Automatic tank top balance air jacking method and jacking device for LNG storage tank

An automatic balancing and storage tank technology, applied in large-capacity bulk material warehouses, building types, buildings, etc., can solve problems such as failure to achieve automatic balancing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

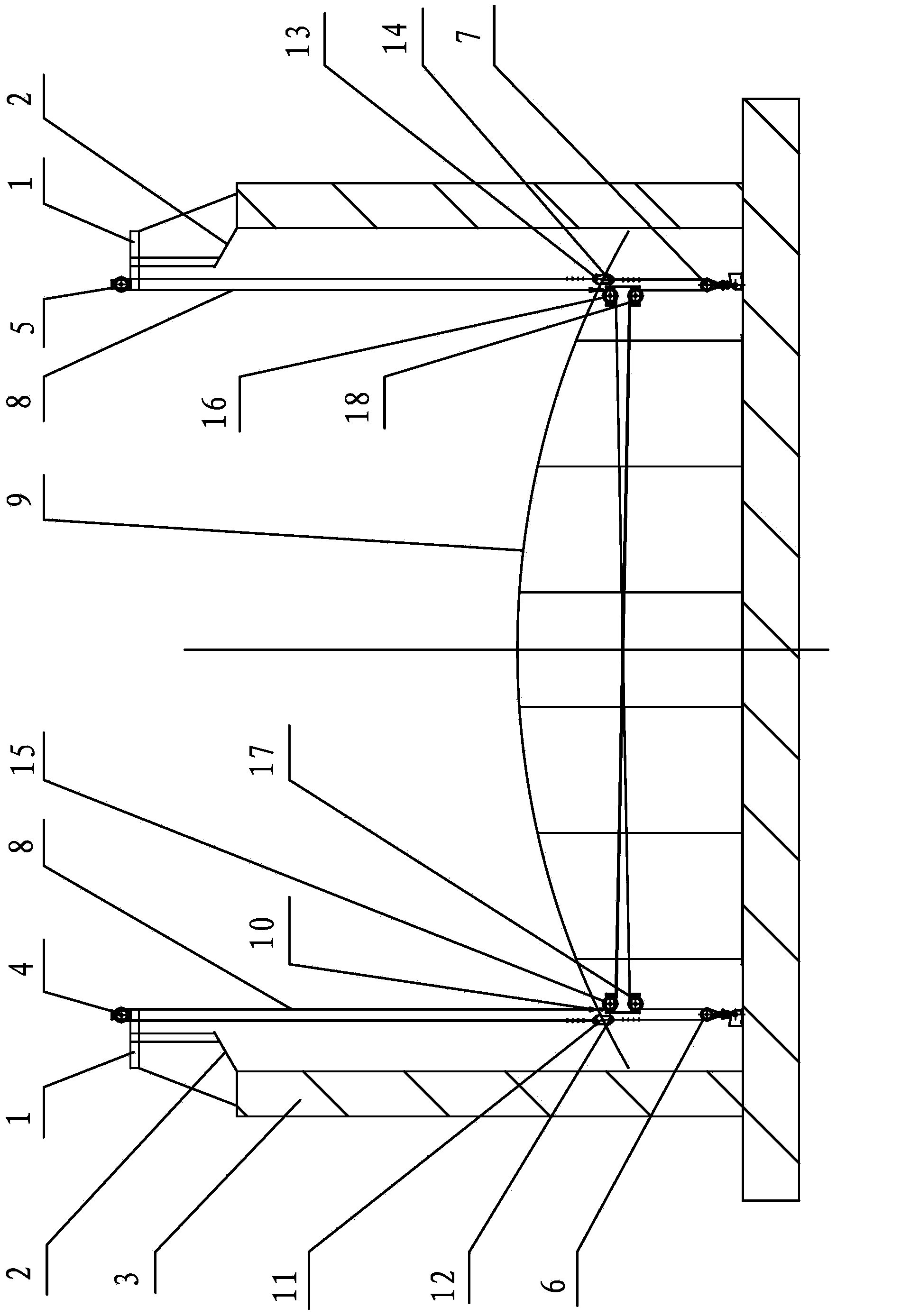

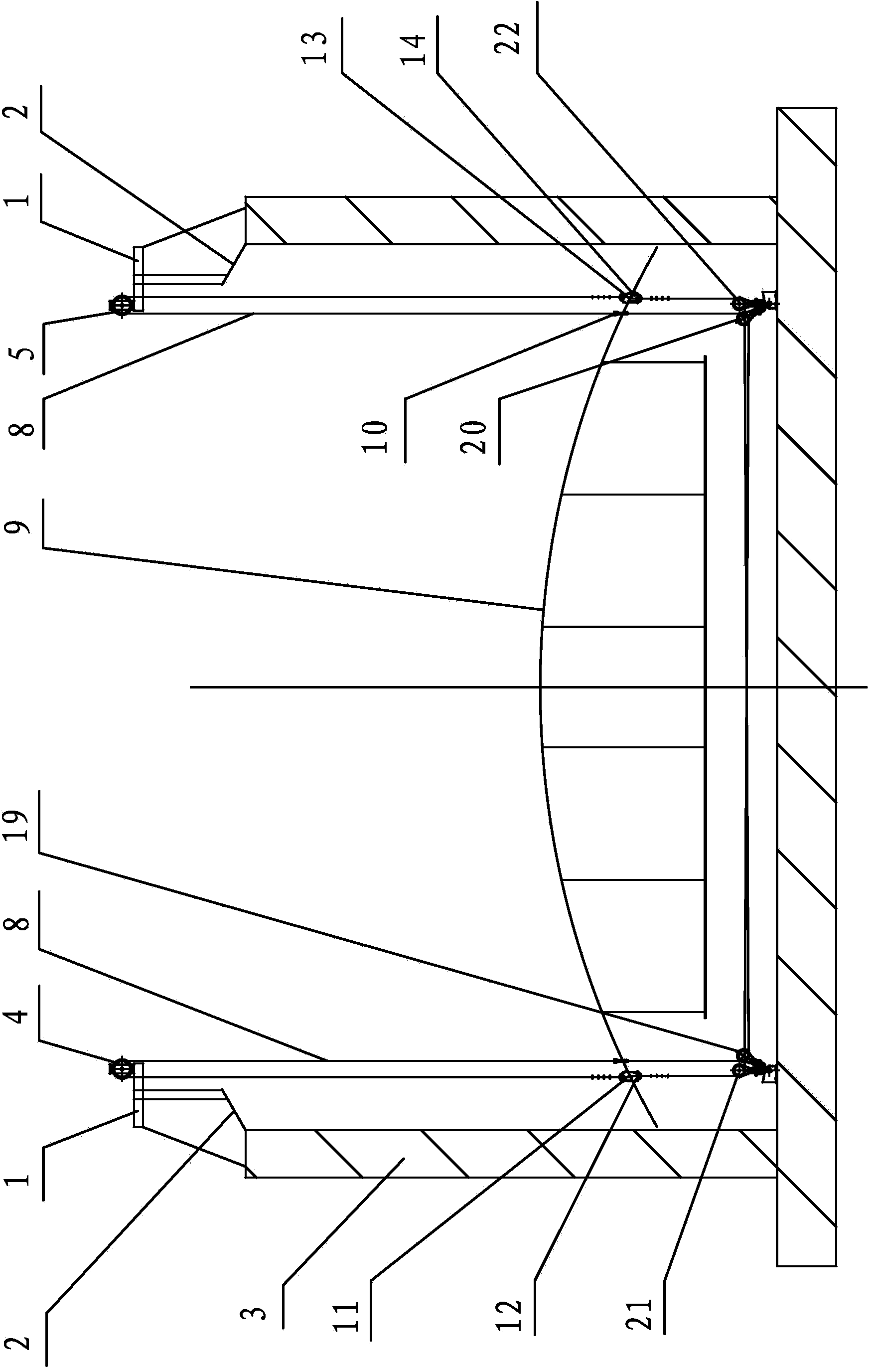

[0018] The technical solutions of the present invention will be further described below in conjunction with the implementation manners shown in the accompanying drawings.

[0019] The method for lifting the top of the LNG storage tank with automatic balance gas of the present invention is to lift the top 9 of the tank to the top of the storage tank 3 by adopting air intake at the bottom of the storage tank 3 and make it connected to the pressure ring 2. During the jacking process of 9, the following two wire rope transmission mechanism schemes are adopted, which can automatically guide and balance the tank roof 9 without counterweight, so that each group of radially symmetrical points on the tank roof 9 is located between the steel wire rope 8 and the tank roof 9. Correspondingly arranged pulleys and pulley blocks form a closed transmission loop and restrict each other, thereby achieving automatic balance, so that the tank top 9 is lifted synchronously and does not tilt.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com