Anti-leakage sealing method of double-stage material push centrifugal machine

A centrifuge and dynamic sealing technology, applied in centrifuges, engine seals, centrifuges with rotating drums, etc., can solve the problems of increasing the residual moisture content of solids, and achieve the effect of improving the effect of solid-liquid separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

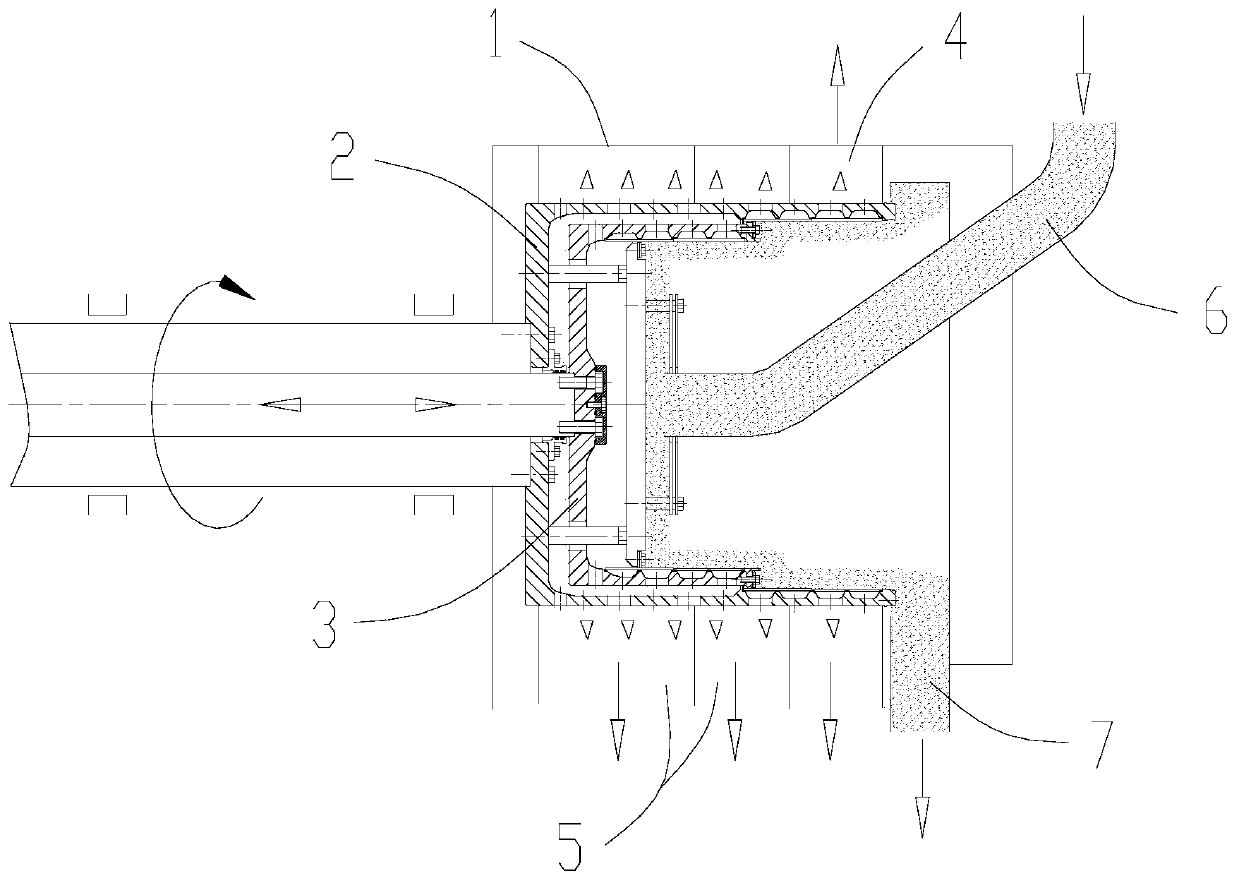

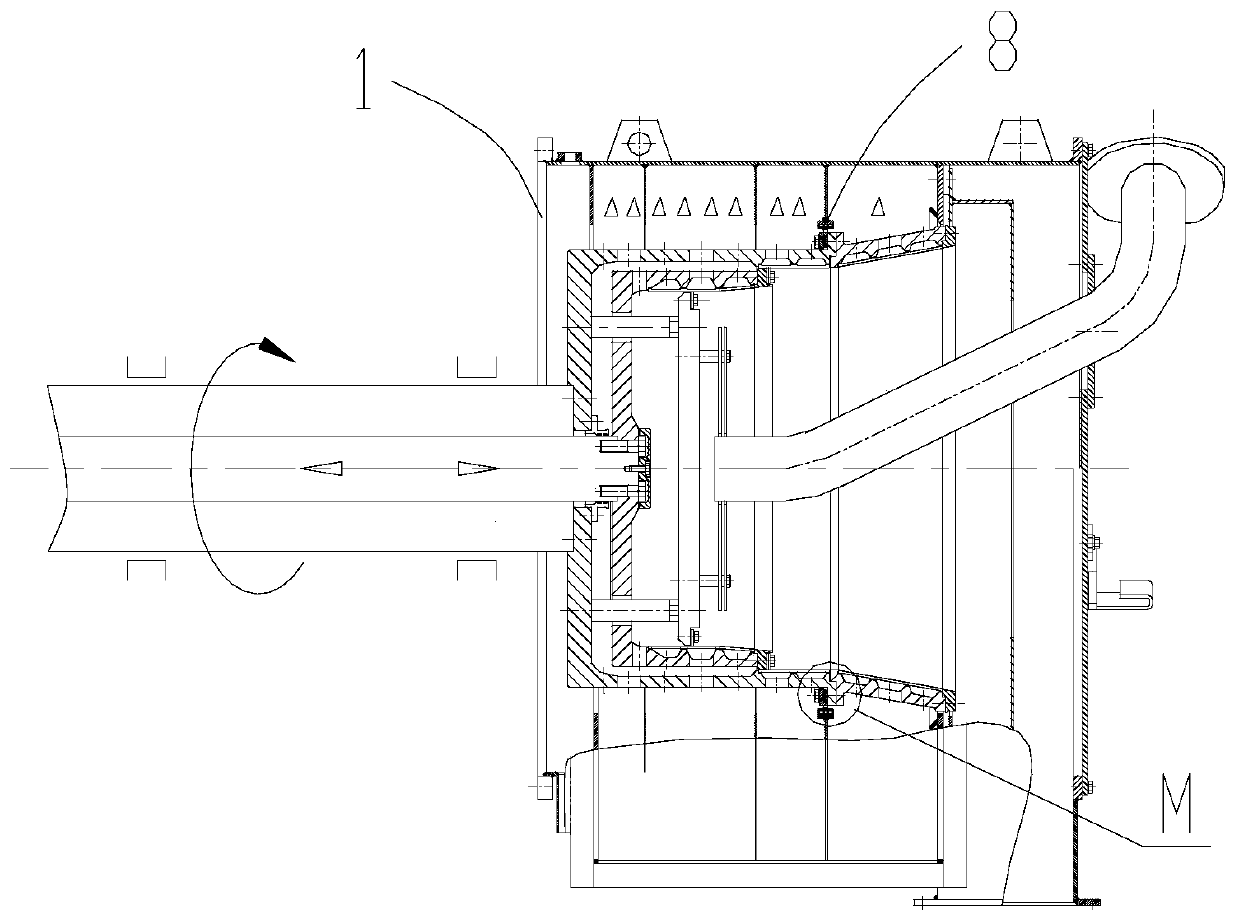

[0029] The working state structure of the two-stage pusher centrifuge is as follows: figure 1 As shown, the outside is the casing 1, and the outer drum 2 and the inner drum 3 are arranged coaxially inside the casing, wherein the inner drum 3 makes axial repeated movements while rotating with the outer drum 2, and the material is fed from the feed The tube 6 is sent to the screen of the inner drum 3, and the dehydrated liquid of the high-speed centrifuge comes out from the liquid outlet 5, and the solid formed filter cake is pushed axially by the inner drum 3 to come out from the solid outlet 7.

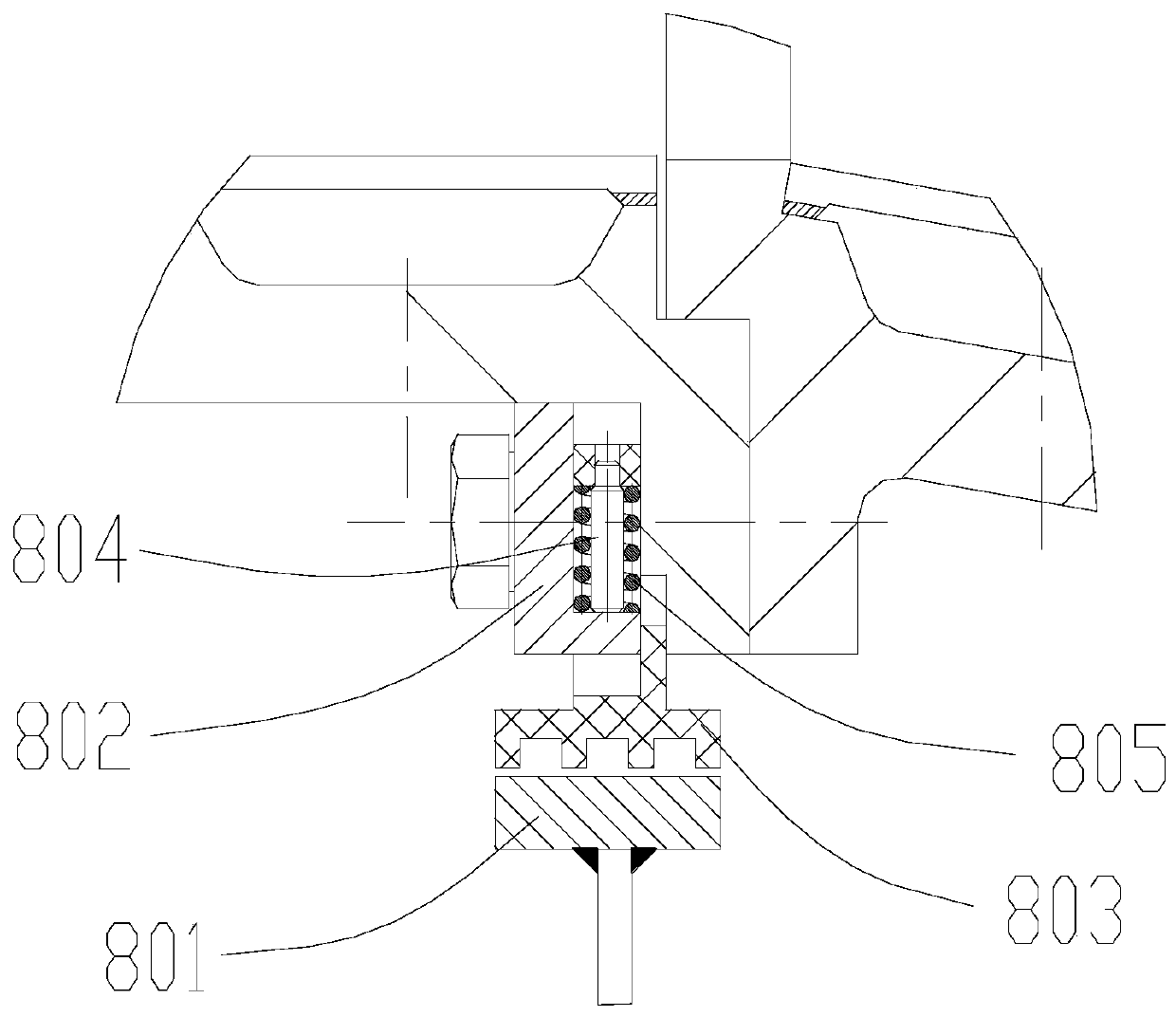

[0030] This embodiment is a double-stage pusher centrifuge anti-leakage sealing method, which creates negative pressure in the liquid chamber between the casing 1 and the outer drum 2, so that the outer drum 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com