A sprocket accumulation type conveyor turning drive mechanism

A technology of accumulating and releasing conveyor and driving mechanism, applied in the direction of conveyor, transportation and packaging, can solve the problems of sprocket and trolley stuck, high manufacturing cost and high machining accuracy, and achieves the advantages of avoiding stuck, simple structure, Functionally Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

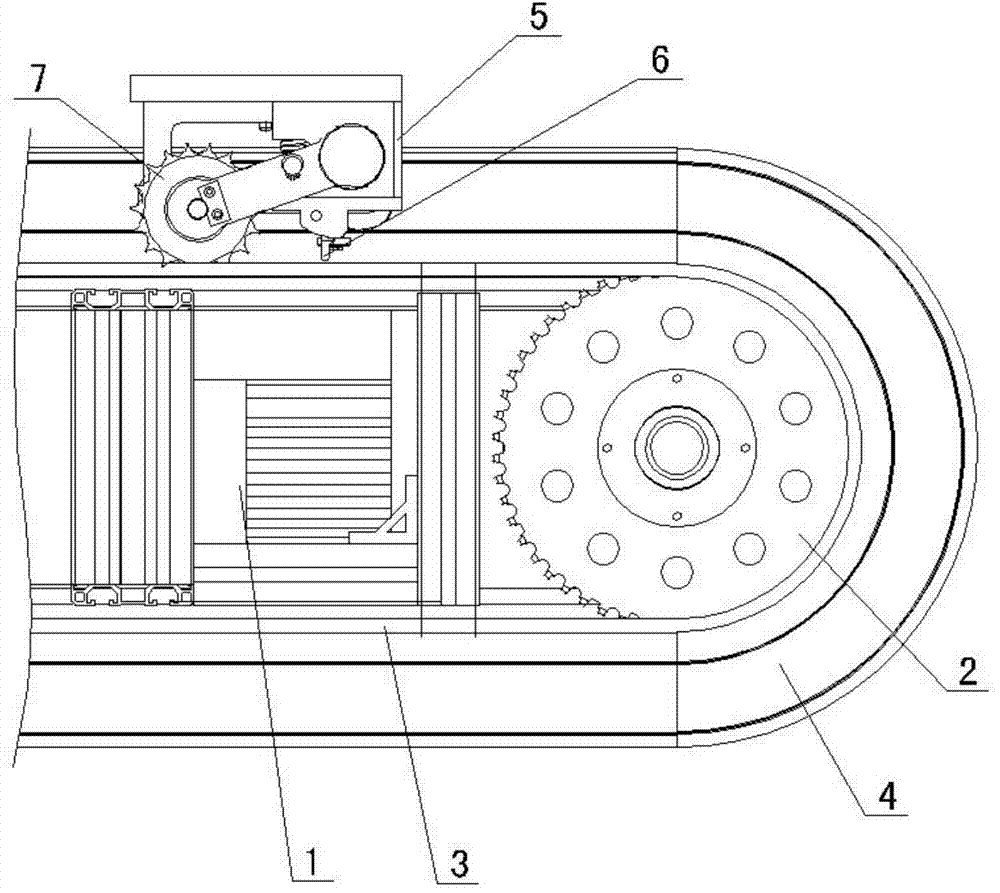

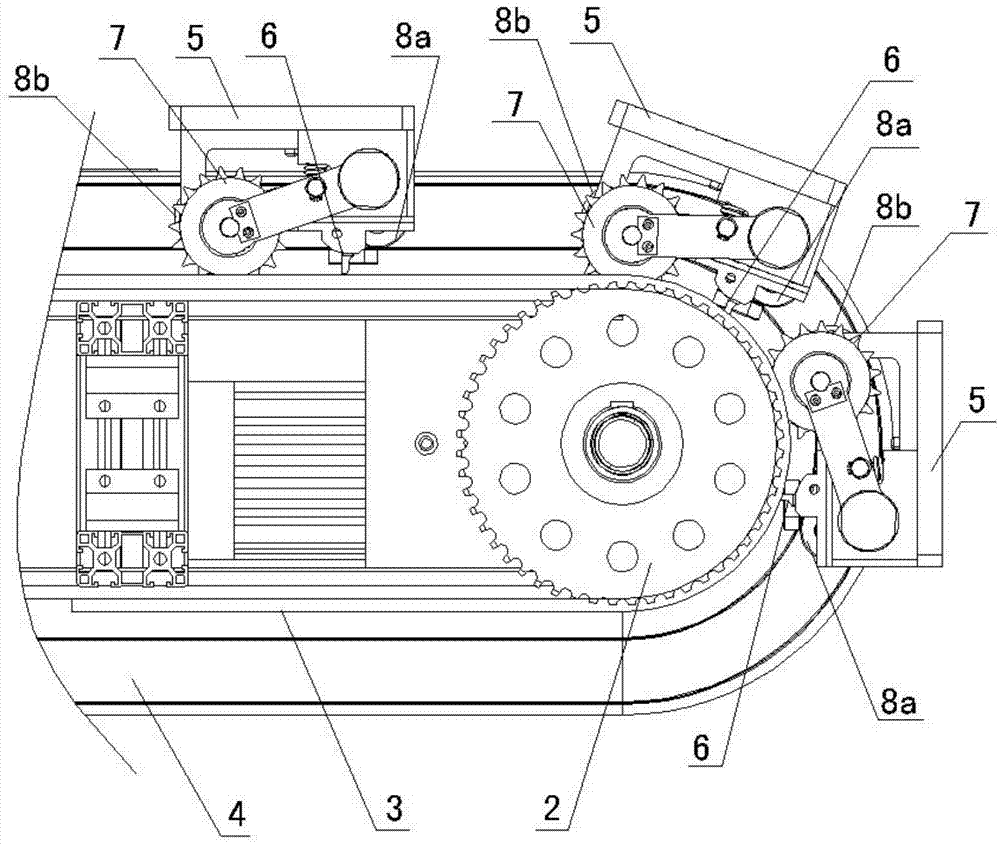

[0015] see figure 1 , figure 2 with image 3 , the structural form of the turning drive mechanism of the sprocket accumulation type conveyor in this embodiment is:

