Filling connector, container, filling method and filling nozzle

A technology for connectors and containers, applied in container filling methods, equipment loaded into pressure vessels, lifting valves, etc., to achieve a high degree of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

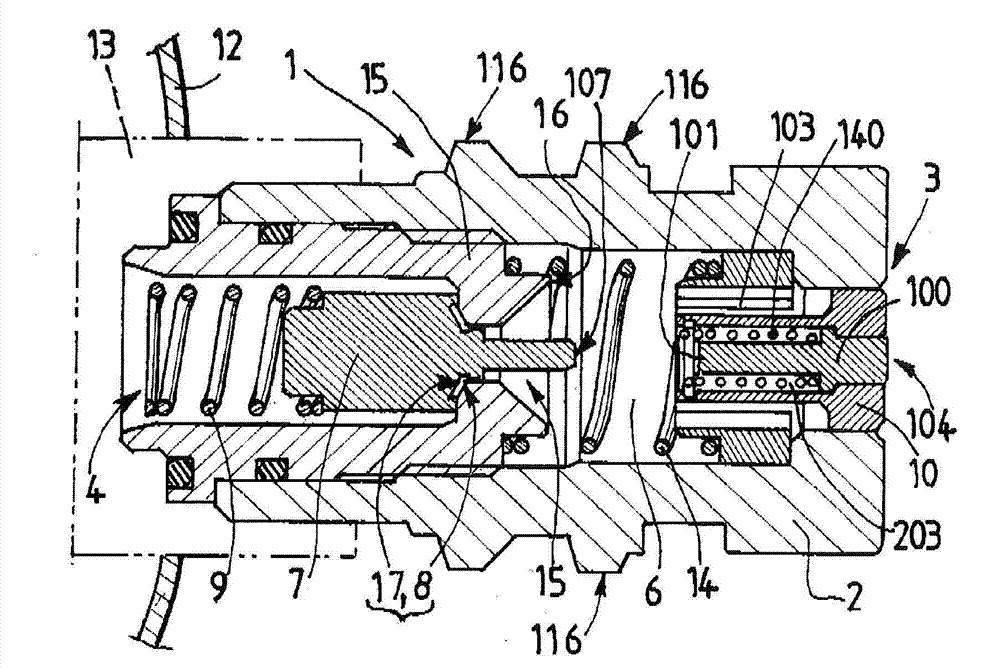

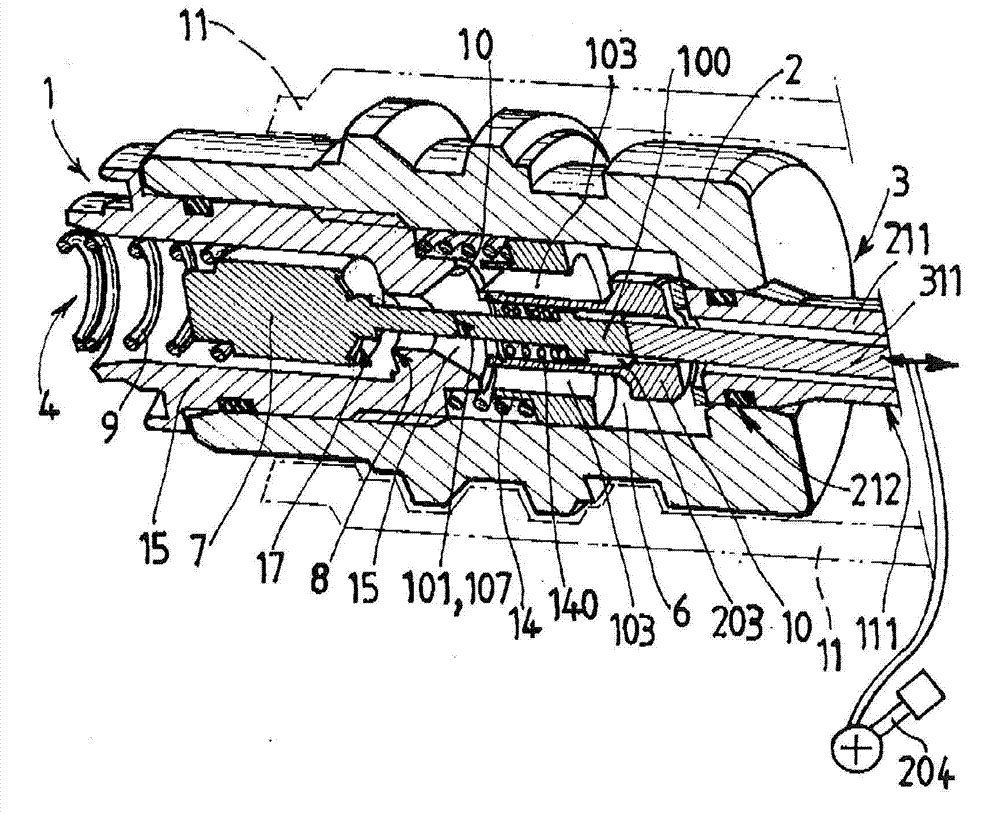

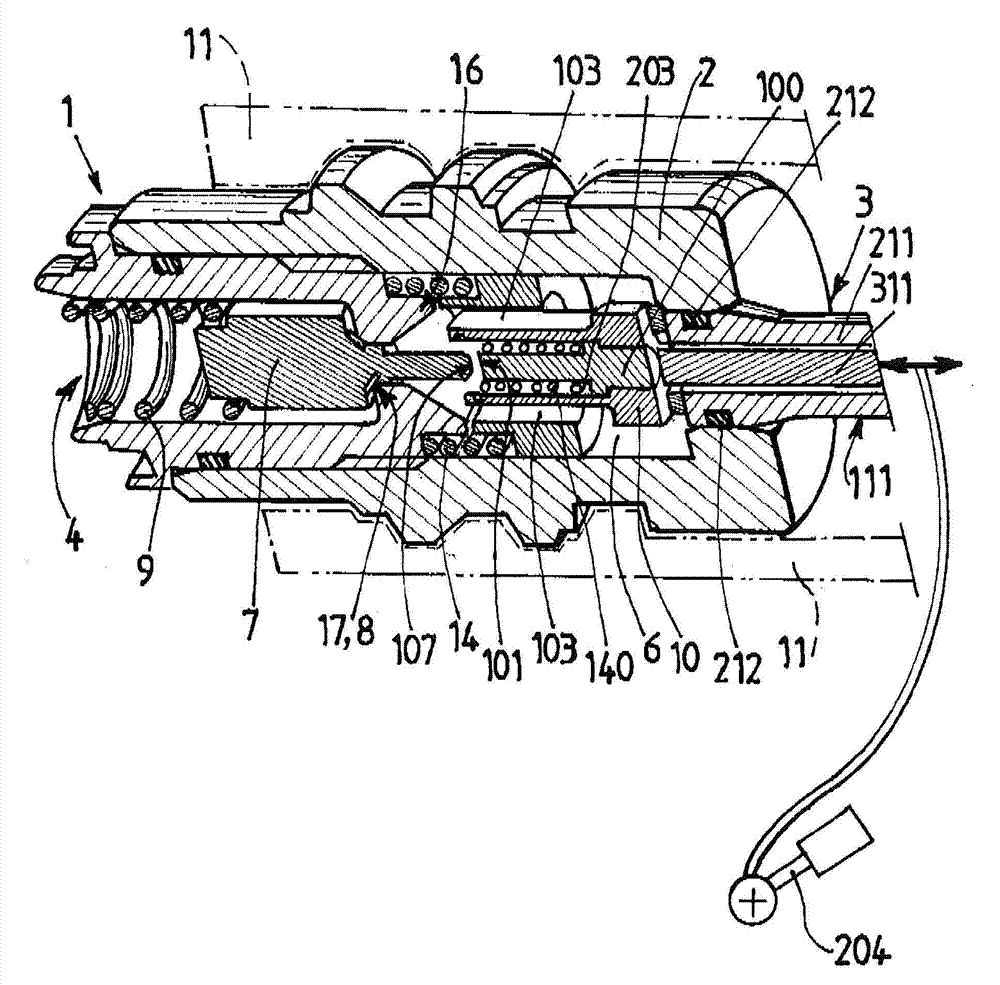

[0107] see figure 1 , the stuffing connector 1 comprises a body 2 which is, for example, substantially cylindrical. The body 2 delimits an internal filling circuit 6 between an upstream end 3 for connection to a filling socket and a downstream end 4 for connection to a container of pressurized gas (via, for example, the interior of a tap. circuit).

[0108] exist figure 1 In the example of , the downstream end of the portion of the connector 1 is fixed to the faucet 13 , for example by screwing. The tap 13 (shown in dashed lines) is secured to the orifice of a container of pressurized fluid, such as a bottle 12 .

[0109] The upstream end 3 of the circuit 6 (and of the connector 1 ) can be closed again selectively by a dust valve element 10 , 100 movable in the body 2 of the connector.

[0110] The anti-dust valve element 10, 100 is selectively movable (preferably translated) in the body 2 between an upstream position in which the upstream end 3 of the circuit 6 is closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com