Non-destructive testing device and method for reinforced concrete bridge steel bar corrosion

A reinforced concrete, non-destructive testing technology, applied in the direction of material magnetic variables, etc., can solve the problems of invisible, thick bridges, difficult steel bars, etc., and achieve the effects of strong coverage, comprehensive assurance, high detection accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

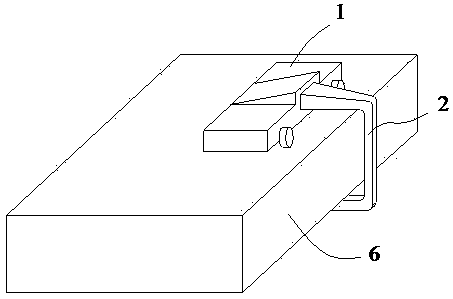

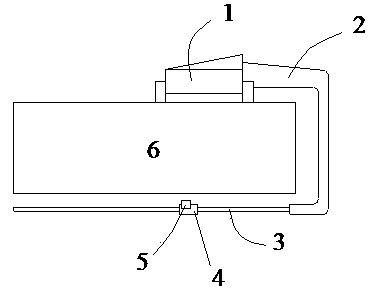

[0017] A non-destructive detection device for steel bar corrosion of reinforced concrete bridges, the non-destructive detection device is composed of a transmission trolley 1, a connecting bracket 2, a guide rod 3, a transmission device 4 and a detection device 5; the transmission trolley 1 is placed on the upper end surface of the bridge, and the transmission The trolley 1 can move back and forth on the bridge in one direction; one end of the connecting bracket 2 is connected to the transmission trolley 1, and the other end of the connecting bracket 2 is connected to the guide rod 3. The guide rod 3 is located under the bridge, and the axial direction of the guide rod 3 is parallel to the lower end surface of the bridge. And the axial direction of the guide rod 3 is perpendicular to the moving direction of the transmission trolley 1; the transmission device 4 is arranged on the guide rod 3, the detection equipment 5 is connected with the transmission device 4, and under the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com