Control device of fuel injection device

A technology of a fuel injection device and a control device, which is applied in the directions of fuel injection device, fuel injection control, valve device, etc., can solve problems such as flow difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

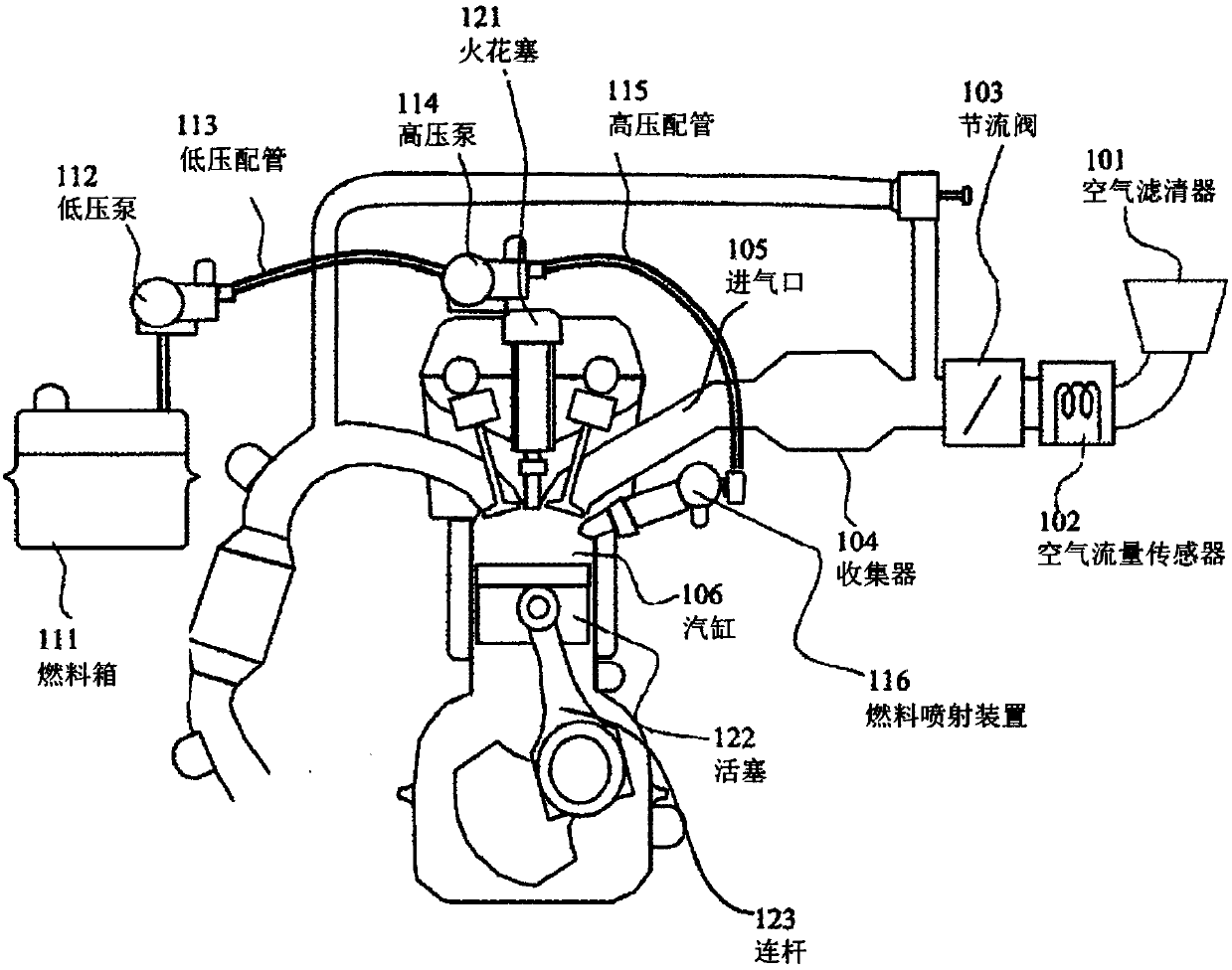

[0029] figure 1 An internal combustion engine equipped with a fuel injection device controlled by a control device according to the invention is shown. In the internal combustion engine, air and fuel are sucked into the cylinder 106, and these mixed gases are ignited by the spark plug 121 to explode, and the piston 122 reciprocates due to the energy of the explosion. This reciprocating motion is converted into rotational motion of the crankshaft by a link mechanism including the link 123 and the like, and becomes a driving force for moving the vehicle.

[0030] The air is filtered by the air filter 101 , the flow rate is adjusted by the throttle valve 103 , and flows into the cylinder 106 through the collector 104 and the intake port 105 . An air flow sensor 102 is provided between the air cleaner 101 and the throttle valve 103, and measures the amount of air taken in by the internal combustion engine. On the other hand, the fuel in the fuel tank 111 is sent to the low-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com