A high-power triple frequency ultraviolet solid-state laser integrated device

A technology of solid-state lasers and integrated devices, used in lasers, laser components, phonon exciters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the invention will be described in detail below in conjunction with the accompanying drawings.

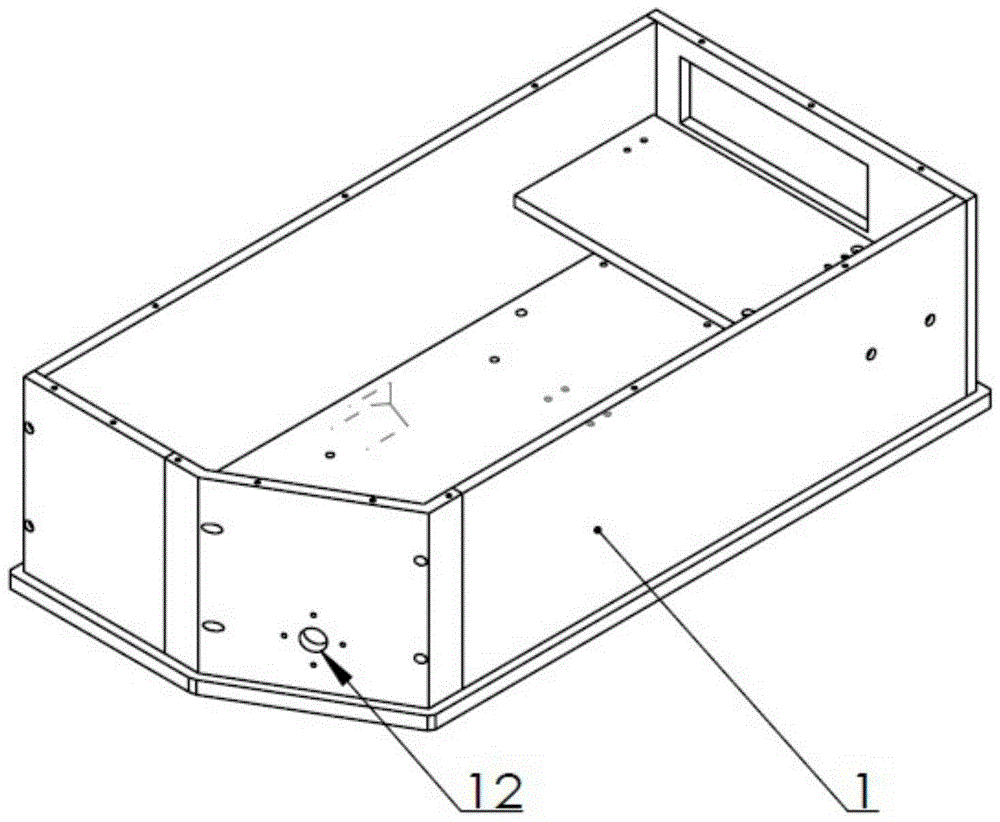

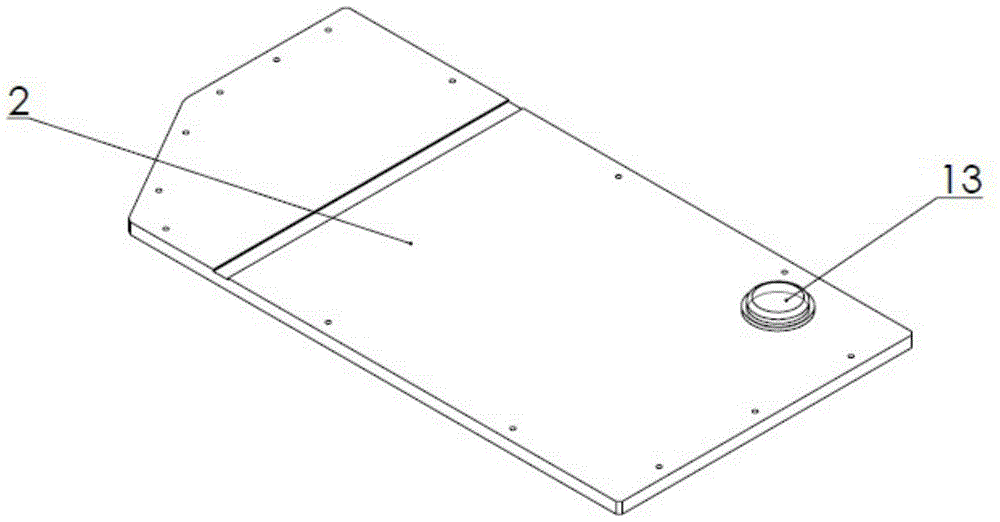

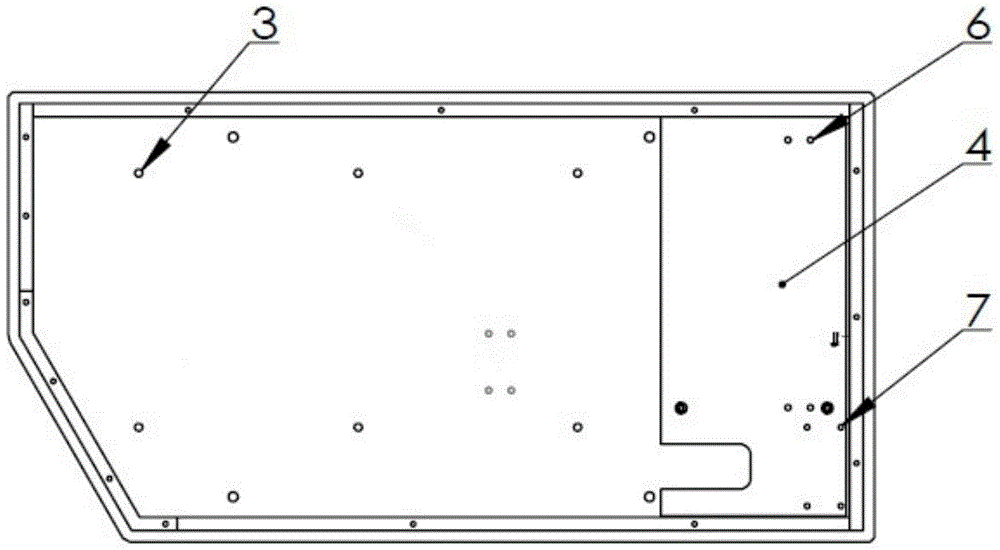

[0015] Such as Figure 1-5 As shown, a high-power triple frequency ultraviolet solid-state laser integrated device, the device includes a box 1 and a box cover 2; specifically, the box 1 includes a frequency doubling device installation hole 3, separate Q-switching controller and temperature Separation plate for furnace control controller 4, installation hole for temperature control furnace 5, installation hole for Q-switching controller 6, installation hole for outlet water separator 7, installation hole for water inlet separator 8, installation hole for pump module electrode 9 , Partition plate support rod a10, partition plate support rod b11, light outlet 12; the box cover 2 is provided with a Q-switching controller vent 13; the bottom of the box body 1 is equipped with a frequency multiplication device installation hole 3, temperature control furnace Moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com