Precision centralized positioning tool

A center positioning and high-precision technology, applied in the field of high-precision center positioning tooling, can solve the problems of large deviation of coaxiality between the shell bearing and the mounting hole of the rear cover, low precision, and difficulty in disassembly and assembly, so as to ensure repeated positioning accuracy. , The effect of flexible rotation and prevention of entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

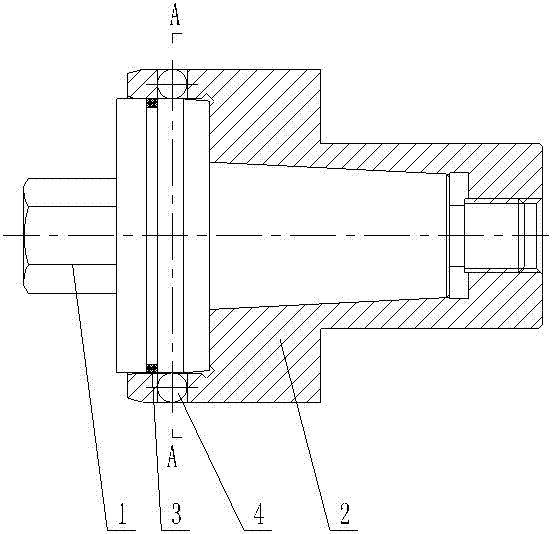

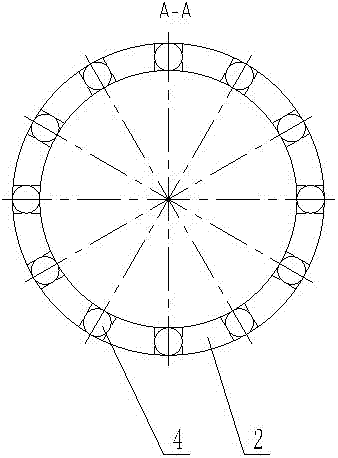

[0014] Such as figure 1 and 2 As shown, the high-precision center positioning tool of the present invention includes a positioning mandrel 1 and a taper sleeve mandrel 2. The positioning mandrel 1 is coaxially embedded in the taper sleeve mandrel 2 and is positioned and matched to ensure the repeatability of the tooling. Positioning accuracy, twelve positioning steel balls 4 are arranged at the same cross-section and equal angles between the tapered sleeve mandrel 2 and the positioning mandrel 1, and the positioning steel balls 4 and the tapered sleeve mandrel 2 adopt a gapless fit, which can ensure The positioning steel ball 4 is flexible, and an O-ring 3 is provided between the taper sleeve mandrel 2 and the positioning mandrel 1 to effectively prevent the entry of iron filings and ensure the flexible rotation of the positioning steel ball 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com