Combination tail lamp for automobile

A technology for automobiles, rear lights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated:

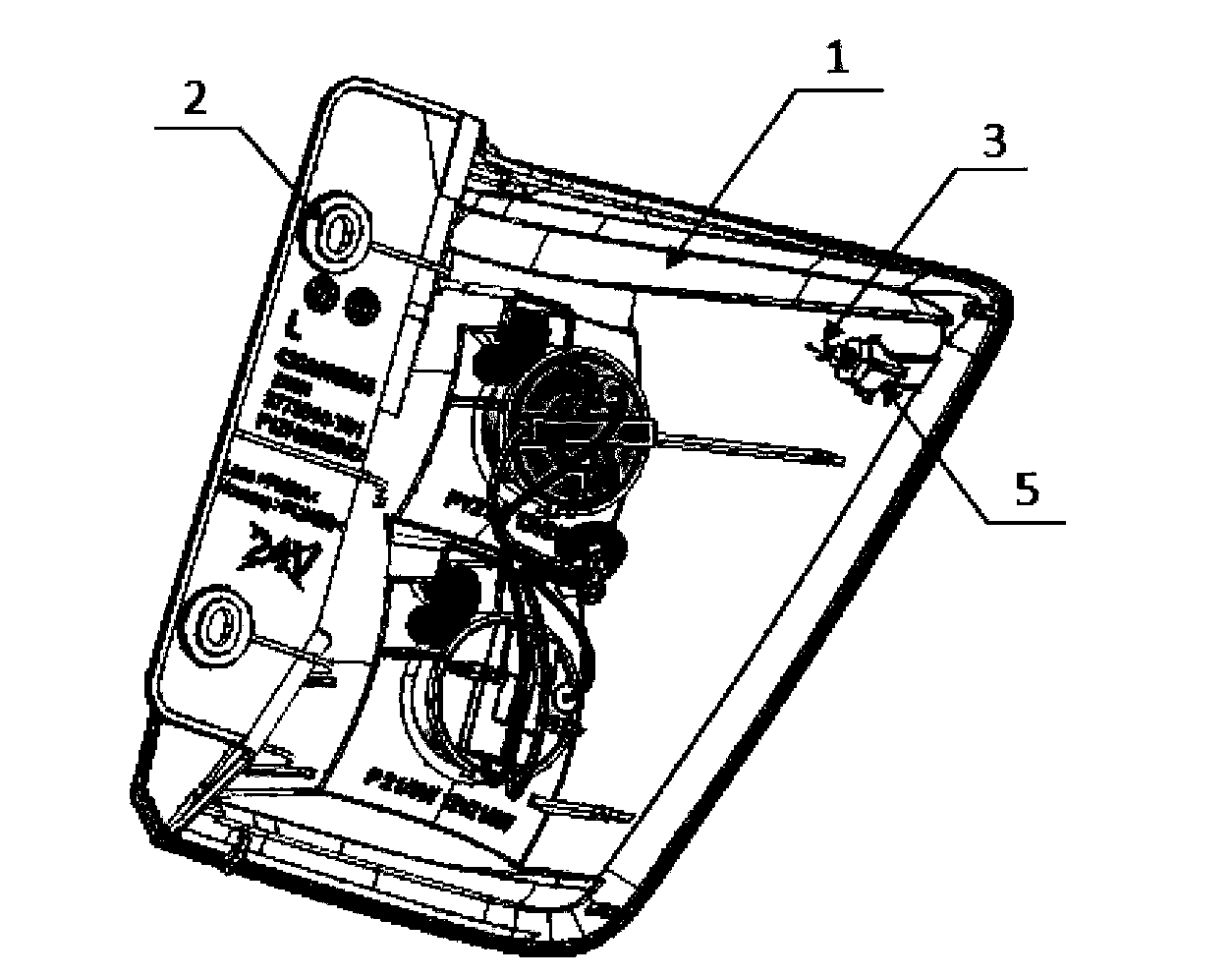

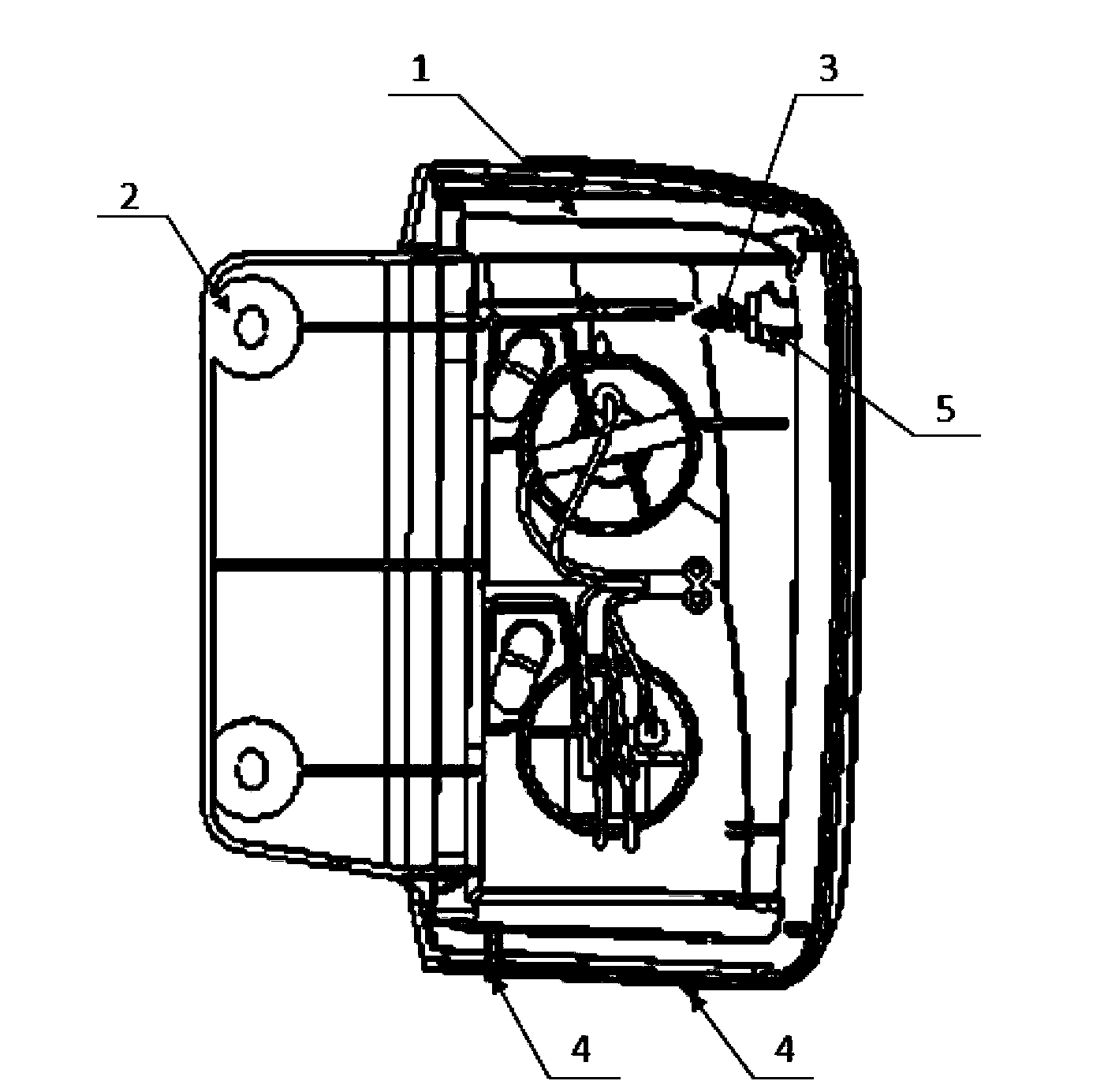

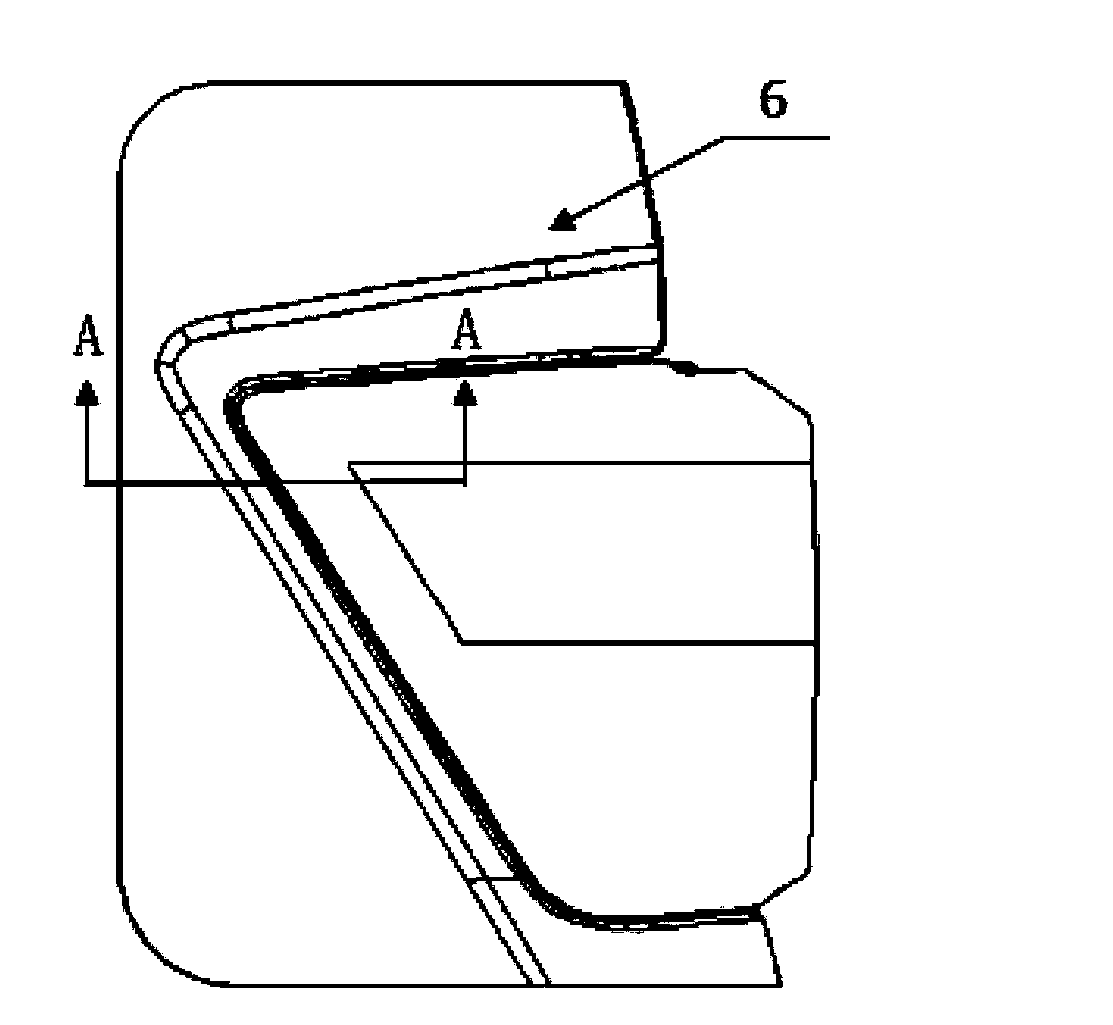

[0014] Such as figure 1 , figure 2 As shown, the automobile combined rear light includes a lamp housing 1, two mounting holes 2 are provided on the rear side of the lamp housing 1, and a cylindrical boss 5 is provided on the inner surface near the sharp corner of the lamp housing 1 side. The boss 5 is 10mm higher than the inner surface of the lamp housing 1, and a positioning pin 3 is arranged on the top of the boss. The positioning pin 3 is made of metal, and it is screwed on the top of the boss 5 by threads. , the axis of the mounting hole 2 is along the Y direction (that is, the vehicle length direction), the axis of the positioning pin 3 is parallel to the horizontal plane and perpendicular to the axis of the mounting hole 2, that is, the positioning pin is along the X direction (vehicle width direction), at the lower edge of the lamp housing 1 Two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com