Bracket vehicle with multi-attitude adjusting function

A support vehicle, multi-stance technology, applied in the directions of weapon accessories, ammunition, offensive equipment, etc., can solve the problems of single function and low degree of integration, and achieve the effect of convenient maintenance, reducing the number of accessories, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

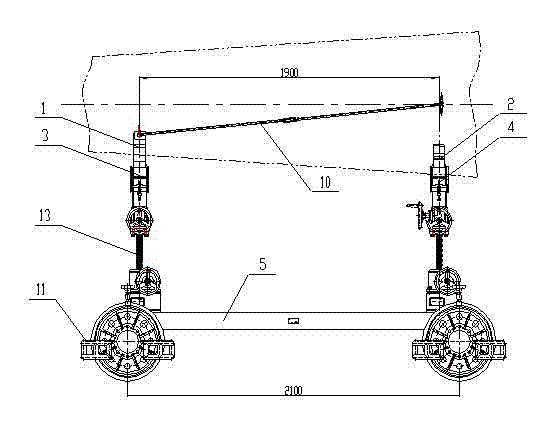

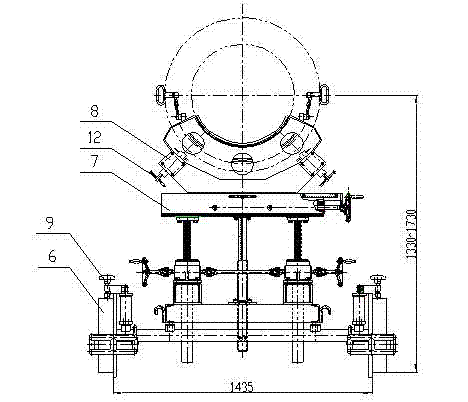

[0013] A multi-posture adjustment bracket vehicle, comprising: a front bracket 1, a rear bracket 2, a front bracket 3, a rear bracket 4, a vehicle frame 5, a wheel set 6, a beam seat 7, a roller set 8, and a brake device 9 , Pull rod group 10, protective frame 11, stop clamp 12 and screw jack 13.

[0014] The wheel set 6 is fixed on the vehicle frame 5 by U-shaped bolts, and screw jacks 13 are installed at the four corners on the vehicle frame 5, and the left and right two screw jacks 13 are connected together by couplings, and the top of each screw jack 13 Fastened with the beam seat 7 by bolts, the front bracket 3 and the rear bracket 4 are respectively placed on the beam seat 7 and can move forward and backward on the beam seat 7; A roller group 8 and two stop clamps 12, a roller group 8 is respectively installed on both sides of the front bracket 3 and a rear bracket 4 inside, and a roller group 8 is respectively installed on both sides of the front bracket 3 and on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com