Ink box chip, ink box and ink-jet printer

An ink cartridge chip and printer technology, which is applied in the printing field, can solve the problems of printer stylus breakage, thin structure, and increased user costs for users, and achieve the effects of improved processing and production, good positioning and connection, and protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Cartridge chip embodiment:

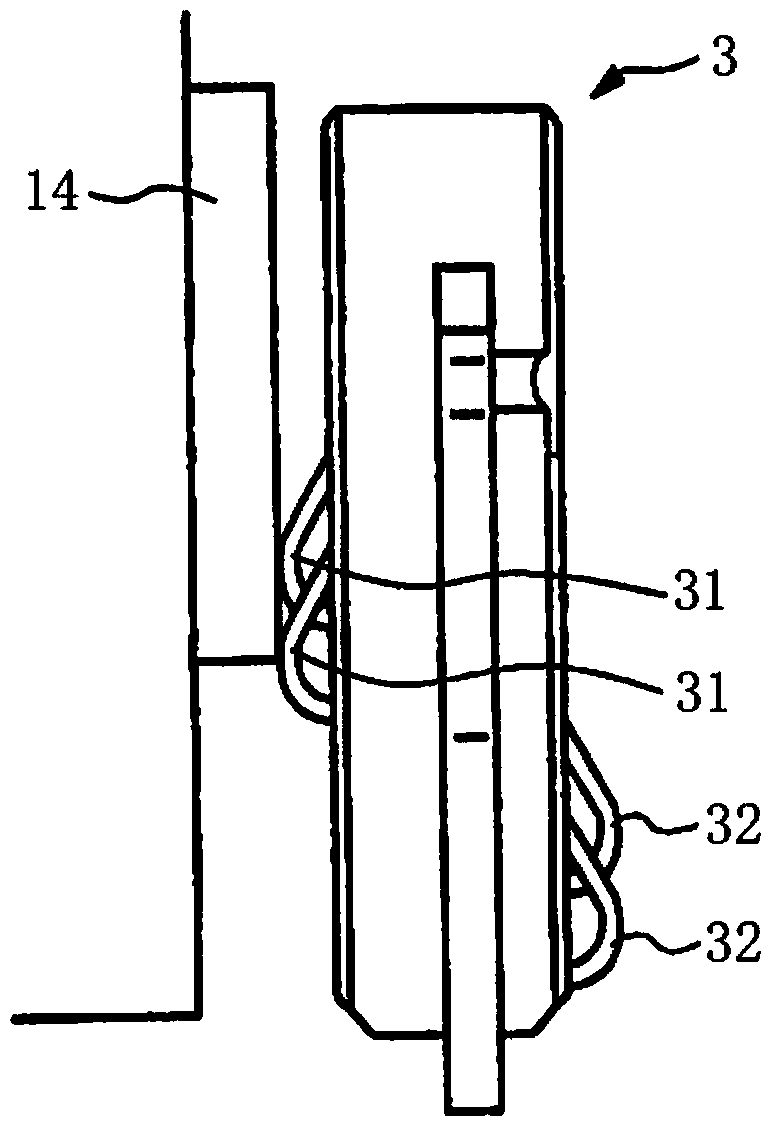

[0041] refer to Figure 6 , Figure 6 It is a structural diagram of the ink cartridge chip 4. The ink cartridge chip 4 includes a chip substrate 43, on which an electronic module is installed, the electronic module includes a controller and a memory, the controller is used to control the read and write operations of the memory, and the memory is used to store the production date, manufacturer, equipment code, etc. Fixed information, but also store variable data that needs to be updated, such as the remaining ink level and the number of printed pages. The electronic module can be an application-specific integrated circuit or a microcontroller such as a single-chip microcomputer.

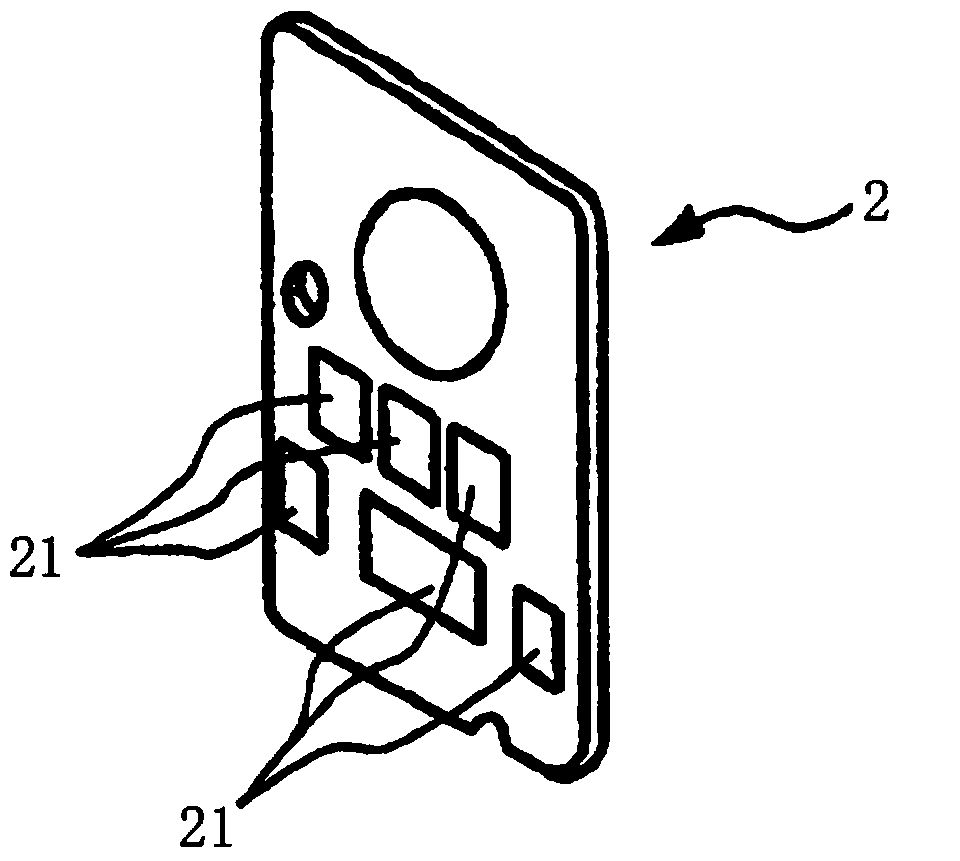

[0042] Chip contact assemblies are also welded on the chip substrate 43, and the chip contact assemblies include five lower row chip contacts 41 and four upper row chip contacts 42, the lower row chip contacts 41 and the upper row chip contacts 42 are both It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com