Heavy high-speed precise press body locking mechanism

A locking mechanism and press technology, applied in the field of presses, can solve the problems of complicated operation and poor safety, and achieve the effect of simple movement mode, simple structure and fast locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

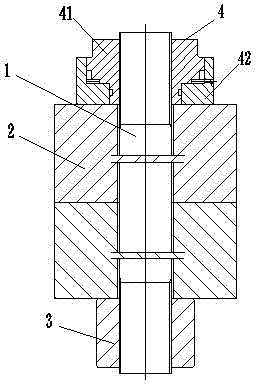

[0014] The present invention comprises a locking screw rod 1, and the locking screw rod 1 is vertically penetrated in each fuselage 2 to be tightened. 1 is provided with a locking device 4 on the top of the uppermost fuselage 2;

[0015] The structure of the locking device is: a piston 41 firmly connected with the locking screw 1, and a cylinder 42 connected with the uppermost body 2. The cylinder 42 is arranged on the outside of the piston 41 and forms a sealing fit.

[0016] A sealing ring is provided between the cylinder body 42 and the piston 41 .

[0017] The piston 41 and the locking screw 1 are connected by threads.

[0018] A guide ring guiding the locking screw 1 is provided between the locking screw 1 and the fuselage 2 .

[0019] The working process of the present invention is as follows: the present invention firstly puts the locking screw 1 on the fuselage 2, and sets the lock nut 3 at its lower end, and sets the locking device 3 at the upper end, wherein the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com