Insulating framework carrying stator winding and motor stator

A technology of insulating skeleton and stator winding, which is applied to the shape/style/structure of winding insulation, winding, electrical components, etc., which can solve the problems of easily scratched stator slot enameled wire and disordered wire arrangement, and reduce scratches on stator lead-out wires risk, neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

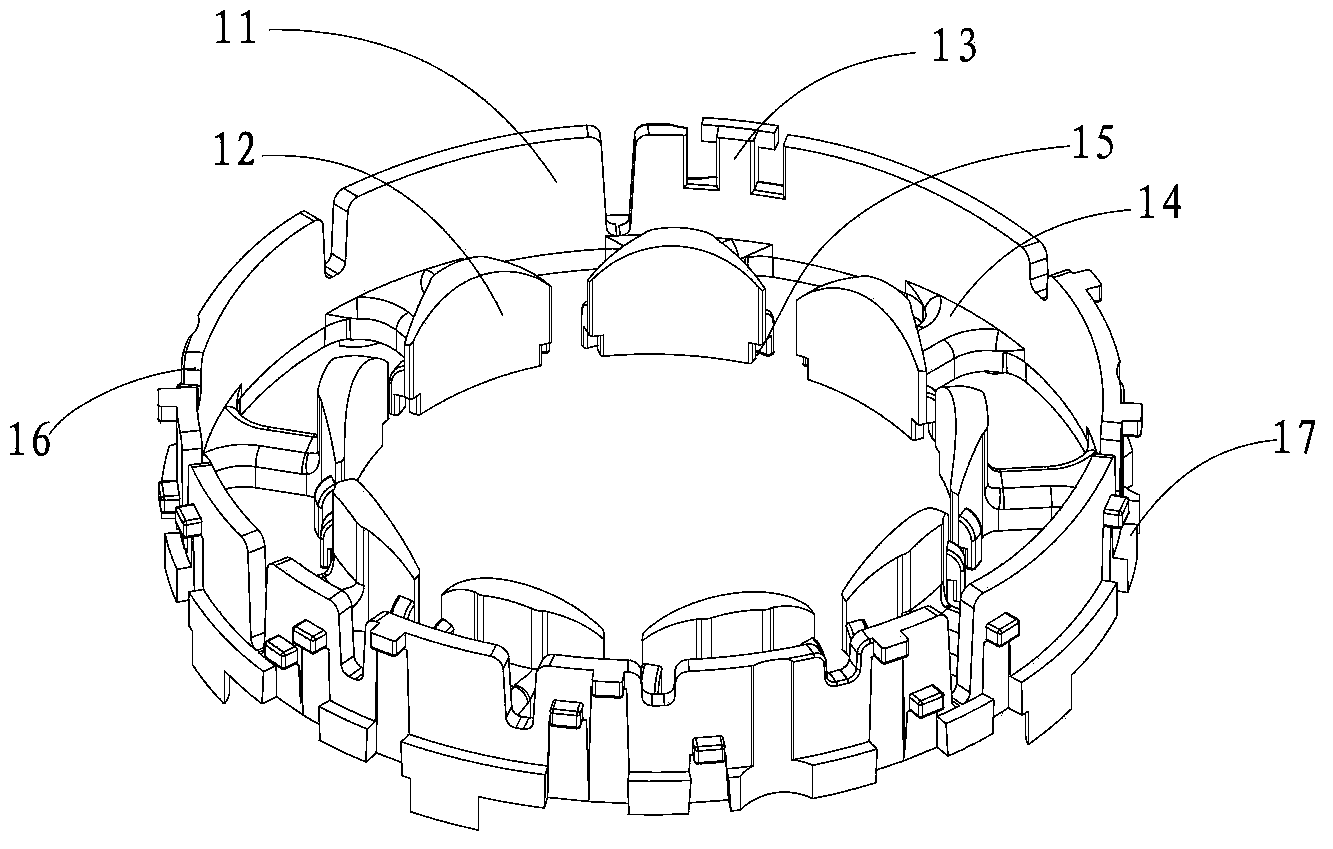

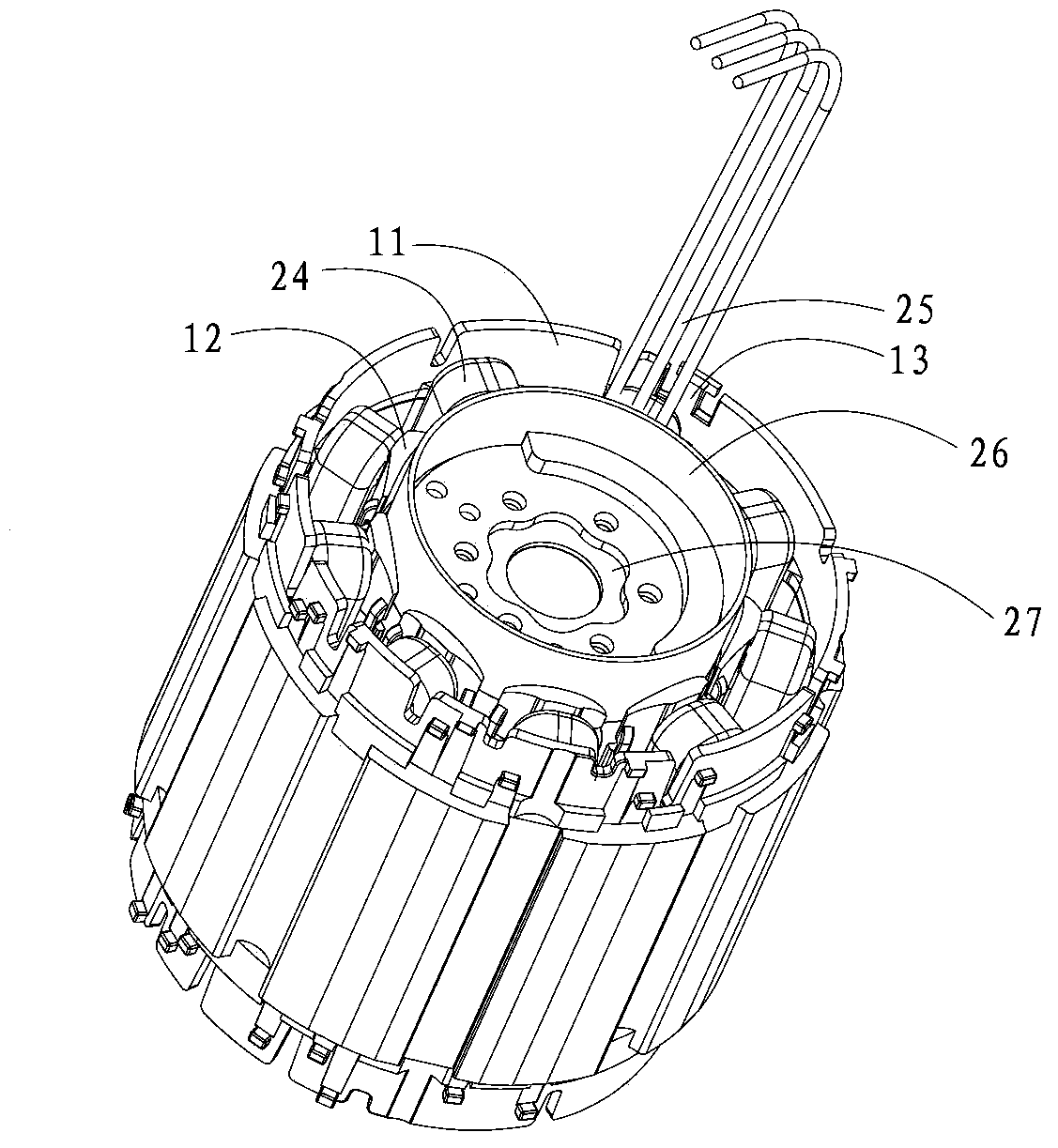

[0020] Such as figure 1 As shown, the insulating skeleton carrying the stator windings of the present invention includes an outer wall 11 and an inner wall surrounded in a ring shape, and a plurality of winding parts connected between the outer wall and the inner wall for winding the stator windings 14;

[0021] The inner wall is 2-4mm lower than the outer wall 11, and this height not only satisfies the higher slot fullness rate in the slot, but also makes the winding process of the motor stator more orderly;

[0022] Buckles 13 for fixing the lead-out wires of the stator winding are arranged on the edge of the outer wall 11 .

[0023] As a possible implementation, the buckle 13 is a "T"-shaped structure arranged on the outer wall, its transverse part is at the same height as the top edge of the outer wall, and the buckle and the outer wall a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com