Device capable of indicating packing compression status of valve stem

A technology of packing compaction and indicating valve, applied in valve device, valve details, engine components, etc., can solve problems such as affecting the use effect of packing, unable to accurately achieve the proper compacting state of packing, etc., to achieve convenient daily maintenance, simple structure, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

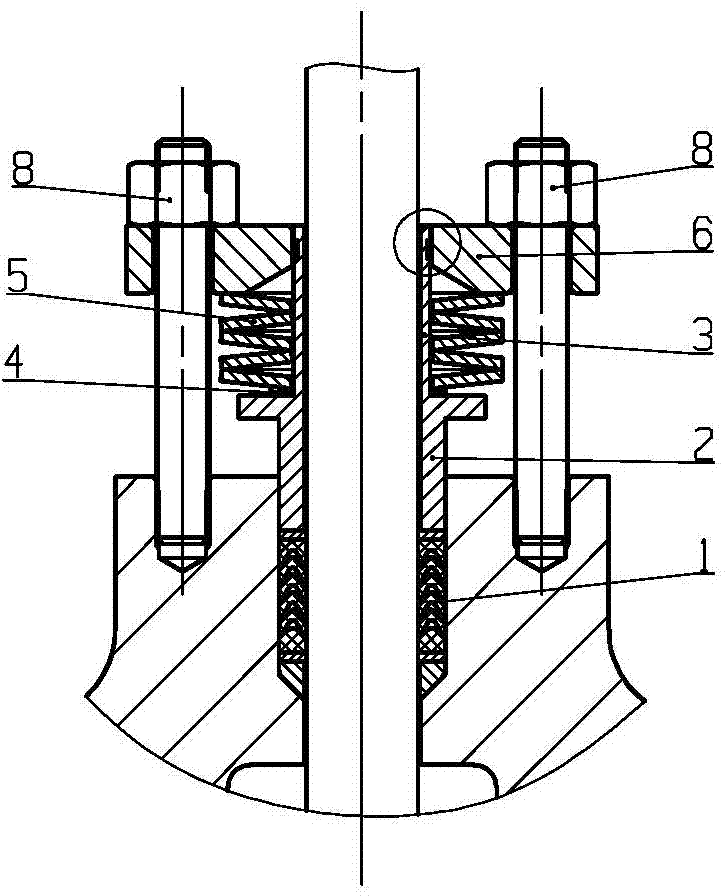

[0058] Example 1 as figure 1 , 2 As shown, the packing seal structure is compressed by the fastener 8 by pressing the packing gland 6 to compress the disc spring 5, the deformation force of the disc spring 5 acts on the packing cylinder 2, and compresses the packing 1, wherein the packing pressure The cylinder 2 and the guide cylinder 3 are fixedly connected.

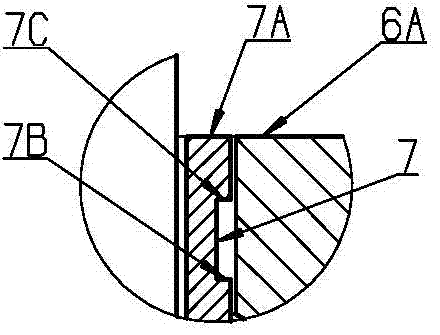

[0059] The specific implementation of the packing compaction state indicating structure of the packing sealing structure is as follows: an annular groove 7 is formed on the guide cylinder 3 by machining, and eye-catching pigments are filled in the annular groove 7 . The lower end surface of the annular groove 7 is the maximum compression scale indication surface 7B, the upper end surface of the annular groove is the minimum compression scale indication surface 7C, the upper end surface of the guide cylinder 3 is the zero scale indication surface 7A, and the upper surface of the packing gland 6 is It is pointer 6A. Befo...

Embodiment 2

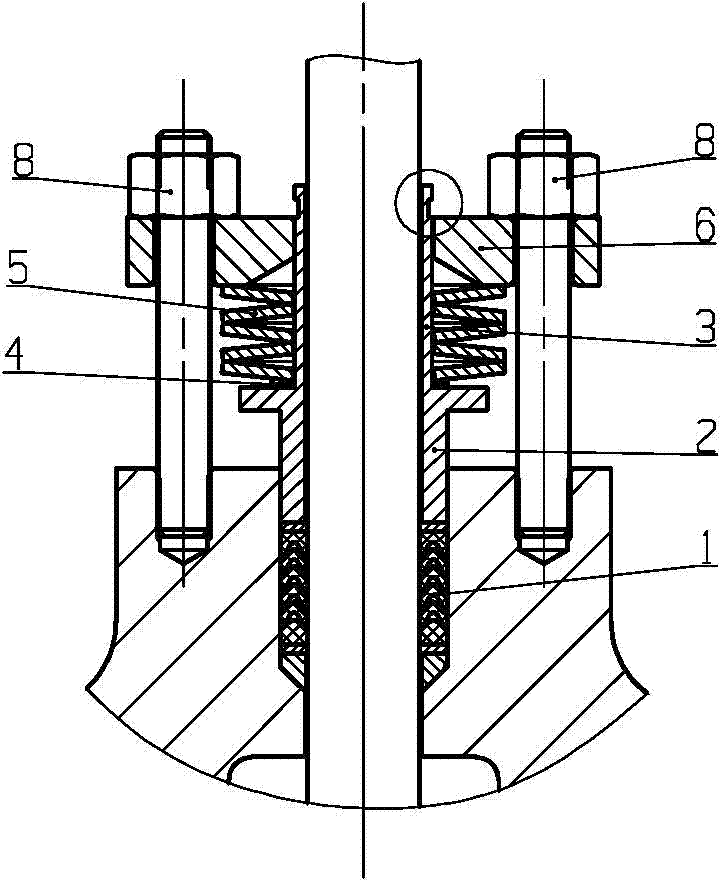

[0063] Such as Figure 6 , 7 As shown, the packing sealing structure adopts a small disc spring 5, which is installed on the fastener 8, and the disc spring 5 is directly compressed by the fastener 8, and the resultant force of deformation of several groups of disc springs 5 acts on the packing gland 6 , and compress the packing 1 through the packing cylinder 2.

[0064] The specific implementation of the packing compaction state indicating structure of the packing sealing structure is as follows: each set of pressing devices composed of fasteners 8 and disc springs 5 is provided with the same compacting state indicating structure. An annular groove 7 is formed on the guide cylinder 3 by machining, and eye-catching paint is filled in the annular groove 7 . The upper end surface of the annular groove 7 is the maximum compression scale indication surface 7B, the lower end surface of the annular groove is the minimum compression scale indication surface 7C, the lower end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com