[0016] On the bed 4 with the circular track, a circular rotating chain 3 driven by the motor 1 and transmitted by the large sprocket 2 is set. The circular rotating chain 3 is a straight section at the position where it is out of engagement with the large sprocket 2. At the position engaged with the large sprocket 2, it is formed as an upside-down curve in the vertical plane.

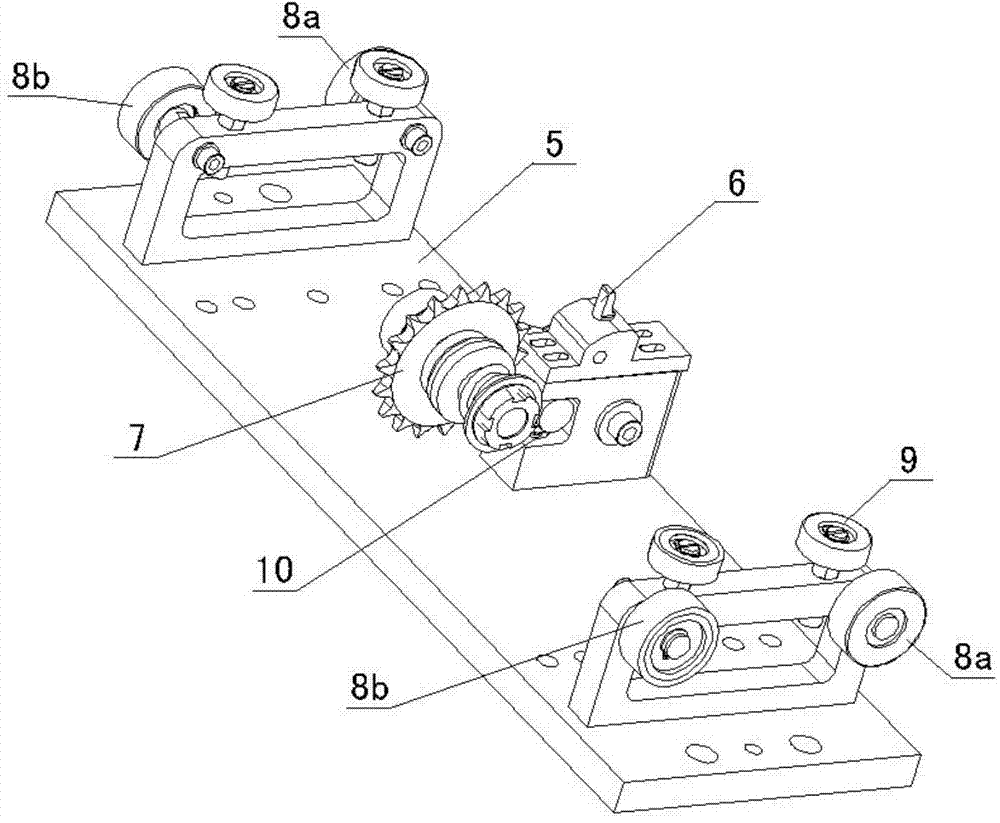

[0017] Such as figure 2 As shown, the structural form of the pallet trolley 5 is: the front wheels 8a and the rear wheels 8b support the trolley pallet 5, and the front wheels 8a and the rear wheels 8b run in the circulating track on the bed 4; at the bottom of the trolley pallet 5 A small sprocket 7 is set, and the small sprocket 7 is engaged with the circulating chain 3; at the bottom of the trolley pallet 5, a hanging tooth 6 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com