V-type device lifting mechanism in capsule production system

A lifting mechanism and a technology for preparing capsules, which are used in capsule delivery, drug delivery, pharmaceutical formulations, etc., can solve the problems of reduced production efficiency, difficult synchronous driving, production waste, etc. Capsule efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

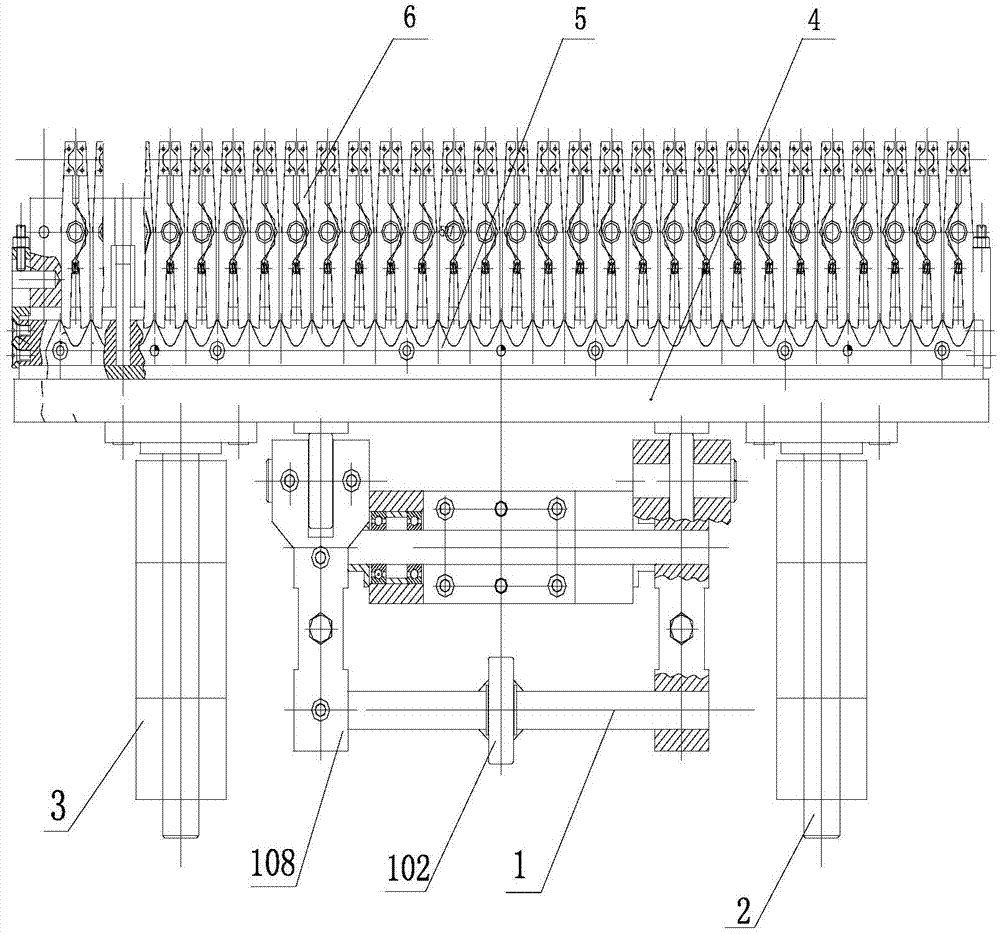

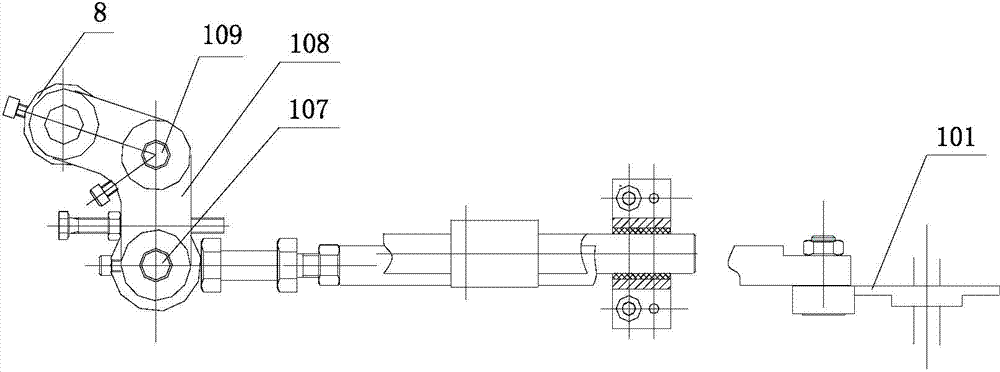

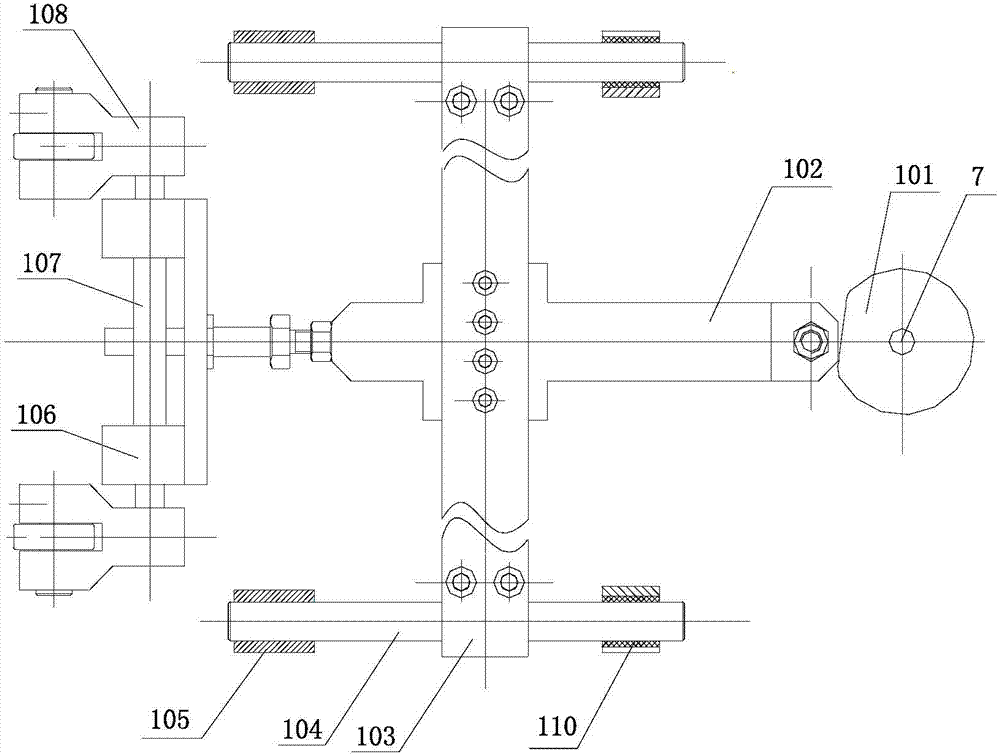

[0019] Example: such as figure 1 As shown, the V-shaped device lifting mechanism of the present invention is connected to the automatic machine of the capsule production system, including a drive spindle 7 connected to the automatic machine, a clamp transmission mechanism 1, a V-shaped device seat 4, and a plurality of V-shaped devices 5 And a plurality of clamps 6, the plurality of V-shaped devices 5 are an integrated structure arranged side by side, and clamps 6 are respectively arranged on it, and the integrated V-shaped device 5 is fixed on the V-shaped device seat 4, and the V-shaped device 5 is fixed on the V-shaped device seat 4. The device base 4 is connected with a guide column 2, and the guide column 2 is connected to the automatic machine frame through a linear bearing 3. One end of the clamp transmission mechanism 1 is connected to the driving spindle 7, and the other end is a working end, which is connected with the V-shaped device base 4. Contact each other to pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com