Water transportation system for offshore lng storage tanks

A technology for water transportation and storage tanks, which is used in transportation and packaging, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc. It can solve the problems of stable storage system deformation, damage to transportation costs, etc. Risks, security, reduced barge transport and hoisting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

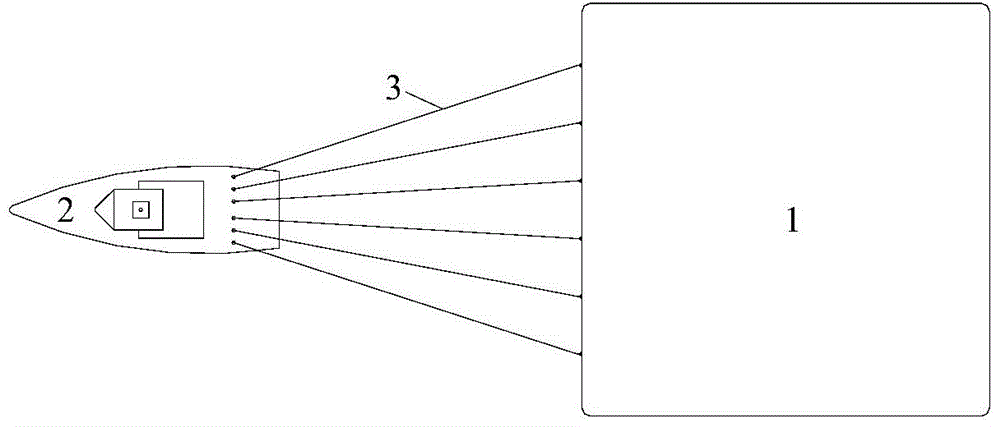

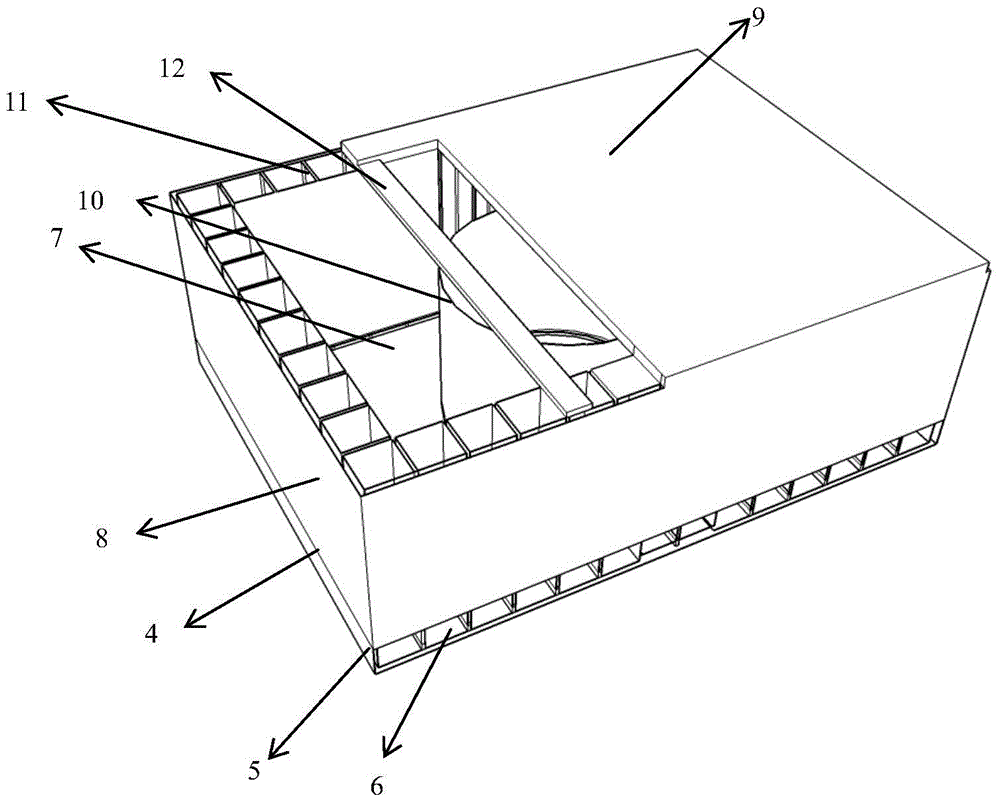

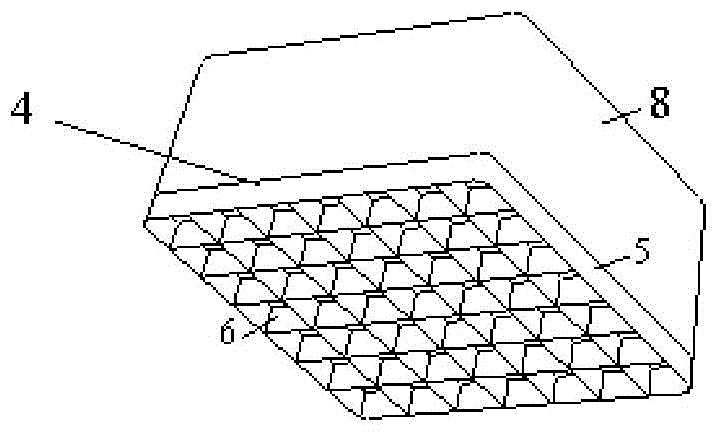

[0045] like figure 1 As shown, the water transportation system of the offshore LNG storage tank provided by the present invention includes an LNG storage module 1, a tugboat 2 and 6 steel cables 3; as Figure 2-Figure 4As shown, the LNG storage module 1 in the present invention includes a tank foundation and a caisson structure arranged on the tank foundation; the tank foundation is a cavity structure with an opening at one end surrounded by a roof 4 and a skirt 5, The top plate 4 is made of reinforced concrete, and the skirt plate 5 is made of steel plate. A plurality of evenly arranged open cabins 6 are arranged in the cavity structure, and a plurality of air valves (not shown in the figure) are arranged on the skirt plate 5, and the air valves communicate with the open cabins 6 so as to facilita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com