Water rocket automatic filling system

An automatic filling and water rocket technology, which is applied in the direction of rocket launchers, offensive equipment, weapon types, etc., can solve the problems of time-consuming, laborious, and difficult manual filling methods, and achieve the effect of light structure and avoiding backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In conjunction with the accompanying drawings, the present invention will be described in further detail.

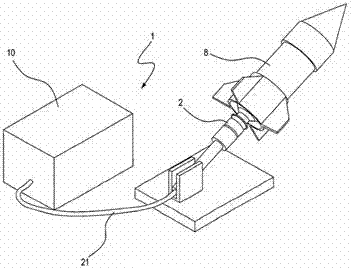

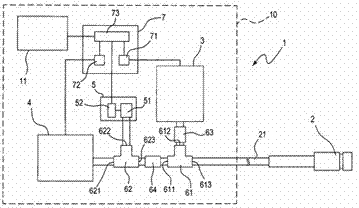

[0015] The water rocket automatic filling system of the present invention is characterized in that: the automatic filling system 1 of the water rocket 8 includes a filling joint 2, a water adding device 3, a pressure source 4, a pressure sensing device 5, a three-way pipe 61, a three-way pipe two 62, One-way valve 63, one-way valve two 64 and control circuit 7; except for the filling joint 2, the other parts are arranged inside a box body 10, and the filling joint 2 extends to the water rocket through the hose 21 Launcher. The three-way pipe 61 has a first nozzle 611 , a second nozzle 612 and a third nozzle 613 , and the water adding device 3 is connected to the second nozzle 612 . The three-way pipe two 62 has a first nozzle two 621, a second nozzle two 622 and a third nozzle two 623, the pressure source 4 is connected to the first nozzle two 621, and the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com