Slow start circuit of inverter welding machine with power correction circuit

A technology of slow start circuit and power correction, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of large volume and uneconomical, etc., and achieve the goals of reducing current impact, improving reliability, reducing power and volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

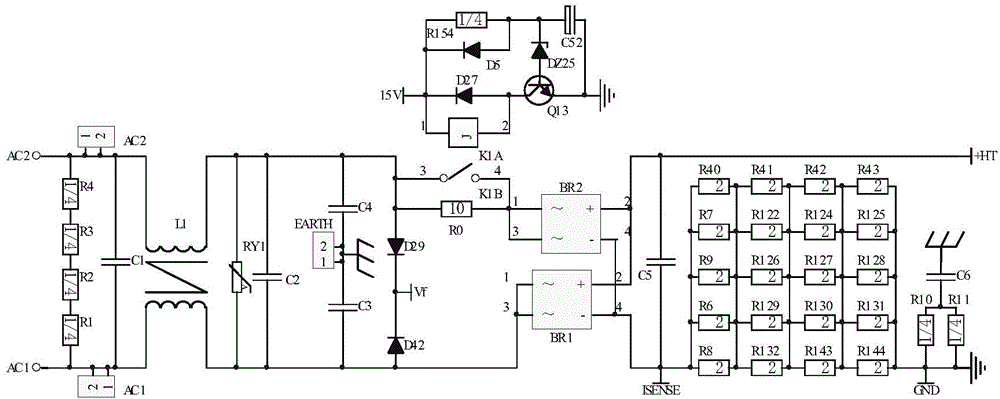

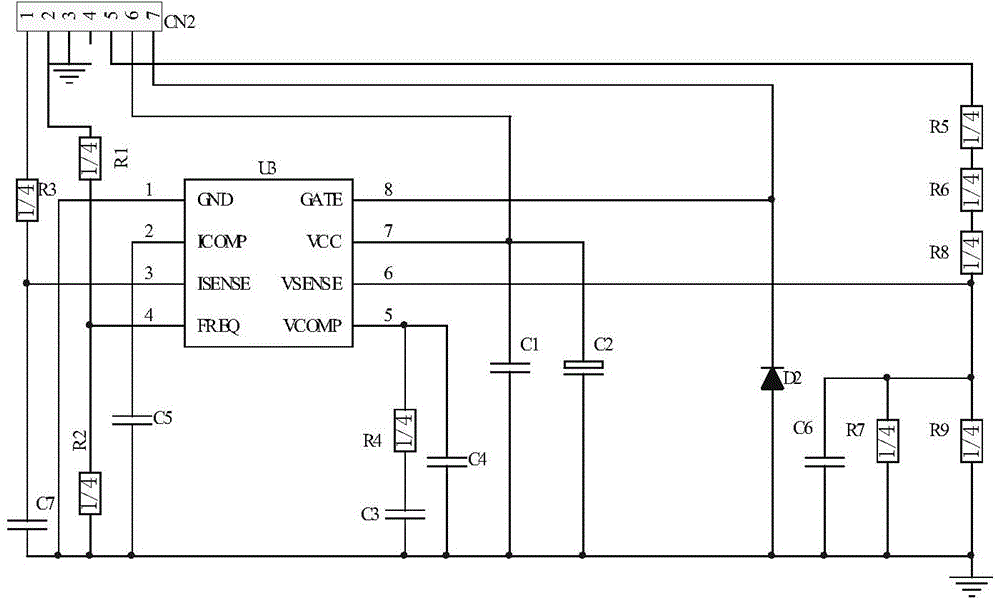

[0014] Such as figure 1 As shown, the start-up slow-start circuit mainly includes: slow-start resistor R0, relay K1, resistor R154, diodes D5, D27, voltage regulator tube DZ25, capacitor C52, and triode Q13. The starting resistor R0, bridge stack BR1 and BR2 provide DC power to the switching power supply after rectification. The switching power supply works and outputs a DC signal of 15V. 15V charges the capacitor C52 through the resistor R154. When the voltage reaches the regulator value of the voltage regulator DZ25 When the voltage regulator works, the triode Q13 is turned on, the coil K1A of the relay is energized, the contact K1B is closed, D27 is used to protect the relay when the welding is turned off, and D5 is used to discharge the capacitor C52 when the welding is turned off, so as to ensure the The slow start circuit is working normally. In this circuit, relay K1 is on image 3 The pull-in is done after the middle PWM output, and the charging time of the RC compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com