Quantitative powder loading system

A quantitative feeding and powder technology, which is applied in the direction of selling raw material supply devices, clay preparation devices, mixing operation control devices, etc., can solve the problem of poor feeding accuracy and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

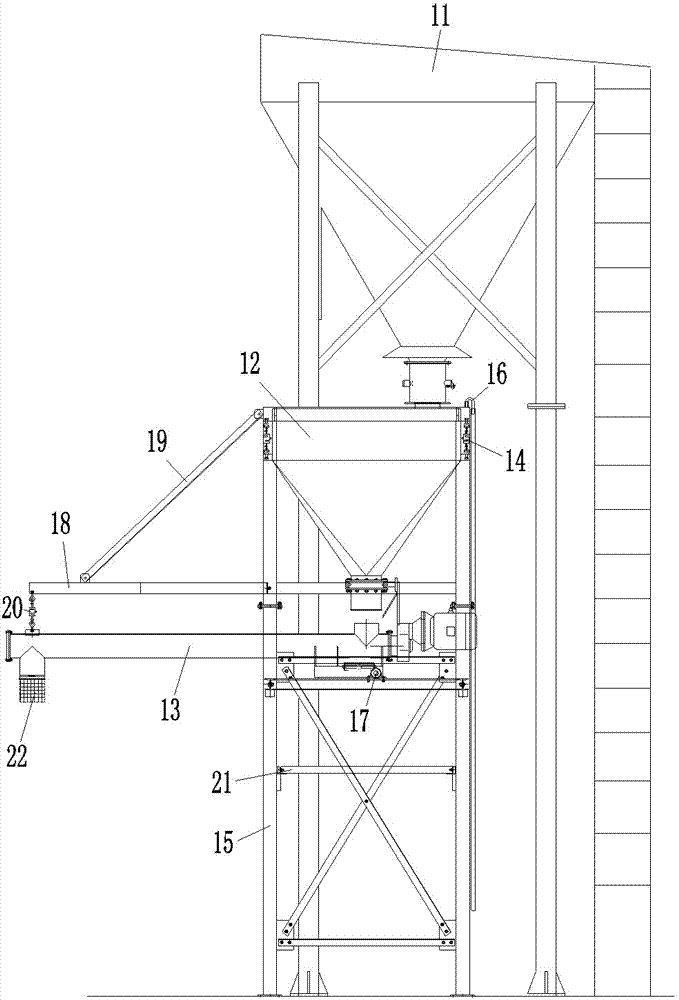

[0014] The embodiment of powder quantitative feeding system, such as figure 1 As shown, the powder quantitative feeding system includes a storage bin 11 , a transition bin 12 and a powder weighing device 13 .

[0015] The storage bin 11 is a powder warehouse with an outlet at the bottom and a valve (not shown in the figure) at the outlet. The valve is controlled by a switch, and the switch specifically adopts a load cell 14 .

[0016] The transition bin 12 is located between the storage bin 11 and the powder weighing device 13. The inlet of the transition bin 12 is connected to the outlet of the storage bin 11, and the outlet is connected to the powder weighing device 13. When in use, the storage The powder in the bin 11 first falls into the transition bin 12, and then it is output from the transition bin 12 by the powder weighing device 13, and the load cell 14 as a valve switch is connected with the transition bin 12, when the transition bin 12 When the weight of the powder...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap