored in the outer casing 24 . In this structure, the powdery material only runs downwards in the cooling chamber, not upwards.

[0039] The i...

Embodiment 2

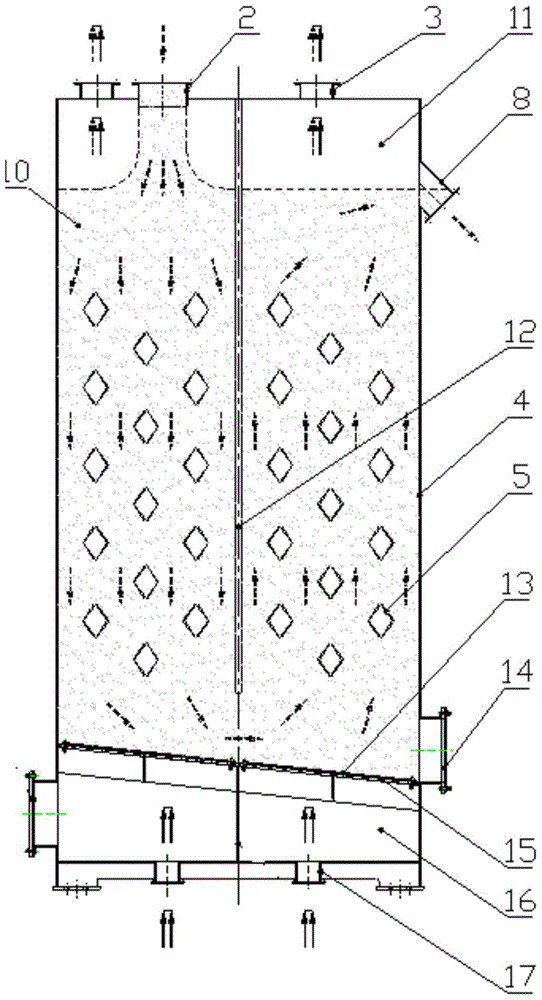

[0043] The air-cooling zone for powder with pipeline heat transfer includes a box-shaped outer casing 4 , and a feed inlet 2 is arranged on the top of the outer casing 4 for feeding high-temperature powdery materials into the outer casing 4 . The upper side of the outer shell 4 is provided with a discharge port 8 for discharging the cooled powdery material. The bottom area of the outer casing 4 is obliquely provided with an air-permeable layer 13, the air-permeable layer on the side of the feed port 2 is slightly higher than the air-permeable layer on the side of the discharge port 8, and the air-permeable layer 13 will cover the outer shell 4. It is divided into an upper cooling chamber and a lower plenum chamber 16 . The outer casing of the lower plenum chamber 16 is provided with an air inlet 17 for feeding air of a certain pressure, and the air of a certain pressure passes through the air-permeable layer 13 under the action of its own pressure, and in the air-permeable l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com