Isothiazole dye composition and method for applying isothiazole dye composition into short-process alkaline dyeing of polyester fabric

A technology of dye composition and polyester fiber, which is applied in the short-process alkaline dyeing of polyester fiber fabric, and the field of isothiazole dye composition, which can solve the problems of lack of bright colors and less color spectrum of dyes, and achieve excellent color fastness, Eliminate reduction cleaning, extend the effect of dye color spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the disperse dye composition specifically includes: mixing the above dye composition and a dispersing agent in a certain ratio, and micronizing by grinding to obtain the disperse dye composition.

[0067] Preferably, the mass of the diffusing agent is 0.8-5 times the mass of the dye composition.

[0068] Preferably, the diffusing agent is sodium methylene bismethyl naphthalene sulfonate, sodium methylene dinaphthalene sulfonate or a mixture of two, including diffusing agent NNO, dispersing agent MF, modified dispersion agent MF and dispersant CNF.

[0069] The preparation method of the disperse dye composition specifically includes: mixing the above dye composition and the dispersing agent according to the stated ratio, and micronizing by grinding to obtain the disperse dye composition.

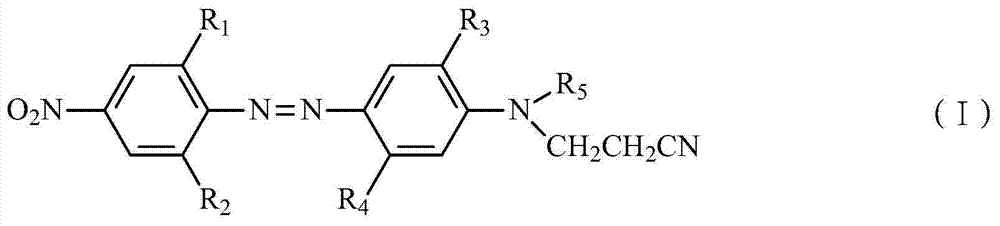

[0070] The present invention provides a method for carrying out short-process alkaline dyeing of polyester fiber fabrics based on the above-mentioned dispers...

