High-temperature sensor for arrangement in a metal tube, especially inside the exhaust gas system of an internal combustion engine

A high-temperature sensor, metal tube technology, applied in the direction of temperature measurement in motors, diagnostic devices and instruments of exhaust gas treatment devices, etc., can solve problems such as rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

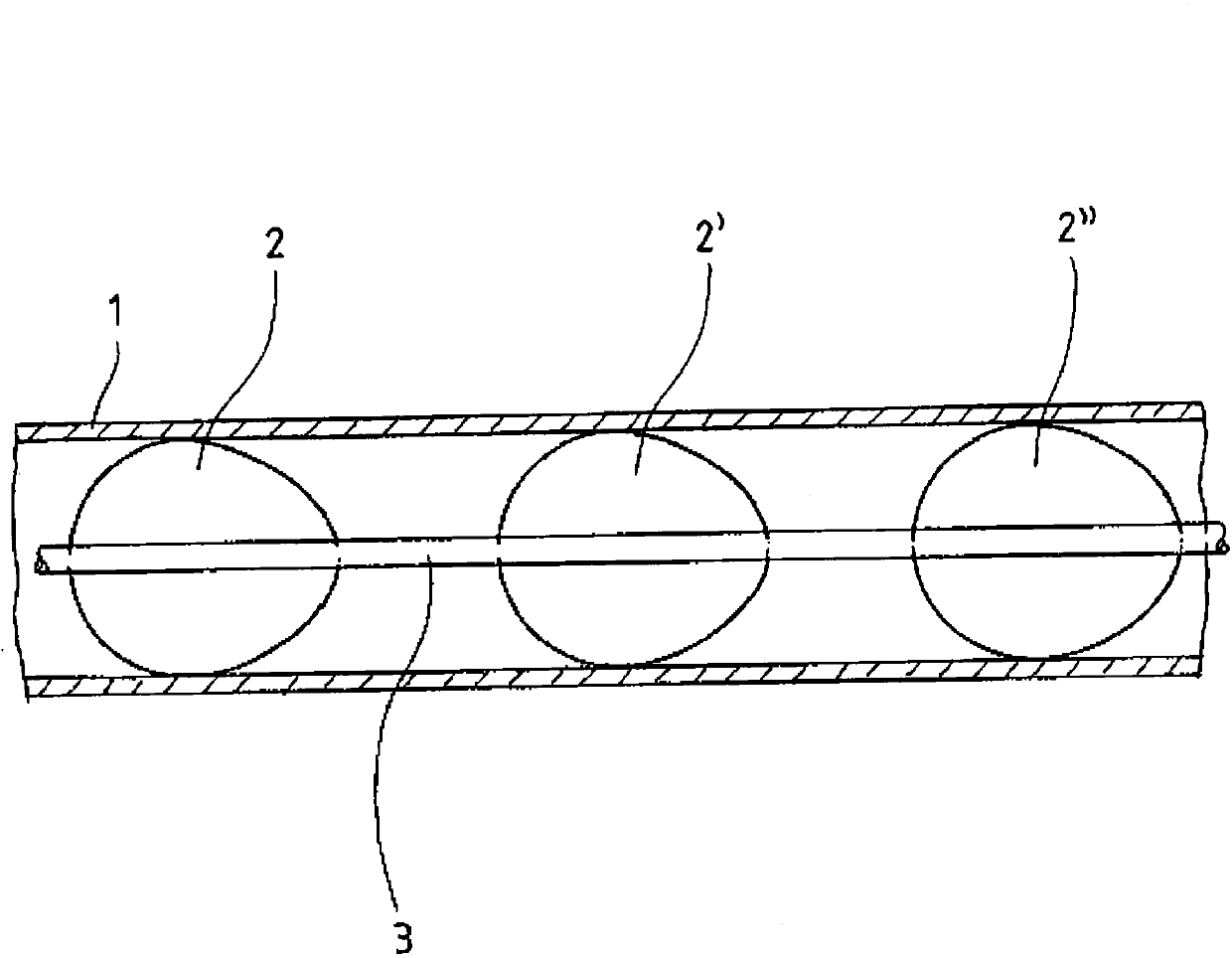

[0021] exist figure 1 shows a cross-sectional view of a metal tube 1 into which a spacer 2 , 2 ′, 2 ″ is penetrated in the manner of a string of pearls, connected to each other by a contact wire 3 .

[0022] Depending on the length of the contact wire, the number of spacers of such a contact arrangement can be arbitrary, however, always at least two spacers form the contact arrangement.

[0023] Contact wires are connected to sensors (eg high temperature sensors) not shown here, the measured values of which are supplied via the contact wires to electronics (not shown further), where the measured values are evaluated.

[0024] The metal pipe 1 can be led, for example, through associated bores into the exhaust system of the internal combustion engine, in order to detect corresponding exhaust gas values there by sensors located at the ends of the metal pipe.

[0025] The metal tube 1 is preferably made of chrome-nickel steel (eg Inconel 601), which is corrosion-resistant a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap