A static pressure system damping copper tube manufacturing device

A technology for manufacturing devices and copper tubes, which is applied in the field of manufacturing devices for damping copper tubes in static pressure systems, can solve problems such as poor manufacturing accuracy, and achieve the effects of consistent pitch, uniform and smooth copper tubes, and beautiful precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

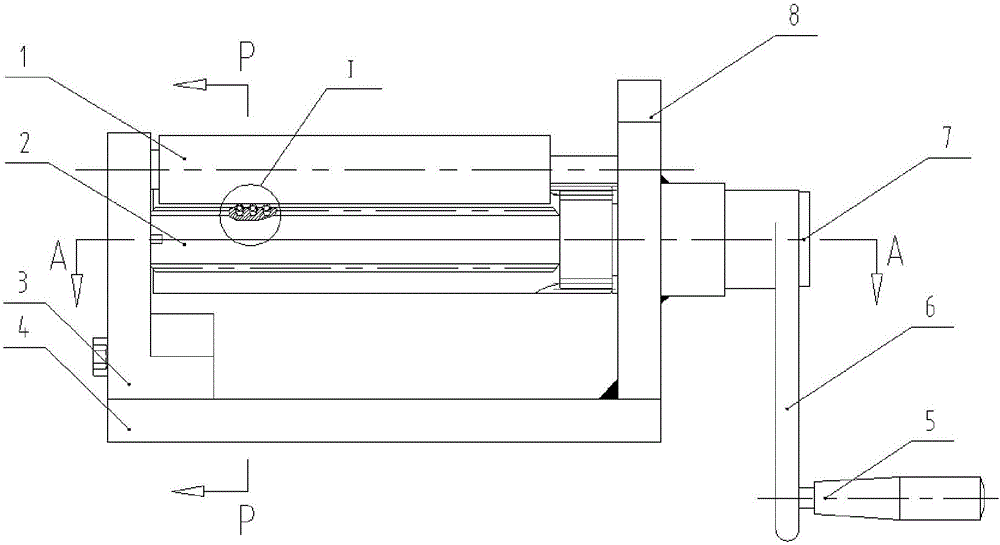

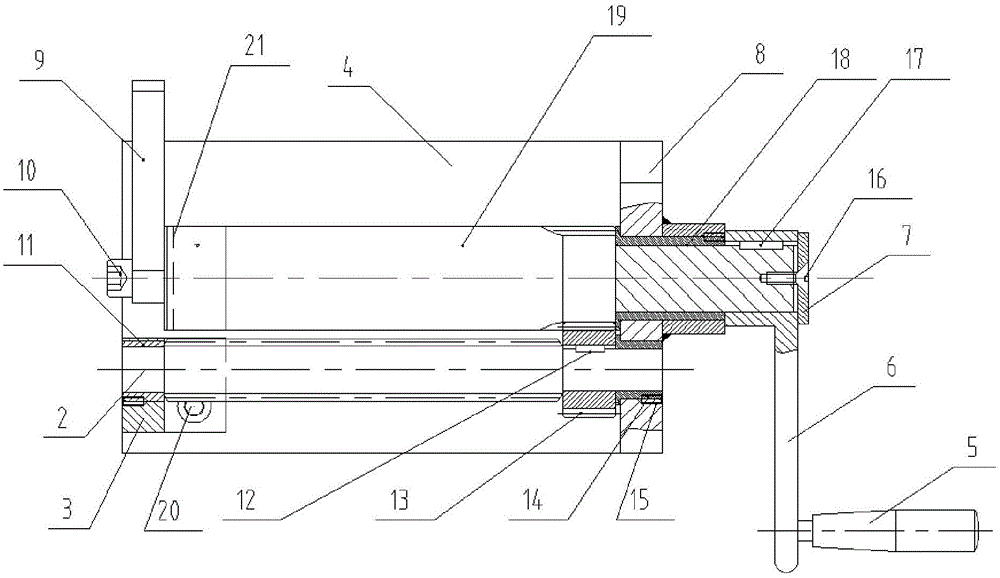

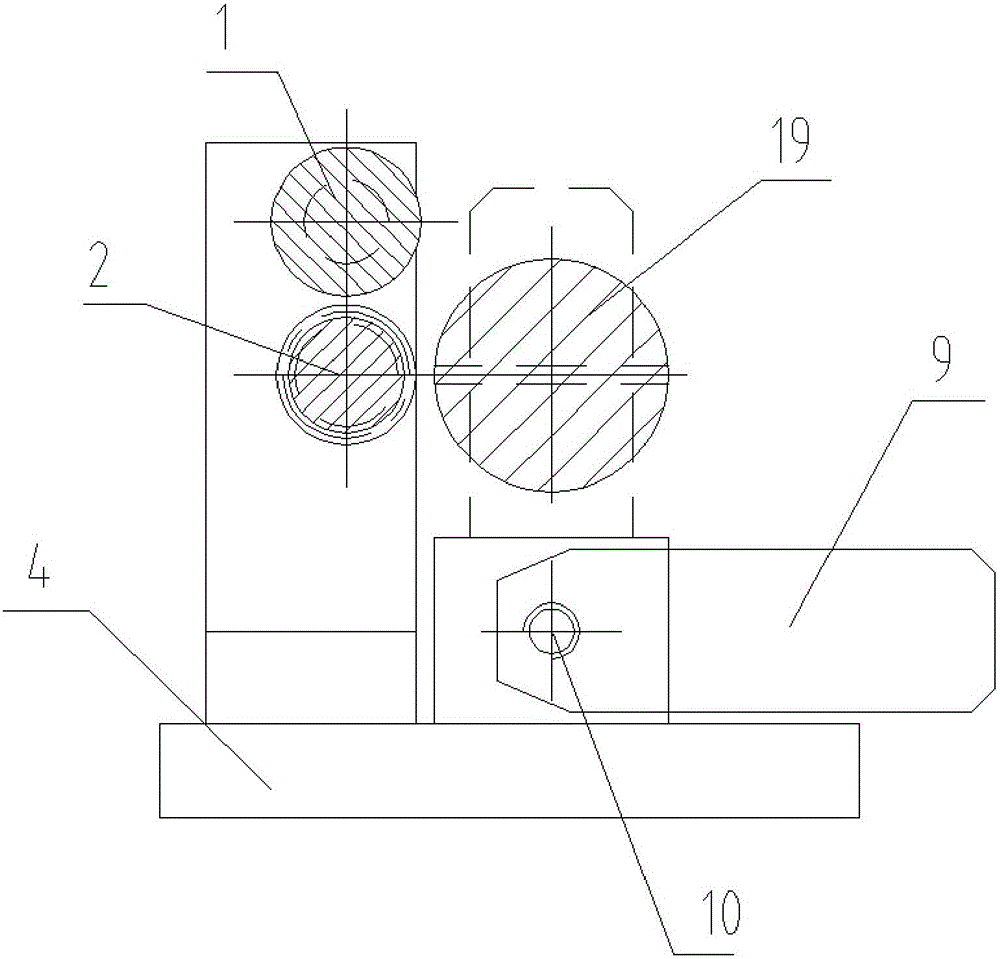

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0018] Such as Figures 1 to 4 As shown, the device for manufacturing a damping copper tube for a static pressure system is characterized in that it includes a bottom plate 4, a left bracket 3 and a right bracket 8 are respectively arranged on the bottom plate 4, and the gear shaft 19 and the screw mandrel 2 are correspondingly installed on the left bracket 3 and the right bracket 8, the gear 13 at one end of the screw mandrel 2 meshes with the end of the gear shaft 19, the end of the gear shaft 19 is also provided with a groove 21, and the end of the gear shaft 19 stretching out from the right bracket 8 is provided with a handle 6. The handle 6 is provided with a handle 5, the left bracket 3 is also provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com