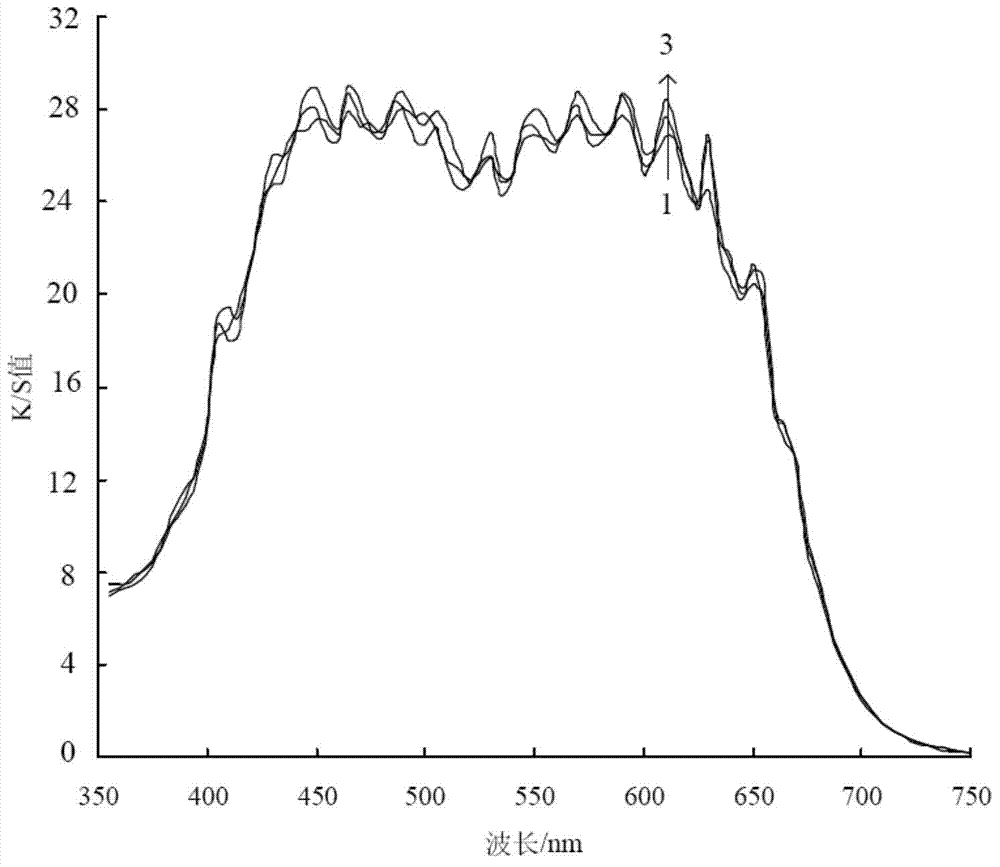

Embodiment 1

[0078] Mix 20 grams of dye (orange) with general formula (I-16) and 80 grams of dispersant MF with water, grind and disperse with a grinder until the particle size of the disperse dye is 1-3 μm, stop grinding, The orange dye powder was obtained by high temperature spray drying.

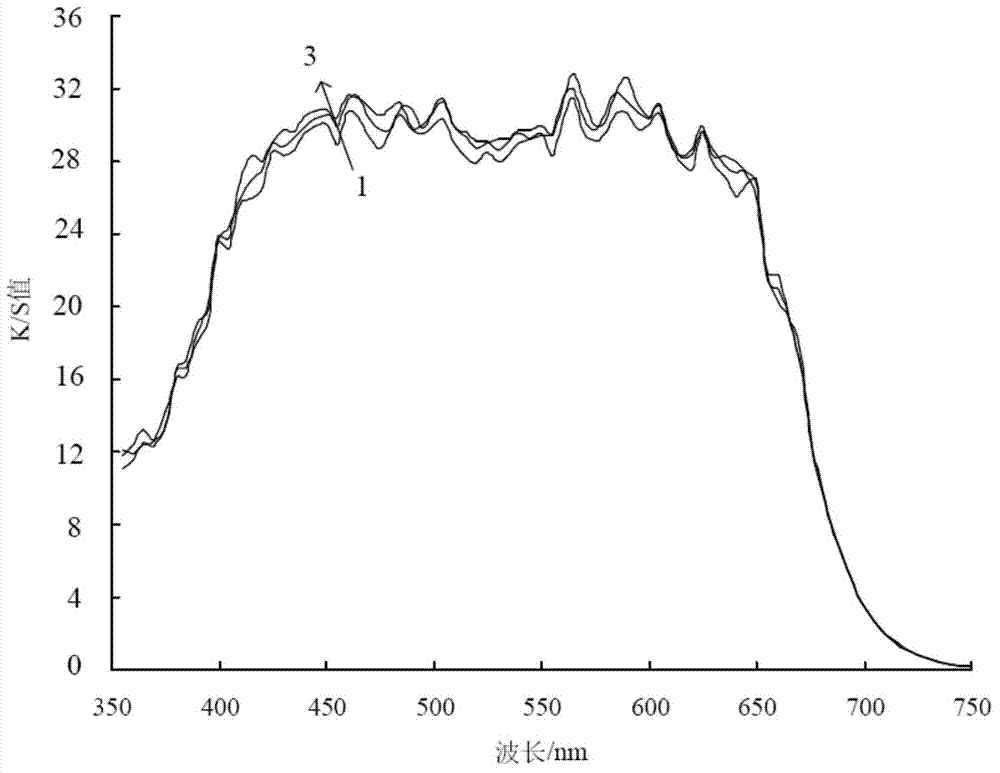

Embodiment 2

[0080] 5 grams of the dye (yellow) represented by the general formula (I-1), 35 grams of the dye (red) represented by the general formula (I-9) and 60 grams of dispersant MF are mixed with water and then mixed with a grinder Grinding and dispersing until the particle size of the disperse dye is 1-3 μm, stop grinding, and then spray-dry at high temperature to obtain orange dye powder (disperse dye composition).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com